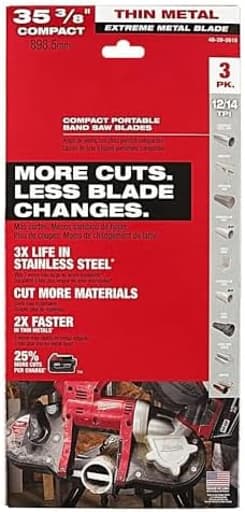

Features

- More cuts and less blade changes

- 3X life in stainless steel and other metals

- Fast cutting in thin metals

- 25% more cuts per charge

- Variable TPI for cutting various metal thicknesses

- Optimized tooth design for clean cuts

Specifications

| Number Of Teeth | 434 |

| Tpi | 12/14 |

| Blade Length | 35.375 in |

| Pack Qty | 3 |

| Size | 35 3/8" |

| Weight | 0.113 lb |

| Height | 0.5 in |

| Width | 11.26 in |

| Material Thickness | Thin Metal |

| Material Application | Thin Metal |

Related Tools

Related Articles

These band saw blades are designed for cutting metals, offering longer life and fewer blade changes.

Milwaukee Extreme Metal Band Saw Blades 3PK Review

As a long-time user of Milwaukee tools, I was eager to get my hands on the Milwaukee Extreme Metal Band Saw Blades 3PK (model 48-39-0619). Known for their durability and efficiency, Milwaukee tools have often been my go-to for various projects. However, my experience with these specific band saw blades has been a mixed bag.

The first thing I noticed about these blades is their packaging and presentation. They come in a neat pack of three, which is convenient for anyone who needs a ready supply of blades. The packaging highlights some impressive features, such as a 3X longer life in stainless steel and other metals, fast cutting in thin metals, and a variable TPI for cutting various metal thicknesses. These sounded promising, especially for someone who frequently works with different types of metals.

Upon installing the blade on my Milwaukee cordless band saw, the process was relatively straightforward. The blade has a length of 35.375 inches, which fits perfectly on the tool. However, I did experience some initial difficulties. The blade seemed to struggle with staying on the pulleys, which was quite frustrating. I had to make several adjustments to ensure it was properly seated. This was a bit of a letdown, considering the expectation of plug-and-play ease with Milwaukee products.

Once I got the blade properly installed, I started with some light cutting tasks. The first few cuts through thin metal were smooth and efficient. The blade's optimized tooth design did deliver clean cuts, and I noticed that it was faster than some other blades I’ve used in the past. However, as I moved on to thicker materials, the performance began to wane. The blades dulled quickly, sometimes after just a couple of cuts. This was particularly noticeable when cutting through stainless steel and cast iron.

Durability is a significant concern with these blades. I found that they snapped at the welds during some of the heavier cutting tasks. This not only disrupted my workflow but also raised safety concerns. A blade snapping mid-cut can be dangerous, and it’s something no user wants to experience. The blades also seemed prone to developing cracks along their length, which further compromised their integrity.

One of the more frustrating aspects was the inconsistency in blade quality. While some blades performed decently, others were practically unusable from the get-go. One of the blades in my pack had teeth that were cut in the wrong direction, rendering it completely ineffective. This level of quality control is disappointing, especially from a brand like Milwaukee.

In terms of cutting efficiency, I found the blades to be a mixed performer. For lighter tasks like cutting through EMT (Electrical Metallic Tubing) and copper pipes, they worked fine. The cuts were clean, and the tool performed well. However, when it came to tougher materials like threaded rods and rebar, the blades fell short. They dulled quickly and often broke before I could complete the cuts. This inconsistency makes it hard to rely on these blades for more demanding projects.

On a positive note, when the blades were new and sharp, they did provide more cuts per charge, which is a testament to their efficiency. This is particularly beneficial for cordless tool users who need to maximize battery life. However, the quick dulling negates this advantage, as frequent blade changes become necessary.

I also tested the blades on some cast iron drain pipes, a common task for plumbers. Initially, the blades exceeded my expectations, cutting through the cast iron with relative ease. However, this performance was short-lived as the blades dulled rapidly, requiring frequent replacements to maintain cutting efficiency.

Considering the price point, these blades are not cheap. The cost of frequent replacements can add up quickly, making them a less economical choice in the long run. When compared to other brands like Lenox and Morse, which I have used in the past, these Milwaukee blades don’t quite measure up in terms of durability and overall performance.

In conclusion, while the Milwaukee Extreme Metal Band Saw Blades 3PK has some commendable features like fast cutting in thin metals and more cuts per charge, the issues with durability and consistency overshadow these benefits. The blades' tendency to dull quickly and snap at the welds makes them a less reliable choice for heavy-duty tasks. If you’re working on lighter projects or require occasional use, these blades might suffice. However, for more demanding applications, I would recommend exploring other options that offer better longevity and consistent performance.

Given the mixed results and the high cost of frequent replacements, I find it challenging to fully endorse these blades. Milwaukee has a reputation for quality, but in this instance, they seem to have missed the mark. For now, I would suggest looking into alternatives that provide better durability and reliability for your metal cutting needs.

Project Ideas

Business

Custom Metal Fabrication Service

Offer a custom metal cutting and fabrication service to local businesses and individuals. Use the band saw blades to provide precise cuts and high-quality finishes for various metal projects.

Metal Signage Business

Start a business specializing in custom metal signs for businesses, homes, and events. The band saw blades can help you cut detailed and intricate designs, making your signs stand out.

Metal Repair and Maintenance Service

Provide a repair and maintenance service for metal items such as fences, gates, and machinery. The durability and precision of the band saw blades will make your service efficient and reliable.

Metal Workshop Classes

Offer workshops and classes teaching people how to work with metal. Use the band saw blades to demonstrate cutting techniques and safety practices, and help students create their own metal projects.

Online Metal Cutting Templates

Create and sell downloadable templates for metal cutting projects. Customers can purchase and use these templates to create their own metal art, furniture, or other items, using their own band saws and blades.

Creative

Metal Art Sculptures

Use the band saw blades to cut intricate shapes out of metal sheets and create beautiful metal art sculptures. These can be wall hangings, garden decorations, or even custom commissions.

Custom Metal Furniture

Design and build custom metal furniture pieces like coffee tables, chairs, or shelves. The band saw blades will allow for precise cuts, enabling you to create unique and sturdy furniture.

Metal Jewelry Making

Craft unique pieces of metal jewelry such as bracelets, rings, or necklaces. The band saw blades can help in cutting precise and intricate designs, giving your jewelry a professional finish.

Upcycled Metal Projects

Use scrap metal and old metal items to create upcycled projects such as lamps, candle holders, or coat racks. The band saw blades will make it easy to cut and shape the metal to fit your designs.

Metal Puzzle Craft

Create complex and engaging metal puzzles. Cut the metal into various shapes and sizes to form interlocking pieces that can be assembled into a finished puzzle.