Features

- Aluminum oxide abrasive that exposes fresh grain for continued cutting

- Proprietary material mix intended to extend disc life

- Fiber backing to resist tearing

- Compatibility with quick-lock backing pads for faster disc changes (depends on arbor)

- Intended for metal surface finishing, weld and edge blending, and surface preparation

Specifications

| Arbor Size | 7/8 in |

| Diameter | 4-1/2 in |

| Grit Size | 16 |

| Maximum Rpm | 13300 |

| Abrasive | Aluminum oxide |

| Backing | Fiber |

Related Tools

Related Articles

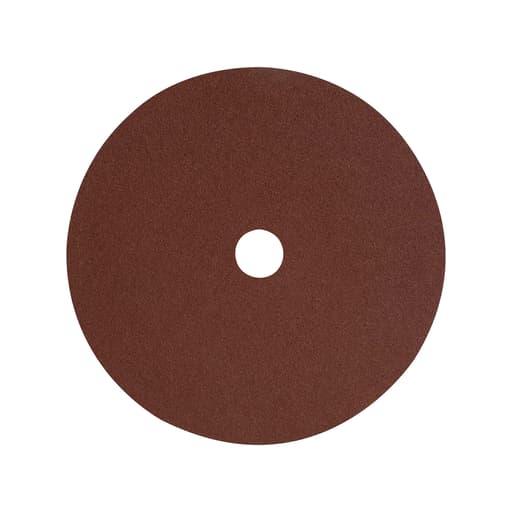

Fiber discs with aluminum oxide abrasive bonded to a fiber backing. The abrasive fractures in use to expose fresh cutting edges for consistent material removal. The fiber backing reduces tearing. Discs are intended for use with compatible fiber-disc backing pads; quick-lock systems may be used where the arbor specification allows.

DeWalt Aluminum oxide fiber disc (4-1/2 in, 16 grit) Review

What I used it for

I reached for the DeWalt 16‑grit fiber disc when I needed to tear into weld beads, knock down flame-cut edges, and strip mill scale on mild steel plate. On a 4‑1/2 in grinder, a 16‑grit disc is the brute-force option—more like a scalpel with teeth than a finishing tool. If your workday involves heavy stock removal or fast prep before fabrication, this disc sits right in that lane.

Setup and compatibility

This is a standard 7/8 in arbor fiber disc, so it slips onto any typical 4‑1/2 in angle grinder that uses a backing pad and clamping nut. I paired it with a hard backing pad for maximum support; the hard pad keeps the disc flatter and helps the abrasive bite without “dishing” under pressure. If you prefer a little more compliance for blending, a medium pad works, but with 16 grit I find a hard pad keeps the gouging in check.

If your grinder uses a quick‑lock style backing pad, the disc plays nicely—as long as the arbor accommodates 7/8 in center holes. The max RPM is 13,300, so it’s within spec for most 4‑1/2 in grinders.

Quick setup tips:

- Use a guard that fully covers the disc perimeter.

- Keep the work angle around 10–15 degrees. Flatter digs less, steeper gouges more.

- Do a couple of short passes on scrap to “open” the grain before you attack a visible surface.

Cutting performance

At 16 grit, this DeWalt disc is unapologetically aggressive. On mild steel welds, it bites fast and tracks straight, even across hard toes. I was able to flatten MIG beads in a few steady passes without resorting to a grinding wheel. Compared to a 36‑grit fiber disc, it removes material faster and runs cooler at the same pressure—simply because the bigger grain clears chips more easily.

The aluminum oxide grain fractures as it wears, and that self-sharpening effect is noticeable. As long as I maintained the correct angle and didn’t bear down too hard, the disc kept cutting instead of glazing. The cut stays predictable, which matters when you’re flattening a weld without wanting to dish the surrounding parent metal.

On rusty steel or heavy scale, the disc still pulls its weight, but you’ll feel more resistance as the abrasive tries to get under the oxide layer. In those cases, I lighten up on pressure and increase my traverse slightly to avoid heat build-up. The coarse grit will plow scale off; just don’t stall the disc.

Heat and control

Fiber discs can get hot and fail prematurely if you push them like grinding wheels. This one likes firm but measured pressure. I got the best control with short, overlapping passes and a consistent angle. Sparks were abundant—normal for this grit—so a face shield is a must. Compared to a hard grinding wheel, the overall feel is smoother and there’s less chatter transmitted into the hands, especially when working across uneven weld crowns.

Durability and wear

The fiber backing on this disc holds up better than many bargain discs I’ve used; it’s less prone to edge fraying as long as you stay off sharp corners. Catch the disc edge on a protrusion, and you can still tear it—that’s the nature of fiber discs—so approach corners with a lighter touch and a slightly flatter angle.

The life you get depends heavily on material and technique:

- On mild steel, life is respectable. The disc keeps its bite and wears evenly.

- On stainless, aluminum oxide will cut but loses sharpness faster; expect a shorter run before it feels tired.

- On aluminum and other non‑ferrous metals, it loads quickly. I don’t recommend this disc for those; a dedicated non‑ferrous abrasive or a lubricant is a better route.

I wouldn’t claim it rivals premium ceramic discs for longevity, but for an aluminum‑oxide option it holds up well, provided you let the grit do the work instead of leaning on it.

Surface quality and follow‑up

This is an aggressive scratcher, and it leaves a deep 16‑grit pattern. That’s appropriate for stock removal, not final blending. After knocking down welds with this disc, I step to a 36/40 grit fiber disc or a 60‑80 grit flap disc to refine the surface. If you need a near‑finish blend on stainless or visible exterior work, plan on at least two subsequent abrasive steps after the 16‑grit pass.

A few blending pointers:

- Cross‑hatch your passes to avoid troughs.

- Transition to finer grit while there’s still a slight high spot; don’t dig a low crater you’ll chase later.

- Keep the pad moving. Dwelling in one spot with 16 grit is how you make flats and waves.

Safety and speed

With a max rating of 13,300 RPM, the disc is comfortably within the limit of most compact grinders. Still, the backing pad isn’t optional—never run fiber discs against a bare flange. The pad supports the abrasive and dissipates heat; without it, you’ll shred the disc and potentially injure yourself.

Keep an eye on the disc diameter as it wears. If you run near the guard, re‑orient or swap early rather than forcing it into tight spots where you’ll inevitably catch an edge.

Where it shines—and where it doesn’t

Shines:

- Rapid weld and edge knockdown on mild steel

- Prepping hard edges before beveling

- Stripping heavy mill scale or rust prior to fabrication

- Situations where a grinding wheel feels too harsh and a 36‑grit flap disc feels too slow

Doesn’t:

- Final surface blending or cosmetic work

- Non‑ferrous metals (load‑up risk)

- Tight inside corners or fillets—the disc edge is easy to catch and damage

- Stainless production work, where a ceramic disc would outlast and outpace it

Value and buying notes

As an aluminum‑oxide option, this disc hits a sensible balance: lower cost than ceramic with enough bite to make fast work of steel. If you’re in a production environment grinding stainless all day, ceramic discs still win on cost per part. For general fabrication, repair work, or a shop that cycles between tasks, this DeWalt offers good performance without the premium price tag.

A quick purchasing reminder: fiber discs are often sold in multi‑packs and sometimes as singles. Confirm the quantity before you check out, and make sure you’ve got a compatible 7/8 in backing pad on hand. Store the discs flat and dry; moisture can warp fiber backings and shorten life.

Practical tips for best results

- Use a hard backing pad for fastest removal; switch to medium for light blending.

- Maintain a shallow angle (10–15 degrees) and steady motion to prevent gouging.

- Lighten pressure as the disc thins; forcing a worn disc is how you burn it out.

- Don’t use on aluminum without a lubricant, and better yet, choose a non‑loading abrasive designed for non‑ferrous metals.

- Step down through grits if you care about the final appearance; 16 grit is just the opener.

Recommendation

I recommend the DeWalt 16‑grit fiber disc for anyone who needs fast, controlled stock removal on mild steel with a 4‑1/2 in grinder. It cuts aggressively, holds together under sensible technique, and stays consistent as the grains fracture and renew. It isn’t a finishing tool and it isn’t the best match for non‑ferrous or heavy stainless work, but as a first pass for weld removal and surface prep, it’s a capable, straightforward consumable that earns a spot in the drawer. Confirm you’re buying the right quantity, pair it with a proper backing pad, and it will do exactly what a 16‑grit disc should: move metal quickly without unnecessary drama.

Project Ideas

Business

Mobile Rust & Paint Stripping

Offer on-site surface prep for gates, fences, trailers, and railings. Use the disc to remove thick rust, flaking paint, and weld scale quickly, then follow with finer grits for prime-ready surfaces. Price per square foot with travel fee; upsell priming and protective topcoats.

Weld Cleanup Subcontracting

Partner with small fab shops to handle deburring, weld blending, and edge radiusing. Quick-lock pads speed disc swaps, improving throughput. Bill per piece or batch; provide consistent finishes so fabricators can focus on fit-up and welding.

Fleet & Equipment Prep Service

Prep steel truck bodies, dump beds, plows, and farm implements for repair and repaint. Remove corrosion at seams and edges, feather old coatings, and create mechanical keying. Sell maintenance contracts with seasonal visits and corrosion-inhibiting coatings.

Industrial-Style Furniture Line

Create and sell metal furniture and signage featuring a deliberate coarse texture. Use 16-grit for rapid shaping and weld blending, then step to 60/120 for touch surfaces. Market the rugged aesthetic; offer custom logos/monograms and clear or blackened finishes.

Tool & Hardware Reconditioning

Buy rusty vises, clamps, jacks, mower decks, and hand tools. Strip rust and paint, blend casting flash and sharp edges, repaint, and resell with before/after photos. Offer local pickup and a rust-prevention add-on (oil or clear coat).

Creative

Textured Reclaimed Steel Wall Art

Use the 16-grit disc to aggressively shape, de-scale, and texture reclaimed plate or scrap steel. Carve gradients, feather edges, and create highlight zones that catch light. After shaping and blending welds, apply patina (vinegar/salt or commercial) and seal with clear coat for a bold industrial piece.

Industrial Coffee Table Base

Fabricate a base from angle, tube, or small I-beam offcuts. Use the disc to bevel edges for welding, then blend and radius all welds for a tactile, professional finish. Leave a uniform scratch pattern for a clear-coated raw-steel look that pairs with wood, glass, or concrete tops.

Knife/Garden Tool Rough Shaping

Profile blades or garden tools from reclaimed spring steel or mower blades. The 16-grit cuts fast to remove rust, mill scale, and excess stock, establish bevels, and round tangs before moving to finer grits for sharpening and final finish.

Layered Sheet Metal Sculpture

Cut abstract shapes from thin steel sheet, then use the disc to chamfer perimeters, blend overlaps, and create contrasting textures. Spot-weld layers, blend those welds, and finish with selective polishing or patina to emphasize depth.

Vintage Gear Refurb (Toolbox/Bike/Grill)

Strip failing paint and heavy rust from steel toolboxes, bike frames, grills, or brackets. The coarse disc creates an even tooth for primer, leading to durable repaints. Blend dents and weld repairs for a cleaner restoration.