Features

- Provides up to 15 inches of additional support for ripping long boards and large panels

- Hardened metal construction

- Aluminum mounting brackets

- Adjustable by sliding fence and hand-tightened lock knob

- Simple installation without special tools

Specifications

| Support Extension | Up to 15 inches |

| Materials | Hardened metal support; aluminum mounts |

| Compatibility | Designed for the SPT99 10 in. heavy duty worm drive table saw with stand |

| Installation | Slide fence to position and hand-tighten lock knob |

| Weight (Lb) | 0.40625 |

| Model/Sku | SPT00B |

Related Tools

Related Articles

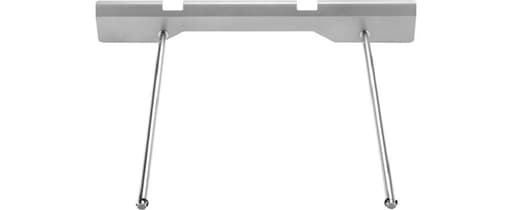

Rear outfeed support that extends the table saw surface by up to 15 inches to help support long boards and large panels. It uses hardened metal components with aluminum mounting brackets, mounts to the saw stand, and is adjustable. Positioning is set by sliding the fence to the desired location and tightening a lock knob by hand.

Skil Table Saw Rear Outfeed Support Review

Why I added an outfeed support to my jobsite saw

On a jobsite table saw, the workpiece almost always grows as soon as you hit the switch—2x lumber seems longer, sheet goods feel heavier, and keeping a cut tracking straight becomes more about control than horsepower. That’s why I added the Skil outfeed support to my SPT99 stand. It’s a simple accessory—just a rear support arm that extends the surface by up to 15 inches—but in daily use it does exactly what I need most: buy me a margin of control at the end of the cut.

Setup and compatibility

Installation was straightforward. The support mounts to the stand using aluminum brackets, and positioning is set by sliding and locking it with a hand knob. No special tools, no drilling. If you’re already running the SPT99 with its wheeled stand, this is essentially plug-and-play. I had it installed, aligned, and feeding stock in under 15 minutes.

Because the support references the stand rather than the table casting, setup is largely about getting the planes to agree. I set the saw on a flat patch of slab, attached the support, then ran a straightedge across the table and outfeed to check for co-planarity. A couple of minor adjustments later, the transition felt seamless—no lip to catch thin stock and nothing proud that would lift the trailing end of a panel.

A quick note on portability: adding the outfeed support didn’t meaningfully change how the stand folds, rolls, or stores. It’s light enough that I barely notice it during transport, and I leave it installed most of the time.

Build quality and design

The construction is a mix of hardened metal for the support assembly and aluminum for the mounting brackets. The result is lightweight but rigid enough for the kind of work this accessory is intended to handle—ripping 2x lumber, supporting cabinet parts, and catching the trailing edge of larger panels. There’s just enough adjustability to position it where you want it without introducing slop. The hand-tightening lock knob is fast and secure; I haven’t needed to put a wrench on anything.

All that said, aluminum threads are aluminum threads. They’re fine if you treat them like a clamping mechanism, not a vise. I make it a habit to snug the knob and stop—no gorilla torque—especially when the bracket is warm from the sun. Keep the threads clean and avoid cross-threading, and I’d expect long service life.

What the extra 15 inches actually does

Fifteen inches isn’t a replacement for a full outfeed table, nor does it pretend to be. It’s a safety and control buffer. With long stock, the moment when the workpiece clears the back of the blade is when things want to pivot, tip, or bind. That’s where this support helps most. It catches the material early enough to keep the cut line steady and keep the weight from levering the workpiece down off the table.

In practice:

- Ripping 8- to 10-foot 2x stock becomes much smoother. The trailing end clears the blade without a sudden drop, and I can keep my attention on the fence line rather than bracing for the last second.

- With cabinet-grade plywood, the support doesn’t turn a compact jobsite saw into a panel saw, but it makes controlled solo rips feasible when paired with sensible infeed and side support. The key is technique: start with a solid infeed plan and let the outfeed support finish the job instead of doing all the lifting.

- On narrow rips of thin material, the continuous plane avoids snipes or catches. I was able to rip down face-frame parts without them diving at the end of the cut.

The surface is slick and doesn’t mar the work. I still give it a light coat of paste wax whenever I wax the table; the transition feels glassy and predictable.

Adjusting and using the support

Day to day, the routine is quick: extend to where I want it, confirm the lock knob is snug, and check it’s still flush. Because it references the stand, any change in ground slope or stand leg position can nudge the geometry a hair. On stable floors it never drifts. On gravel or uneven subfloors, I give it a once-over during setup.

A few practical tips that have worked well:

- Set the support a whisper lower than the saw top—about the thickness of a playing card—to ensure the work doesn’t ride up at the tail.

- Resist the temptation to extend it further than you need. Shorter extension equals less flex and more stability.

- For sheet goods, add side support to keep the panel square to the fence, then let the outfeed support catch the trailing edge so you’re not overreaching.

Performance under load

I pushed it with some typical scenarios:

- 10' treated 2x8, ripping an edge straight: The support kept the tail from sagging, and feed pressure stayed consistent. No binding, no last-second wobble.

- 3/4" melamine, 24" x 48" panel: With a helper at infeed, the outfeed support was enough to finish the cut without chipping the exit corner. Solo, I’d still add a roller stand to the outfeed side for melamine simply because it’s heavy and slick.

- 1/4" plywood strips: The continuous support helped prevent chatter or drop-off at the end of the cut.

It’s worth emphasizing: this is an aid to safe, accurate cutting, not a substitute for good stock support planning. Used that way, it materially improves results.

Durability and maintenance

After weeks of site use, the support shows minimal cosmetic wear. The hardened metal components resist dings and the brackets stay tight. I do keep an eye on the aluminum threads. My routine:

- Blow out dust from the threads at the end of the day.

- Add a dab of dry lube to the screw every few weeks.

- Hand-tighten only—no tools.

Follow those basics and the hardware should last. If you’re working in freezing conditions, thermal contraction can make knobs feel looser; check them before the first cut.

Trade-offs and limitations

- Limited extension: 15 inches is enough to stabilize, not enough to fully support large panels. Plan for additional infeed/outfeed aids with sheet goods.

- Aluminum threads: perfectly serviceable, but be gentle. Over-tightening will shorten their life.

- Stand-dependent alignment: Because it mounts to the stand, alignment depends on how level and stable the stand is. Not a flaw—just the nature of jobsite setups.

None of these are deal-breakers; they’re simply realities of a compact, portable solution.

Who benefits most

- Remodelers and framers who routinely rip long 2x material on site.

- Cabinet installers using a jobsite saw for scribing fillers and trimming panels.

- Small-shop users who wheel a saw outside and need a compact outfeed solution that doesn’t eat space.

If you already own the SPT99 with the rolling stand, this accessory makes particular sense. It integrates cleanly, adds almost no weight, and improves control in the exact moment most cuts need it.

The bottom line

The Skil outfeed support is one of those modest accessories that quietly raises the floor of your saw’s performance. It won’t turn a portable saw into a shop cabinet saw, but it reliably tames the end of the cut, makes solo work more predictable, and packs away without fuss. Installation is easy, the construction is appropriately robust, and the adjustability is simple enough that it never becomes a chore.

Recommendation: I recommend this outfeed support for any SPT99 owner who regularly rips long boards or mid-size panels and wants a portable, no-hassle way to stabilize the tail of the cut. It’s not a replacement for a full outfeed table, and you’ll still want additional support for full sheets, but as a compact solution it’s effective, durable when treated sensibly, and worth adding to the stand.

Project Ideas

Business

Custom Slat Wall Installations

Offer turnkey slat wall features for homes and offices. Use the outfeed-supported saw to batch-rip uniform slats in-house or on-site, then install with acoustic backing and integrated lighting. Package options: paint-grade MDF, white oak veneer, or stained solid wood.

On-Site Panel Breaking Service

Provide a mobile sheet-goods breakdown service for DIYers, designers, and contractors. Bring your SPT99 with the rear outfeed to client locations to safely rip full sheets into cabinet-ready parts, saving clients delivery and shop fees while you charge per cut list or per sheet.

Custom Closet Components

Produce made-to-measure closet panels, shelves, and face frames. The outfeed enables efficient, accurate long rips for carcass parts and cleats, reducing errors and rework. Sell as installed systems or as labeled flat-pack kits for installers and builders.

Flooring and Trim Rip-to-Fit Service

Partner with flooring contractors to provide precision rips for thresholds, stair nosings, and plank width adjustments. The added outfeed support improves speed and safety when processing long planks and baseboards, letting you charge per linear foot with fast turnaround.

Content + Plans Microbrand

Create build plans and short-form videos highlighting efficient long-rip workflows made safer with the outfeed. Sell downloadable plans (slat walls, tambour consoles, flat-pack furniture) and monetize via affiliate links for the SPT99 and rear outfeed accessory.

Creative

Modern Slat Wall Accent

Rip dozens of consistent, narrow strips from plywood or MDF to create a floor-to-ceiling slat wall. The outfeed support stabilizes long, thin pieces as they leave the blade, reducing chatter and kick-off so you can maintain uniform spacing and clean edges for a professional, acoustic-friendly feature wall.

Butcher Block Countertop

Mill long hardwood boards into glue-up strips for a custom butcher block. The rear outfeed keeps lengthy rips flat and aligned, improving glue-line quality and minimizing snipe. After ripping, alternate grain orientation, glue, clamp, and finish for a durable, high-end countertop or island top.

Flat-Pack Bookshelf System

Break down sheet goods into precise panels for a modular, flat-pack bookshelf. The outfeed support helps manage 8-foot rips without a second person, enabling repeatable cuts for sides, shelves, and backs that assemble with dowels or confirmats for a clean, IKEA-like result.

Outdoor Farmhouse Table and Benches

Build a sturdy outdoor dining set by ripping long 2x stock and deck boards to exact widths for tops, aprons, and seat slats. The adjustable outfeed gives you safer, smoother control of 6–10 ft boards, improving cut quality and keeping edges straight for tight joinery.

Tambour Door Media Console

Produce many thin, consistent strips for tambour doors that wrap into routed tracks. The extra rear support reduces deflection on thin rips, giving you cleaner edges and fewer burn marks—critical when assembling flexible, cloth-backed tambours for a sleek mid-century console.