Features

- Optimized for cutting concrete, brick and block

- Silicon carbide abrasive grains for material removal

- Thin wheel profile for faster, more aggressive cuts

- Fiberglass reinforcement to improve wheel strength and reduce breakage

Specifications

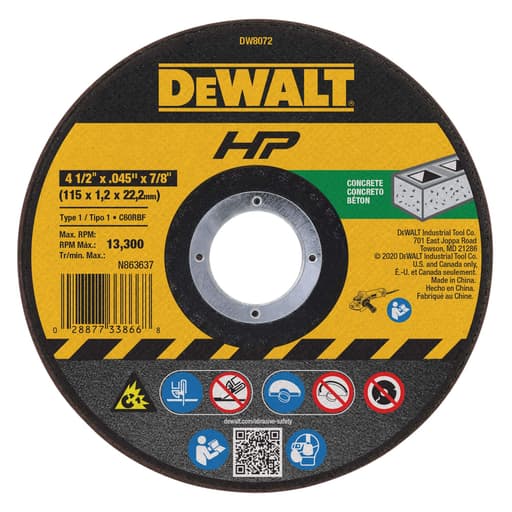

| Disc Diameter | 4-1/2 in |

| Disc Thickness | 0.045 in |

| Number Of Pieces | 25 per package |

| Abrasive Grain | Silicon carbide |

| Reinforcement | Two sheets of fiberglass |

| Intended Materials | Concrete, masonry, cast iron, ductile iron |

Related Tools

Related Articles

A reinforced abrasive cutting wheel designed for use on concrete, brick, block and other masonry. Uses silicon carbide abrasive grains and a thin-wheel geometry to remove material quickly while fiberglass layers provide strength to help resist wheel breakage.

DeWalt High-Performance Concrete Cutting Wheels Review

Why I reached for this wheel

A backyard paver project gave me a perfect chance to see what a 4-1/2-inch masonry cut-off wheel can really do. I grabbed the DeWalt concrete cutting wheel for my compact angle grinder, aiming to trim concrete pavers, score a few blocks for clean breaks, and make some notches for edging. In short: I wanted speed and control without lugging a wet saw around. This wheel’s thin, reinforced design promised quick, aggressive cuts on concrete, brick, and block—exactly the kind of work I had lined up.

Setup and compatibility

I ran the wheel on a standard 4-1/2-inch corded grinder with the guard in place. The wheel seated flat, ran true, and didn’t exhibit any noticeable wobble out of the box. It’s a resin-bonded, reinforced abrasive with silicon carbide grains and two fiberglass layers. That reinforcement matters—thin wheels can be fragile under side load, and the added stiffness helps keep things predictable when you’re plunging into hard masonry.

One practical note: at 0.045 inches thick, this is a narrow-kerf, fast-cutting wheel. It rewards a light, steady hand. Don’t lean on it or try to steer with side pressure. Keep the cut straight and let the abrasive do the work.

Cutting performance on masonry

On concrete pavers and standard brick, the wheel bites quickly. The thin profile keeps the kerf small, so you’re removing less material and building less heat compared to thicker cut-off wheels. That shows up as faster initial penetration and fewer stalls when you meet aggregate or a hard patch. Scoring a line and finishing with a second pass produced straight, predictable results, and the wheel maintained a decent rate of cut until it was about two-thirds worn.

Concrete block (CMU) cuts even easier. For trimming face shells or making relief cuts before a hammer snap, the speed advantage is obvious. Where a thicker wheel can feel sluggish, this one stays lively as long as you don’t torque it in the cut. The silicon carbide abrasive is well matched to masonry; it fractures sharp and keeps cutting cleanly with moderate pressure.

Cut quality and control

This wheel leaves a fairly crisp edge for an abrasive disc, especially on pavers and brick. You’ll still see some micro-chipping along the cut line—that’s the nature of dry cutting by abrasion—but you can minimize it by scoring lightly before committing to full depth. The thin kerf helps reduce spall on the exit side; if you care about the finished look, flip the piece and finish from the show side, or back the cut with scrap.

Because the wheel is thin, it’s sensitive to technique. Any twist or side load translates into chatter or a wandering kerf. Keep your wrists in line, cut with two hands, and avoid prying. If you need to curve or notch, do it with a series of shallow, straight plunges rather than trying to arc the wheel.

Wear rate and durability

Abrasive wheels are consumables, and this one is no exception. Under steady use on pavers, I could feel the diameter shrinking at a normal pace; it’s not dramatic, but it’s noticeable. Expect to go through multiple wheels for larger masonry jobs. The fiberglass reinforcement helps the wheel resist edge damage and reduces the chance of catastrophic failure, but it won’t change the fundamental wear profile. If you’re expecting diamond-wheel longevity, you’ll be disappointed. If you’re planning a day of trimming and scoring, pack extras.

The trade-off is understandable: the 0.045-inch profile is what gives the speed and crispness. Thicker abrasive wheels may last longer but cut slower and run hotter. For me, the performance is worth the consumption when I have lots of short cuts and cleanups.

Dust, heat, and safety

Dry cutting concrete creates a lot of silica dust. I used a shroud and vac and still wore a respirator—highly recommended. The wheel throws a fine, gritty plume when it’s cutting well; if you see more spark than dust on masonry, you’re pushing too hard or glazing the surface. Reduce pressure, refresh the cut with a short plunge, and let the grains re-expose.

Heat buildup was manageable. The thin kerf helps, but you can still scorch the edge if you force the cut. A light touch keeps the bond from smearing and extends wheel life. Never side-grind with this wheel; it’s designed only for straight, axial cuts. The reinforcement helps, but it’s not a license to misuse it.

Beyond concrete: cast iron and ductile iron

DeWalt lists cast iron and ductile iron among the intended materials, and I tested a short section of old cast-iron pipe. The wheel cut it effectively, producing bright sparks and a smooth kerf. It’s slower than a dedicated metal wheel on mild steel, but for cast iron it’s workable. Expect more wear than on masonry and keep the cut straight—no twisting. For frequent metal work, I’d switch to a proper metal-specific disc; for occasional pipe trims or small repairs, this wheel can bridge the gap.

Value and use cases

These come packaged in quantity, which suits jobsite realities. If you’re a landscaper, mason, or remodeler trimming the occasional block, coping pavers, or opening small chases in mortar, the performance-to-cost ratio is solid. For long, continuous cuts or big demolition, I’d step up to a diamond blade—wet if possible—for longevity and depth. But for fast, dry, on-the-grinder convenience, this wheel earns its keep.

DIY users tackling a patio or walkway will appreciate the control and speed, as long as they plan on using more than one wheel. Pros will like the way it keeps up with fast-paced layout work and detail trimming without dragging down the grinder.

Tips for best results

- Score first, then deepen the cut in two or three passes.

- Keep pressure moderate; let the wheel feed itself.

- Support the work to prevent binding on the kerf.

- Finish from the show side to minimize edge spall.

- Use a dust shroud and respirator; dry cutting masonry is dusty business.

- Don’t use the side of the wheel; it’s a cut-off disc, not a grinder.

Pros and cons

Pros:

- Fast, aggressive cuts thanks to a 0.045-inch kerf

- Predictable performance on concrete, brick, and block

- Reinforced for better stability and reduced breakage risk

- Packs in quantity for real-world job use

- Capable on cast iron in a pinch

Cons:

- Wears faster than diamond alternatives and thicker wheels

- Sensitive to side load; improper technique can cause chatter or wander

- Dry cutting produces significant dust; requires proper control and PPE

Final take

This DeWalt concrete cutting wheel hits a useful sweet spot: compact, quick, and controlled for the kind of masonry work an angle grinder excels at. It won’t replace a diamond blade for deep or continuous cuts, and you should expect to consume multiple discs on a substantial job. But if you value speed, a clean kerf, and the convenience of a thin, reinforced abrasive that’s optimized for masonry, it performs exactly as I’d want.

Recommendation: I recommend this wheel for anyone doing short to medium masonry cuts where mobility and speed matter—pavers, brick, block, and occasional cast-iron pipe trims. It’s a strong performer with the right technique and a sensible value in a multi-pack. If you’re planning heavy, continuous cutting or want maximum lifespan per disc, go diamond; for everything else, this is a dependable, job-ready choice.

Project Ideas

Business

On-Site Paver Shaping Service

Offer a mobile service to cut curves, arcs, and custom fits in concrete, brick, and block for landscapers and homeowners. The thin wheel speeds production on edge details and borders without hauling materials off-site.

Dust-Controlled Score-and-Snap

Bundle an angle grinder with a shroud and HEPA vac to provide clean scoring of masonry veneer, trim bricks, and block facings. Rapid, precise kerfs enable clean snaps and tight finish work for remodelers.

Control Joint Retrofits

Specialize in cutting narrow kerf control joints in garage floors, patios, and walkways to mitigate cracking and improve drainage. The 4-1/2 in wheel is ideal for fast, narrow scoring in thin slabs and overlays.

Cast/Ductile Iron Trim and Fit

Provide a niche service to cut and fit cast iron and ductile iron components—old pipe stubs, grates, cleanout caps, and radiators—during renovations where quick material removal and portability matter.

Artisanal Concrete Decor Line

Produce and sell geometric planters, pierced lanterns, and address stones made with precision cuts. Market through local boutiques, pop-ups, and online platforms, offering custom patterns monogrammed per order.

Creative

Faceted Concrete Planters

Cast simple cylindrical planters, then use the thin, aggressive wheel to cut crisp facets and chamfers for a gem-like look. The silicon carbide grains handle the concrete cleanly, while the wheel’s 0.045 in profile lets you sculpt fine angles and textures.

Pierced Block Lanterns

Turn hollow concrete or aircrete blocks into outdoor lanterns by cutting patterned perforations and slot windows. Add LED candles inside to project intricate light patterns across patios and paths.

Mosaic Stepping Stones

Score and cut curved channels and recesses into concrete pavers to inlay tile or colored glass. The fiberglass-reinforced wheel gives controlled, low-chatter cuts for smooth mosaic borders and letterforms.

Custom Address Paver

Create a house number plaque from a concrete or brick slab by cutting shallow grooves for numerals and edging, then paint-fill the kerfs for a high-contrast, durable sign.

Vent-Pattern Fire Ring

Build a compact fire pit using stacked concrete blocks or pavers and cut repeating vent slots and decorative motifs around the base to improve airflow and give a bespoke aesthetic.