Features

- X-LOCK attachment system for quick wheel changes

- Intended for masonry cutting and light grinding tasks

- Designed for use with small angle grinders

Specifications

| Diameter | 4-1/2 in (115 mm) |

| Thickness | 1/16 in (0.0625 in, 1.6 mm) |

| Arbor | X-LOCK (0.875 in bore) |

| Wheel Type | Type 1A (ISO 41) |

| Grit | 24 (masonry) |

| Pack Quantity | 1 |

Related Tools

Related Articles

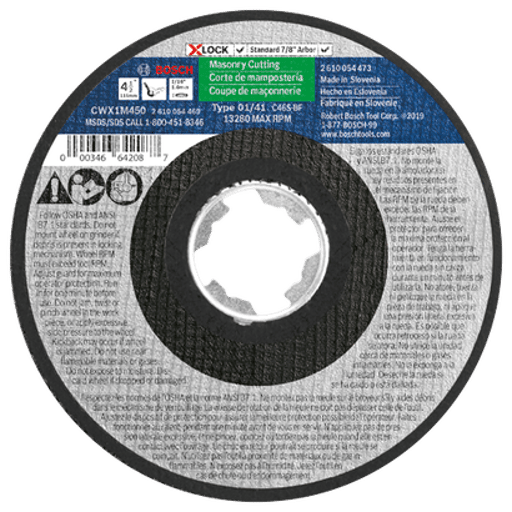

A Type 1A (ISO 41) X-LOCK abrasive wheel sized for small angle grinders. This variant is 4-1/2 in diameter with a 1/16 in thickness and is intended for masonry cutting. It uses the X-LOCK quick-change arbor interface for mounting to compatible grinders.

Bosch X-LOCK small angle grinder wheel (Type 1A / ISO 41) Review

Why I reached for this wheel

On a recent punch list, I had a mix of small masonry cuts: trimming a few concrete pavers to fit a stair tread, notching a brick for a downspout bracket, and cleaning up a couple of ragged mortar joints. I grabbed the Bosch X-LOCK masonry wheel because I wanted a thin kerf, fast material removal, and the convenience of swapping wheels without a spanner wrench. Over a few days of use, it became a telling example of where abrasive cut-off wheels still make a lot of sense in the age of diamond blades—and where they don’t.

What it is

This is a 4-1/2 in, Type 1A (ISO 41) cut-off wheel made for masonry. It’s 1/16 in (1.6 mm) thick with a coarse 24 grit that’s tuned for concrete, brick, and stone. The arbor is Bosch’s X-LOCK interface (with a 7/8 in bore profile) designed to snap on and off compatible small angle grinders without a flange nut. Pack quantity is one; if you’re doing a full day of cutting, plan accordingly.

In short: thin, aggressive, and built for quick, straight cuts in masonry with minimal fuss during changeovers.

Setup and compatibility

Mounting is as simple as aligning the wheel to the X-LOCK interface and pressing it until it clicks. Removal is one lever pull. The no-tool swap is genuinely faster, especially with gloves on or when switching between a cut-off wheel and a flap disc multiple times in a task. There’s also less fiddling with flange orientation and less chance of pinching the wheel during reassembly.

A few practical notes from my use:

- This wheel is for X-LOCK grinders. Standard 7/8 in arbor grinders can accept many accessories, but this specific interface is intended for X-LOCK only.

- Use a proper Type 1 cut-off guard. Thin cut-off wheels aren’t designed for heavy side loading.

- The wheel arrives in a simple sleeve. It’s fine, but I keep it in a rigid bin so the edge doesn’t get nicked in the tool bag.

Cutting performance

On concrete pavers and red brick, the wheel tracks straight, bites quickly, and leaves a narrow kerf that’s easy to control. The 1/16 in thickness is a sweet spot for speed versus control: thin enough to cut fast and reduce heat buildup, yet not so flimsy that it wanders when the aggregate gets coarse. The 24 grit specification shows its intent—this isn’t a finishing wheel; it’s about fast, gritty progress through mineral material.

Here’s how it handled common tasks:

- Concrete pavers: Scoring and then completing the cut produced clean edges with less spalling than a thicker wheel. I’d often score from one face, flip, and finish to keep edge blowout to a minimum.

- Brick notches: The thin kerf made it easy to sneak up on a tight clearance. Short “stab” cuts felt predictable without excessive kick.

- Mortar cleanup: It will do quick touch-ups, but keep the angle shallow and pressure light; this is still a cut-off wheel, not a grinding wheel.

The wheel runs smoothly without the “chatter” some ultra-thin discs develop as they wear down. It doesn’t load up on cured mortar or block. If you’re encountering very hard aggregate or rebar-adjacent material, it will slow, as all abrasives do, but it stays consistent rather than glazing.

Ergonomics and control

The biggest advantage is the feel of a thin profile in masonry: you can see your line, the cut establishes quickly, and you can feather the throttle to avoid overcutting a notch. Because the wheel is thin, it’s more sensitive to side pressure; a light touch and letting the wheel do the work is the right approach. I found it easiest to start with a shallow scoring pass and then deepen it rather than driving full depth immediately.

Balance on the grinder is solid. The X-LOCK interface keeps the wheel concentric, and I didn’t have any vibration spikes after repeated swaps. Tracking accuracy stayed good as the wheel diameter reduced.

Durability and wear

Abrasive wheels are consumables; life depends heavily on material density, cut length, and user pressure. With a reasonable feed rate and periodic scoring passes, wear is predictable and even. I’d characterize the life as typical for a quality 1/16 in masonry cut-off wheel—good for a handful of paver cuts, several brick notches, and odds-and-ends before you’re down to a smaller diameter that’s less useful for deeper work.

A few tips that helped maximize life:

- Make a score line first. It reduces wandering and heat.

- Avoid binding. If you feel a pinch, back out and widen the cut slightly.

- Don’t side-grind. That will eat a thin disc quickly and risks failure.

- Let the wheel cool between long cuts. Heat accelerates wear and can glaze the bond.

If you’re doing continuous, deep cuts in hard concrete all day, a diamond blade is still more economical. For small to medium cuts or mixed-task days, the speed and control here are compelling.

Safety and dust management

Silica dust is the real hazard with masonry work. I ran the grinder with a shroud hooked to a vac and wore a P100 respirator; both are worth the setup time. Cutting outdoors and staying upwind helps, but active dust collection is a better solution. Also note:

- Use the correct guard and keep it adjusted to deflect sparks and grit.

- Keep both hands on the grinder; thin wheels can grab if the kerf closes.

- Don’t use water with this abrasive wheel. Keep it dry.

Noise and vibration are in the expected range for a 4-1/2 in cut-off setup. Hearing protection is still a must.

Where this wheel shines

- Quick, precise masonry cuts where a thin kerf matters

- On-the-fly wheel changes without hunting for a spanner

- Mixed tasks that benefit from swapping between cutting and other attachments frequently

- Tight clearances and notches where a bulky diamond blade feels cumbersome

Where I’d choose something else

- Long, continuous cuts in hard concrete or block: a segmented diamond blade is faster and more cost-effective over time

- Heavy side-loading or grinding: use a wheel intended for grinding, not a Type 1A cut-off disc

- Non–X-LOCK grinders: this wheel is designed for X-LOCK; choose a standard 7/8 in arbor alternative if you don’t own a compatible grinder

Value and practicality

There’s a convenience premium baked into the X-LOCK ecosystem, but the time saved and reduced hassle add up in real use. If your workflow involves frequent changeovers, this wheel makes sense. Pack quantity is one, and given that masonry abrasive wheels are consumables, I keep a couple spares on hand. Storage matters: the edge can chip if tossed loose into a bag; a small organizer or sleeve preserves the circumference.

Quirks and small wishes

- The protective sleeve is minimal. I’d like a stiffer retail pack to better protect the rim until it’s on the grinder.

- Clear, durable labeling on the face is helpful when you’re grabbing from a bin. This one is readable, but grit and water can fade ink over time—minor, but noticeable in the field.

- A kerf marker printed near the edge would be a nice touch for layout alignment (a niche request, but handy).

None of these are deal-breakers; they’re the kind of refinements that improve day-to-day use.

Recommendation

I recommend this X-LOCK masonry wheel for anyone already invested in an X-LOCK grinder who needs a fast, thin cut-off option for brick, pavers, and light concrete work. It mounts securely in seconds, tracks straight, and cuts with the speed you expect from a 1/16 in, 24-grit disc. It’s not a replacement for a diamond blade on long, deep cuts, and it won’t tolerate side-grinding abuse, but that’s true of this class of wheel in general. As a practical, quick-change consumable for precise masonry cuts, it earns a spot in the kit—and a couple spares in the organizer.

Project Ideas

Business

Mobile Tile & Masonry Trimming

Offer on-site cutting for homeowners and contractors: resizing tiles, notching bricks, trimming stone thresholds, and cutting expansion joints. The X-LOCK quick-change system speeds setup and turnaround.

Custom Stone Address Plaques

Produce made-to-order slate/stone number plaques with kerf-cut lettering and clean edges. Sell via local boutiques, Etsy, and real estate partners; upsell mounting hardware and color inlays.

Paver Shaping for Landscapers

Provide same-day paver curve cuts, drain slots, and odd-angle fits for patios and walkways. Partner with landscape crews for per-project pricing and rapid, clean cuts on-site.

Dust-Controlled Scoring & Chasing

Specialize in shallow chase cuts and score lines in masonry for electricians/plumbers and remodelers, using vacuum shrouds and wet methods to minimize dust in occupied spaces.

Stone Coasters & Lanterns Retail Line

Manufacture small-format stone coasters, trivets, and cut-pattern lanterns for craft fairs and local shops. Batch cutting with quick wheel swaps reduces production time and boosts margins.

Creative

Mosaic Stepping Stones

Cut reclaimed ceramic or stone tiles into clean shapes and borders, then set them into concrete pavers to create custom mosaic stepping stones. Use shallow scoring for intricate patterns and quick edge trims for round or square formats.

Concrete Lantern with Cut Patterns

Cut geometric apertures into concrete pavers or precast slabs, then assemble into a cube or prism lantern around an LED candle. The 1/16 in wheel makes crisp, narrow slots that cast sharp light patterns.

Slate House-Number Plaque

Trim a slate or stone tile to size and kerf-cut the house numbers in multiple shallow passes. Paint-fill the cuts for contrast and mount with metal standoffs for a modern, durable address plaque.

Modern Concrete Planters

Cast small planters, then add clean drainage slots and decorative kerf lines with precise plunge cuts. Optionally inlay thin tile bands by cutting shallow channels for a premium look.

Saw-Cut Cement Board Art

Score patterns, line art, or typography into fiber-cement panels or thin concrete sheets. Stain or paint-wash the surface so the narrow kerfs pop, creating durable indoor/outdoor wall art.