Features

- Precision laser-cut body slots to dissipate heat

- Dark speedcoat to reduce friction

- TCG (triple-chip grind) tooth design for clean, accurate cuts

- Micrograin carbide tips for wear resistance and edge retention

- Designed for dry cutting metal

Specifications

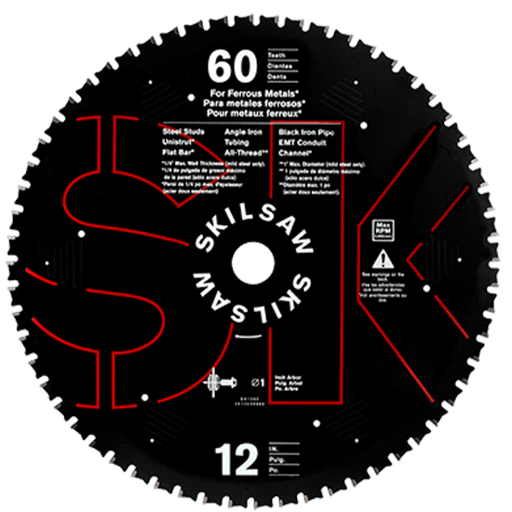

| Blade Diameter | 12 in. |

| Teeth | 60 |

| Arbor | 1 in. |

| Kerf | 0.094 in. (2.4 mm) |

| Cut Type | Dry cut metal |

| Compatible With | SPT62MTC and most major brands |

Related Tools

Related Articles

12-inch circular saw blade with 60 teeth intended for dry cutting metal. The blade body has laser-cut slots to help dissipate heat and a dark speedcoat that reduces friction. Teeth are micrograin carbide with a triple-chip grind (TCG) to provide a consistent, accurate cut and improved edge life.

Project Ideas

Business

Precut Metal Kit Products

Design and sell flat-pack kits (planters, firewood racks, garage shelves, bike stands) using angle, tube, and sheet. The blade’s fast, accurate dry cuts shorten production time and reduce finishing, letting you offer deburred, bolt-together kits shipped compactly.

Custom Aluminum Letters & Signage

Offer made-to-order letters, numbers, and simple logos from aluminum sheet and extrusion frames. Triple-chip grind teeth deliver clean edges that need minimal sanding before paint or vinyl application, enabling quick turnaround for retail, events, and storefronts.

Mobile On-Site Metal Trim Service

Provide on-site cutting of steel and aluminum components (handrails, strut channel, track, thresholds) for contractors and facility managers. Dry cutting generates less heat and fewer sparks than abrasives, allowing safer, cleaner work in finished spaces with premium per-cut pricing.

Van/RV Upfit Components

Produce precision-cut brackets, L-track mounts, cabinet frames, and solar panel rails from aluminum angle and 80/20 profiles. The blade’s consistent kerf and edge quality keep assemblies square, reducing rework and improving fit and finish for the adventure van market.

Intro to Dry-Cut Metalworking Workshops

Run weekend classes where students build a small project (wall art, planter, tool rack) while learning dry-cut techniques, deburring, and finishing. Monetize through tuition, material kits, and upselling finished add-ons or custom-cut components.

Creative

Layered Cityscape Wall Art

Cut skyline silhouettes from thin steel or aluminum sheet, then layer them with standoffs for depth and shadow. The blade’s triple-chip grind gives crisp, burr-minimized edges that need minimal sanding before paint or patina, letting you mix finishes (blackened steel, brushed aluminum) for a striking multi-layer display.

Geometric Tube Pendant Lights

Miter-cut thin-wall square or rectangular steel tubing into precise facets to form polygonal light shades. The 60T dry-cut blade produces clean, cool cuts that fit tightly for quick tack-welding or brazing. Add a matte powder coat and cloth cord for modern industrial pendants.

Modular Planter Boxes & Trellises

Build bolt-together planters and trellis frames from angle iron and flat bar. The accurate, low-burr cuts help parts align squarely so you can use rivnuts and stainless hardware instead of welding. Finish with weathering steel look or outdoor enamel for a premium garden set.

Metal Inlay Serving Boards

Cut aluminum or brass strips to inlay into routed channels in hardwood serving boards. The blade’s precise kerf produces consistent strip widths, reducing hand fitting. Epoxy fill, sand flush, and polish for a high-contrast, food-safe presentation piece.

Kinetic Garden Wind Spinner

Cut concentric aluminum rings and curved fins from sheet, then assemble on a central shaft with bearings. The clean dry cuts keep edges true so the spinner balances easily and catches light as it turns. Anodize or powder coat for weather resistance.