Features

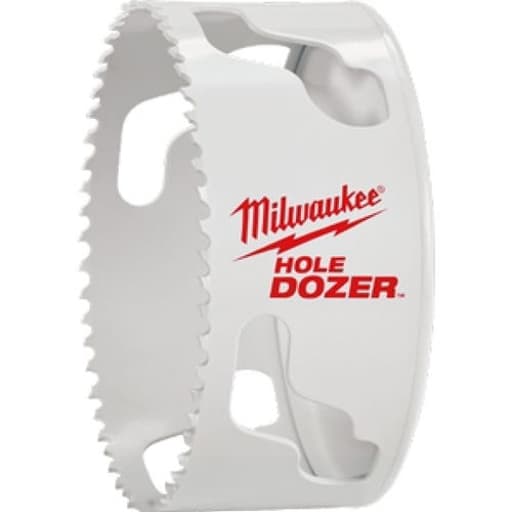

- Durable hole saw for general purpose applications.

- 3.5 TPI tooth design.

- Slots for easier plug removal.

- Increased pilot visibility for accurate placement.

- Coating to reduce friction and improve cutting efficiency.

- Made in the USA.

Specifications

| Bit Type | Hole Saw |

| Minimum Chuck Size Required | 3/8 in |

| Hole Saw Material | Bi-Metal |

| Hole Saw Diameter (In) | 3-7/8 in |

| Kit | No |

| Recommended Safety Equipment | Safety Glasses |

| Case Included | No |

| Length | 1.9 Inches |

| Hole Saw Type | Multipurpose |

| Pilot Bit Diameter (In) | 0 |

| Package Contents | (1) Hole Saw |

| Drilling Depth (In) | 1.625 |

| Opt Sku | 49-56-9644 |

| Mpn | 49-56-0207 |

| Upc/Gtin | 045242222636 |

| Product Type | Bi-Metal Hole Saws |

| Google Category | Hardware > Tool Accessories > Drill & Screwdriver Accessories > Hole Saws |

| Condition | New |

| Weight | 1.00 |

Related Tools

Related Articles

The Hole Dozer Bi-Metal Hole Saw features a tooth design that provides longevity in metal applications. It is designed for general purpose use and includes features that aid in plug removal and enhance visibility for accurate placement. The coating allows for reduced friction and improved cutting performance, making it suitable for various materials.

Milwaukee Hole Dozer Bi-Metal Hole Saw Review

The Milwaukee Hole Dozer Bi-Metal Hole Saw is a tool that caught my attention due to its reputation for durability and efficiency. As someone who frequently works with various materials, from wood to metal, I was eager to put this tool to the test across different applications. The model I used was the 49-56-9644, which boasts a 3.5 TPI tooth design and several features aimed at enhancing user experience, such as slots for easier plug removal and increased pilot visibility.

Right out of the box, the Hole Dozer feels substantial and well-made. The bi-metal construction suggests it's built to last, which is reassuring when you're about to cut into expensive materials. My first project with the Hole Dozer involved installing a soap dispenser in a walnut butcher block kitchen island with an undermount stainless steel sink. Precision was paramount here, as a mistake would mean an unsightly hole in a prominent piece of furniture.

After measuring multiple times and ensuring I had the exact size needed, I proceeded to cut. The Hole Dozer performed admirably, making a very clean hole through the walnut. When it came time to penetrate the stainless steel sink, I was impressed by how effortlessly the saw bit handled the metal. There was no noticeable struggle or signs of wear on the teeth, even after cutting through such a tough material.

However, my experience wasn't entirely without hiccups. On another occasion, I tried to cut a hole in an 18-gauge metal sink, expecting the same smooth performance. Unfortunately, this time the Hole Dozer struggled significantly, barely scratching the surface despite using cutting oil. This was disappointing, especially since the product is marketed as suitable for metal applications. I contacted Milwaukee for support, and while they were responsive, it did make me question the consistency of the tool's performance.

Switching gears, I used the Hole Dozer again for a project involving 1/4" thick steel pipes. Here, the tool shined brilliantly, cutting through the steel like it was frozen butter. The efficiency and sharpness of the teeth were remarkable, even after multiple holes. The hardest part was drilling the pilot hole; once that was done, the hole saw made quick work of the steel with minimal force required.

One of the thoughtful design elements of the Hole Dozer is the slots for plug removal. In previous hole saws I've used, it was always a tedious task to clear out the drilled material. The slots on the Hole Dozer made this process significantly easier, saving a lot of time and frustration. The increased pilot visibility also proved beneficial, particularly in projects requiring high precision.

For a DIY project, I used the Hole Dozer to make a rack for cleaning wine bottles out of a plastic cutting board. The saw managed to cut slowly and evenly through the tough plastic, which was a relief. The teeth did require cleaning halfway through each cut, but the result was clean and precise holes, making the job much easier.

It's worth noting that the Hole Dozer does seem to struggle with thicker wood on occasion. While drilling through a 2x6 pine board, the saw seemed to struggle a bit more than expected. It required a corded drill to get through, as my 20v cordless drill couldn't handle the task, even with a full charge. This experience made me cautious about recommending the Hole Dozer for thicker wood applications unless paired with a powerful drill.

In another instance, I needed to create holes for a reverse osmosis system in a kitchen sink. The Hole Dozer made this task straightforward, producing a perfect hole quickly and efficiently. This solidified my confidence in its ability to handle common household projects without much hassle.

One of the more impressive feats I achieved with the Hole Dozer was cutting through a 55-gallon steel drum. The saw made light work of the steel, drilling seven holes in about four minutes. The slugs fell into the barrel without requiring any cleanout, which was a pleasant surprise and a testament to the tool's efficiency.

Despite some mixed results, I have to commend the Hole Dozer for its overall performance. It handled a variety of materials, from thick steel to dense wood, and delivered clean, accurate holes in most cases. The build quality and thoughtful design features like the slot for plug removal and increased pilot visibility enhance the user experience significantly.

Would I recommend the Milwaukee Hole Dozer Bi-Metal Hole Saw? For the most part, yes. It excels in metal applications, particularly thicker steel, and offers a reliable solution for household projects involving materials like plastic and wood. However, if your primary use is cutting metal, be aware of its occasional inconsistency and have a backup plan just in case. Overall, the Hole Dozer is a valuable addition to any toolbox, offering durability and efficiency for a wide range of applications.

Project Ideas

Business

Custom Signage

Offer custom signage services by cutting out letters and shapes from wood or metal using the hole saw. These signs can be used for businesses, home decor, or special events.

Furniture Design

Create unique furniture pieces like tables or stools by incorporating circular cutouts in the design. Market these pieces as custom, handcrafted furniture for homes and offices.

Event Decor

Provide event decoration services by creating custom cutouts and displays for weddings, parties, and corporate events. Use the hole saw to design intricate pieces that enhance the event's theme.

Home Improvement Services

Offer home improvement services that include installing custom shelving, light fixtures, and other elements that require precise circular cutouts. Market your services to homeowners looking to renovate or update their spaces.

Art and Craft Workshops

Host workshops where participants can create their own art and craft projects using the hole saw. Provide materials and guidance, and charge a fee for the workshop. This can be a great way to engage with the local community and promote your craftsmanship.

Creative

Custom Wall Art

Use the hole saw to cut various sizes of circles from wood, metal, or acrylic sheets. Arrange these circles in a pattern to create unique wall art pieces that can be painted or stained to match home decor.

Circular Shelves

Create small circular shelves by cutting holes in wooden boards and attaching them to the wall. These can be used to display small plants, figurines, or other decorative items.

DIY Clock

Cut a large circle out of a wooden plank and drill a hole in the center for the clock mechanism. Decorate the face with numbers or designs, and add clock hands to create a custom wall clock.

Hanging Planters

Cut circular holes in the bottom of metal or wooden containers to create hanging planters. These can be hung using ropes or chains and used to display small plants indoors or outdoors.

Birdhouse Entrances

Use the hole saw to cut perfect circular entrances for DIY birdhouses. Customize the birdhouses with paint and other decorative elements to attract various bird species.