Features

- HIGH QUALITY MATERIAL: Deck Railing Bracket is made of high strength ADC-12 Aluminum alloy cast as a whole, high temperature powder coating on the surface, durable corrosion resistance, waterproof, rust-proof, Suitable for connection and installation of outdoor Deck Wood Railing and Fence

- QUALITY ASSURANCE: The Deck Railing Connector is made of high strength Aluminum alloy, Which is three times denser than ordinary plastic. Compared with ordinary plastic, ABS, PP nylon and other materials that are easily deformed and brittle to break, our Deck Railing Brackets is the most valuable choice in terms of corrosion resistance, safety and durability of use

- SIZE/QUANTITY: (LxWxH)2" x 4" x 1/16" (Actual installation Size: 1.5"x3.5"in), Qty: 20 pcs

- EASY INSTALL: 1. Snap the Deck Railing Bracket into the top of the horizontal handrail, drill pilot holes with hand drills and lock in place with screws (the ends of the posts may need to be sanded/trimmed due to deviations in external dimensions depending on the type and dryness of the wood); 2. Align the horizontal handrail with the pre-installed position of the post, drill pilot holes with hand drills (Drilled/30°) and lock in place with screws to complete the installation

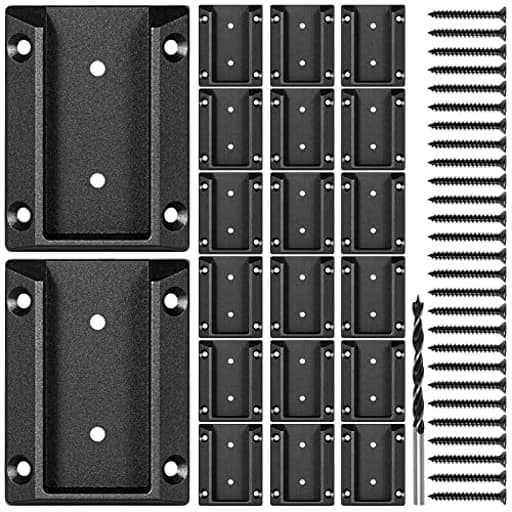

- SERVICE PROMISE: The kit comes with all accessory screws (20 pcs of Bracket Connectors, 120 Black Coated Screws, 1 1/8" Wood Drill bit). We strive to provide higher quality products and bring you a good shopping experience, if you have any questions or quality problems, feel free to contact us

Specifications

| Color | Black |

| Unit Count | 20 |

Related Tools

Set of 20 black deck railing brackets cast from ADC‑12 aluminum alloy with a high‑temperature powder‑coated finish for corrosion resistance. They connect 2"x4" (actual 1.5"x3.5") wooden railing posts to a horizontal handrail and include 120 black‑coated screws and a 1 1/8" wood drill bit for installation.

Epcee 20pcs ADC-12 Aluminum Deck Railing Bracket, Deck Railing Connectors for 2"x4" (Actually 1.5"x3.5") Wooden Deck Railing Post to Handrail Connection Review

A summer spent rebuilding my deck taught me a few truths: treated lumber moves more than you expect, alignment is everything, and the small connectors you choose matter as much as the big posts. I used Epcee’s aluminum rail brackets for tying 2x4 rails into 4x4 posts, and they ended up being one of the quiet wins of the project—clean-looking, fast to install, and far sturdier than the plastic connectors I’ve used in the past.

What you get

This is a 20-pack of cast aluminum brackets sized for standard 2x4 rails (actual 1.5 x 3.5 inches). They’re powder-coated black, consistent in finish, and free of casting flash or rough edges. In the box were color-matched screws and a pilot bit. With six screws per bracket, the kit covers a surprising amount of railing; for reference, a typical 6-foot section with top and bottom rails uses eight brackets (four per rail), so a box handles roughly five sections.

The brackets are designed for 90-degree, level connections—straight runs between posts—not stair angles. If you’re doing a staircase, you’ll need a dedicated angle bracket.

Build quality and finish

The brackets are cast from ADC-12 aluminum alloy and finished with a durable powder coat. Compared to plastic connectors, these have a noticeably more rigid, confidence-inspiring feel. Under an impact driver, they don’t chatter, flex, or crack while you’re snugging things down—an issue that crops up with plastic when temperatures drop or when lumber isn’t perfectly square.

The powder coat is well executed: even color, slight texture, and good scratch resistance. After months of sun, rain, and a couple of freeze/thaw cycles, mine still look new. The flat black blends well with black post caps and balusters and disappears visually against darker-stained rails.

Installation experience

The brackets “cup” the end of the 2x4. My process that worked well:

- Cut the rails to length with square ends.

- Push the bracket onto the rail, clamp lightly, and predrill the side holes.

- Drive the two rail-side screws, alternating left/right so the bracket stays centered.

- Bring the assembly to the post, level it, mark height, then predrill for the post screws at a slight angle.

- Drive the post-side screws, again alternating sides to keep things straight.

The fit is true to size for nominal 2x4s. On a couple of premade rail sections, the rails measured a hair under 1.5 inches thick. That left a paper-thin reveal along one face. It’s purely cosmetic and only obvious if you go hunting for it, but worth noting if your lumber is undersized or planed.

Tolerance-wise, the brackets are consistent. I didn’t have to file or tweak any to get clean fitment. If your rail ends are out of square or swollen, a few swipes with a block plane can help get a flush seat.

About the screws

The kit includes black-coated Phillips screws. They match nicely and they do work, but they were the weakest link in my install. In denser southern yellow pine, I snapped a couple of heads even with properly sized pilot holes. The finish also scuffs if your bit cams out. After the second snapped screw, I switched to my own exterior-grade, ceramic-coated Torx fasteners and the rest of the install went faster and cleaner.

Two tips if you stick with the included hardware:

- Pre-drill to a proper pilot size for the full length of the screw, not just a starter hole.

- Drive at medium speed and stop as soon as the bracket seats; don’t rely on the screw to pull a misaligned rail into position.

I’d love to see Torx screws included in a future version. They’re harder to strip, easier to control with an impact driver, and better suited to repetitive deck work.

Performance and durability

Once installed, these brackets hold rails rock-solid. I did a few unscientific “grab the rail and reef on it” tests—what a kid or an adult might do instinctively—and the joints felt rigid and quiet with no creaking, no visible deflection at the bracket, and no paint transfer or scuff at the edges.

Over a full season outdoors, the powder coat has resisted UV fading and chipping, and the aluminum hasn’t shown any sign of corrosion. That’s an advantage aluminum has over painted steel brackets: even if the coating is compromised, you’re not inviting rust. If you live in a coastal environment, aluminum plus a quality coating is a smart choice; just be mindful of fastener selection to avoid galvanic issues.

Fit and compatibility

- Rail size: Designed for standard construction 2x4s (actual 1.5 x 3.5 inches). Expect a slight gap if your rails are under-spec.

- Post size: Works on 4x4 posts (actual 3.5 inches). The bracket footprint sits nicely without overhang.

- Orientation: Flat, 90-degree connections for level runs only.

- Quantity: A 20-pack is the right bundle for medium projects or for matching top and bottom rails across several bays.

One small wishlist item would be a paper template in the box for consistent layout and screw placement, especially if you’re dialing in code-compliant rail heights across a long run.

Compared to plastic connectors

Plastic connectors from big-box stores are inexpensive and quick, but they can squeak, deform, or crack at the corners after seasonal movement. They also tend to look chalky after a couple of summers. The Epcee brackets feel meaningfully sturdier, and the powder coat holds up better aesthetically. They also add a bit of perceived quality to the finished rail—subtle, but noticeable when you’re up close.

If you’re replacing failed plastic hardware or building new in a climate that sees big temperature swings, aluminum is the safer long-term bet.

What I’d change

- Fasteners: Swap the Phillips screws for Torx or square-drive exterior screws with a tougher coating. It would reduce cam-out, speed installation, and avoid sheared heads.

- Stair solution: Offer a matching angled bracket for stair rails to keep the look consistent across an entire project.

- Instructions: Clarify pilot sizes, include a quick height chart for common rail codes, and add a simple layout template.

None of these are deal-breakers, but they’d elevate an already solid kit.

Practical tips

- Pre-finish your rails before mounting; it’s easier to get clean lines when the bracket isn’t in the way.

- Dry-fit each rail with the bracket before drilling to make sure your cuts are square and your reveal is even.

- If you switch to your own screws, go with an exterior-rated Torx in the #9–#10 range and predrill accordingly.

- Alternate driver strokes from side to side whenever tightening a bracket; it helps keep the rail centered and the bracket square.

The bottom line

The Epcee aluminum rail brackets are a smart, durable alternative to the plastic connectors that dominate the aisle. The casting quality is good, the powder coat looks sharp and has held up to weather, and the brackets themselves make for a clean, rigid connection that inspires confidence. The included screws get the job done in softer stock, but I had better results—and a quicker install—using my own exterior Torx fasteners.

Recommendation: I recommend these brackets. They offer real-world gains in strength and longevity over plastic options, the finish integrates nicely with modern deck hardware, and the 20-pack makes sense for most projects. Swap the screws for better fasteners and you’ve got a reliable, good-looking solution for tying 2x4 rails to posts that should stay solid for years.

Project Ideas

Business

Pre-cut Railing Module Kits

Create and sell DIY railing kits that include pre-cut 2x4s, a set of these ADC-12 brackets, screws, and a step-by-step guide or jig for drilling pilot holes. Market to homeowners who want a fast, attractive railing upgrade without custom carpentry—offer standard sizes and add-on planter or light kits.

Rapid Railing Upgrade Service

Offer a local installation service specializing in quick handrail and post replacements using the bracket system to reduce labor time. Pitch same-day safety upgrades for rental properties, Airbnb hosts, and elderly clients who need code-compliant rails fast; bundle a short warranty on fittings and workmanship.

Upcycled Outdoor Furniture Line

Design a line of benches, picnic tables, and planter benches using inexpensive reclaimed 2x4s joined with the aluminum brackets, then finish and sell at farmers markets or online. Emphasize durability (metal connectors vs plastic), weather resistance, and a modular look—offer custom stain or engraving options.

Workshops + Kit Sales

Run weekend workshops teaching participants to build railing panels, trellises, and small furniture using the bracket system; include a take-home kit (brackets, screws, bit) so attendees can replicate projects. Use workshops to create repeat customers and upsell pre-cut kits and video tutorials.

E‑commerce Bundle & Content Strategy

Launch an online store or Amazon listing that bundles the 20‑pack brackets with a digital installation guide, video walkthroughs, and optional pre-measured wood packages. Use how-to videos and before/after galleries to drive conversions and offer white‑label or bulk bundles to contractors.

Creative

Modular Floating Shelves

Use the ADC-12 brackets to fasten short 2x4 posts to the underside of thick planks to create floating shelf modules that bolt together edge-to-edge. The powder-coated aluminum brackets give a slim, hidden-connector look and the included screws/drill bit make quick work of repeatable, sturdy shelves for indoor or covered outdoor use.

Quick-Assembly Garden Trellis Panels

Build a series of 2'x6' trellis panels from 2x4 rails and vertical slats using the brackets at each joint so panels snap together and can be disassembled for storage. The corrosion-resistant finish makes these ideal for training climbers and repositioning beds seasonally.

Outdoor Bar/Planter Railing

Create a narrow railing along a backyard bar or counter using 2x4 posts connected to a horizontal handrail with the brackets, and attach planter boxes beneath the rail for herbs. The cast aluminum brackets handle weather exposure and give a cohesive, professional attachment point for integrated planters and foot rails.

Pergola Infill & Decorative Rail

Add decorative low rail infill between pergola posts or between rafters using the brackets to mount horizontal members quickly. Use contrasting stain or paint on the 2x4s to create a patterned accent while relying on the durable brackets to resist outdoor conditions.

Rustic Room Divider with Shelves

Construct a freestanding room divider from vertical 2x4 posts and horizontal rails connected with the brackets, incorporating staggered shelf ledges and planter niches. The supplied screws and bit let you pre-assemble panels and then bolt them together on site for moving or reconfiguration.