Features

- Enhanced Joint Integrity: enhance the structural integrity of your projects with our galvanized framing angles; These angles not only reinforce joints for stronger, straighter corners but also adapt to various sizes and thicknesses, suitable for any challenge from light-duty jobs to hefty structural tasks

- Built to Endure: crafted from construction-grade metal, our angle brackets promise durability and strength; They're strong enough for basic framing, making them an ideal choice for structural engineers seeking longevity and robustness in their designs

- Versatile Applications: these multi-purpose framing anchors are suitable for a multitude of 90-degree connections; From framing concrete forms and building decks to constructing bed frames and fences, the reversible and flexible design meets all your DIY and professional needs efficiently

- Safe and Simple Installation: our framing angles ensure easy and safe installation; The innovative speed prong holds the anchor in the right position, while the bendable ends provide a precise fit for skewed locations without splitting wood, simplifying your nailing tasks significantly

- Storm-ready Home Fortification: specifically designed to reinforce your home against high winds and hurricanes, our framing angles offer peace of mind against extreme weather conditions, ensuring your safety and the integrity of your structure

Specifications

| Color | sliver |

| Size | 1-7/16in. X 2-1/2in |

| Unit Count | 25 |

Related Tools

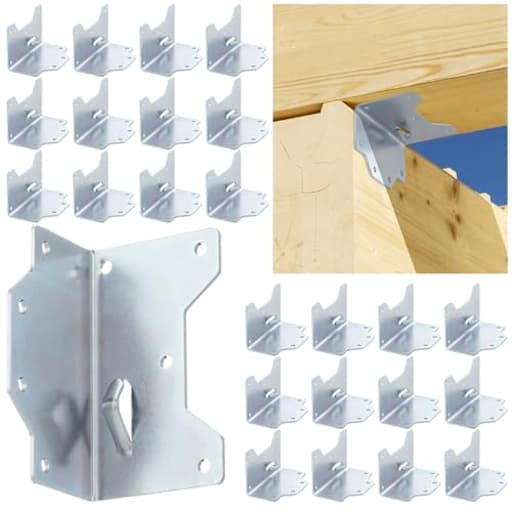

Galvanized, construction‑grade metal angle brackets for reinforcing 90° wood joints in framing, rafters, joists, decks and concrete forms. Each 1-7/16 in × 2-1/2 in bracket includes a speed prong to hold it in place and bendable ends for fitting skewed connections; 25 pieces per set.

Shimeyao 25pcs Galvanized Framing Angle Brackets - Multi Purpose Wood Frame Connectors, Rafter Deck Brackets, Joist Hanger, Concrete Forms, Reinforcing l Angle Review

Why I reached for these brackets

I’m often looking for small, reliable 90-degree connectors I can keep in a job-site bucket for quick fixes and jig building. That’s why I tried these Shimeyao angle brackets on a mixed weekend of work: stiffening a utility shelf, squaring a small shed door frame, pinning a couple of concrete forms, and securing a deck stair skirt board. A pack of 25 seemed like the right quantity for “grab-and-go” use, and the footprint—1-7/16 in by 2-1/2 in—looked handy for tight spots.

Design and build quality

These are galvanized metal angles with a reversible pattern and a neat little speed prong. The form factor is similar to the classic multi-purpose framing angle: two legs at 90 degrees, light gauge steel, multiple nail/screw holes, and bendable ends so you can tweak to a less-than-perfect corner. Out of the box, the galvanization looks even and free from obvious drips. Edges on my set were reasonably clean—no finger-slicing burrs—and none arrived bent in shipping.

The overall size is on the small side compared to some general-purpose framing angles. That’s not inherently a drawback; it just puts them into the “utility” and “light framing assist” camp rather than “primary structural connector.” In hand, the steel feels close to the lighter gauges you see on multi-use connectors. You can flex an end with pliers, as intended, but the bracket doesn’t feel flimsy. I’d avoid repeated bending in the same spot; like any light-gauge steel, it’ll fatigue if you work it back and forth.

Installation experience

The speed prong is a time saver. One tap with a hammer sets the bracket so it doesn’t slide while you reach for fasteners. I found it especially helpful working solo on an awkward shed door jamb—one hand to hold the rail, one to tap the bracket, and it stayed put while I drove screws.

Hole sizing matters here. The holes are on the small side and closer to what I’d expect for #8 screws or smaller nails. Traditional 10d hanger nails won’t fit, and even some 8d nails are a squeeze. I had the best experience with:

- #8 x 1-1/4 in exterior-rated screws for pine framing and shelving

- 6d box nails for temporary formwork

- Simpson-style SD8 or equivalent structural screws where I wanted a higher shear rating without upsizing the hole

If you try to force oversized nails, you’ll risk deforming the bracket or splitting thinner stock. Bring the right fasteners and installation becomes straightforward. I recommend an awl or a self-centering bit to mark the first hole if you’re working overhead—these are small targets.

The bendable ends are useful. I tweaked a couple of brackets a few degrees to match slightly out-of-square corners and a skewed connection between a stair skirt and a post. Make your bend once, slowly, and call it good—don’t “tune” it repeatedly.

Strength and what they’re good for

I wouldn’t classify these as a primary structural connector, and there are two reasons for that:

- Size and bearing area are modest. You’re reinforcing a joint, not building a load path.

- There’s no published code listing or load table. For anything inspected or critical (hurricane ties, seismic load paths, major deck connections), you want an ICC-ES listed connector with matching fasteners.

That said, within their lane, they’re very handy. I used them to:

- Square up a small door frame before skinning it with sheathing

- Keep a long shelf from racking side to side

- Pin 2x form boards to stakes while pouring a short slab

- Reinforce a fence gate corner that had started to twist

They’re also good for quick shop jigs and fixtures: squaring sled fences, bracing a knockdown work surface, or temporarily pinning parts while glue sets. The small footprint fits where larger brackets won’t, and the prong speeds layout.

Exterior use and corrosion

The brackets are galvanized, which is the baseline for outdoor use. The coating on my set looks like standard galvanization rather than heavy hot-dip. In practice, that means:

- They’ll hold up fine for interior use and many sheltered exterior applications.

- For wet locations, coastal environments, or contact with modern pressure-treated lumber, I prefer hot-dip galvanized or stainless connectors.

If you do use them outdoors, match with exterior-rated fasteners and avoid mixing dissimilar metals. For pressure-treated wood, choose compatible coatings on screws/nails to prevent corrosion.

Fit and finish notes

- The hole pattern gave me enough options to hit solid wood without splitting near edges. I’d still avoid placing fasteners too close to the end grain of narrow pieces.

- The prong leaves a small mark if you need to reposition; tap gently and test fit before you commit.

- The compact size hides easily behind trim, which is nice when you want to reinforce without advertising it.

What I wish were better

- Hole diameter: A slightly larger hole set would broaden fastener options. As is, you need to plan for #8 screws or 6d nails, which may not match what’s already in your apron.

- Documentation: There’s no guidance on fastener types or any load reference. Even a simple “intended fasteners: #8 screws or 6d nails; interior/exterior use” sheet would help DIYers avoid mistakes.

- Coating clarity: Stating the galvanization type and thickness would make it easier to decide where they’re appropriate outdoors, especially with treated lumber.

Who they’re for

- DIYers needing a general-purpose angle for small frames, shelves, gates, and jigs

- Pros who want a stash of compact angles for temporary bracing, layout help, and light-duty fixes

- Anyone working in tight spaces where a larger bracket won’t fit

Who should look elsewhere:

- Builders needing code-listed connectors for hurricane ties, rafter-to-plate, or deck ledger work

- Projects that demand heavy-load connectors with published values and matched fasteners

Tips for success

- Bring the right fasteners: #8 exterior screws or 6d box nails work well. Keep a handful of structural #8 screws if you want better shear capacity without reaming holes.

- Pre-bend once: Use pliers to tweak a bracket if the joint isn’t perfectly square, then leave it alone.

- Use the prong to your advantage: Tack, check alignment, then drive fasteners—especially helpful working solo.

- For treated lumber outdoors: Pair with compatible coated fasteners and consider a heavier connector in wet or coastal settings.

The bottom line

These Shimeyao angle brackets hit the mark as compact, multi-purpose connectors for light-duty reinforcement and day-to-day fixes. The speed prong is genuinely helpful, the bendable ends make real-world fits easier, and the small footprint opens up placements larger brackets can’t handle. The trade-offs are clear: holes that favor smaller fasteners, no published structural ratings, and galvanization that’s adequate but not the heavy-duty kind I’d choose for aggressive outdoor environments.

Recommendation: I recommend these for utility bracing, shop jigs, small framing assists, and quick on-site problem solving—provided you use appropriately sized screws or 6d nails and keep them out of code-critical structural roles. If you need rated connectors for high loads or inspected work, choose a branded, ICC-listed angle with specified fasteners. For everything else, a 25-piece pack like this is a practical addition to the kit.

Project Ideas

Business

Pre-cut DIY Project Kits

Sell kits (shelves, planter boxes, fold-down tables) that include pre-cut lumber, the required galvanized angle brackets, screws, and step-by-step instructions. Market to homeowners who want quick weekend builds. Kits simplify sourcing, cut waste, and allow a healthy margin on bundled hardware and instructions.

Deck and Porch Retrofit Service

Offer a targeted service to reinforce existing decks, porches, and rafters against wind and weather using galvanized angle brackets. Position as safety/hurricane retrofit for homeowners and small landlords. Low-cost materials + focused labor can scale with repeat clients and local contractor partnerships.

Custom Industrial Furniture Line

Create a line of small-batch furniture (tables, benches, shelves) that features visible galvanized brackets as a design signature. Emphasize durability and outdoor-ready finishes. Sell via Etsy, local boutiques, and Instagram; brackets become part of the brand identity and justify premium pricing.

Maker Workshops & Pop-up Classes

Host hands-on classes teaching beginner projects that rely on these brackets (floating shelf, planter, kids' fort). Charge per participant, supply materials, and sell take-home kits and extra hardware. Workshops build community, recurring revenue, and a direct sales channel for brackets and lumber.

Content + Affiliate Sales Funnel

Produce short how-to videos and downloadable plans centered on bracket-based projects. Drive traffic via social media and monetize with affiliate links to the galvanized brackets, nails/screws, and tool partners. Combine ad revenue, paid plans, and direct kit sales for diversified income.

Creative

Hidden-Reinforced Floating Shelves

Build clean, minimalist floating shelves from hardwood planks and use the angle brackets inside the corners to create a hidden, load-bearing pocket. The speed prong keeps the bracket aligned while you fasten through the shelf bottom; bend the ends for a snug fit in non-perfect cuts. Result: shelves that look frameless but hold heavy books, plants, or electronics.

Modular Stackable Planter Boxes

Make a series of identical planter boxes with galvanized brackets reinforcing each 90° corner so they stack and bolt together. The corrosion resistance is ideal for outdoor use. Design them to interlock for vertical gardens or to form raised beds — easy replacement of a single box and sturdy under wet soil conditions.

Fold-Down Wall Workbench/Table

Create a compact wall-mounted workbench that folds flat when not in use. Use the angle brackets at critical hinge corners and to reinforce the support arms; bend ends to adapt to the hinge geometry. The speed prong simplifies assembly, and the durable plating gives a rugged, industrial aesthetic.

Industrial-Accent Coffee Table

Combine reclaimed wood tops with exposed galvanized angle brackets as corner accents. Fasten brackets visibly (decorate with round-head screws) to evoke an industrial style while actually reinforcing joints. Great for upcycled furniture — brackets protect corners and add character.

Portable Kids' Fort Frame System

Design lightweight, modular frames for kids' play forts using short lumber and angle brackets as quick corner connectors. Bend bracket ends as needed for slightly off-square members; speed prongs hold pieces while you assemble. Frames can be disassembled and reconfigured into tents, tables, or tunnels.