Features

- NON-SUBMERSIBLE MEDIUM TEXTURE: Tuff Coat UT-100 series is a single component, flexible, water-based non-skid coating created through a unique process of cross-linking urethanes, acrylics, co-polymers and recycled rubber granules to create a long-lasting non-slip finish.

- Water-based, durable, flexible. This non-submersible product is designed to provide an attractive, durable, impact-resistant, non-slip surface for pool decks, ramps, locker rooms, kitchens, foot bridges, stairs and other areas requiring slip resistance that will not be submerged.

- Tuff Coat’s flexible matte finish dries to 30-35 mils of thickness creating a finish that hides significant imperfections on all surfaces as well as improves existing non-skid finishes to provide additional safety. This product is odorless and should be applied with a Tuff Coat roller or low-pressure hopper spray gun.

- Tuff Coat 100 series 1 gallon available in 19 colors.

- Excellent for concrete, fiberglass, wood, metal substrates, and previously painted surfaces.

Specifications

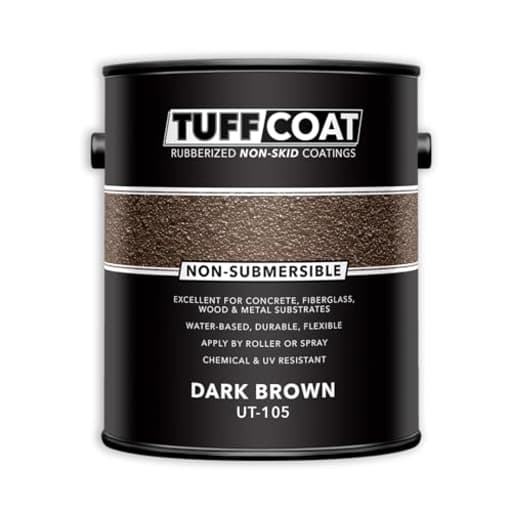

| Color | Dark Brown |

| Size | 128 Fl Oz (Pack of 1) |

| Unit Count | 1 |

Related Tools

Water-based, single-component rubberized non-skid coating with a medium texture designed to create a flexible, matte slip-resistant surface on concrete, fiberglass, wood, metal and previously painted substrates. Formulated from cross-linked urethanes, acrylics, co-polymers and recycled rubber granules, it dries to 30–35 mils, is non-submersible and odorless, and is applied with a roller or low‑pressure hopper spray. Suitable for areas requiring slip resistance such as pool decks, ramps, stairs and walkways.

Tuff Coat UT-105 Dark Brown - 1 Gallon: Medium Texture, Non-Submersible, Water-Based, Rubberized Non-Skid Coating Review

What this coating is and where it shines

I tested Tuff Coat UT-105 in Dark Brown across two small but telling projects: a pressure-treated wood ramp and a section of weathered concrete steps that were slick when wet. This is a water-based, single-component, rubberized non-skid coating with a medium texture. It’s built from cross-linked urethanes, acrylics, co-polymers, and recycled rubber granules, and it dries thick—about 30–35 mils in film build—so it adds real texture and hides a surprising amount of surface ugliness. It’s also non-submersible, so think pool decks, ramps, walkways, and stairs—not inside a pool or constant-immersion situations.

In short: if you need a matte, grippy surface that’s comfortable underfoot and more forgiving than silica-sand-in-paint solutions, this coating hits that brief.

Surface prep and primer: the make-or-break step

UT-105 is only as good as your prep, and that starts with the right primer. Different substrates require specific primers, and pairing them correctly matters for adhesion and durability. On my wood ramp, I sanded to open the grain (60–80 grit), cleaned thoroughly, and used a compatible primer per the manufacturer’s chart. On concrete, I etched, neutralized, rinsed, let it dry, and used the appropriate concrete primer.

A few practical notes:

- Stick to the recoat windows on the primer. If you’re using a two-part epoxy primer, respect the pot life. I mix smaller batches to avoid waste and panic.

- Prime to seal porosity and lock down dust; don’t skip it on bare, porous, or glossy surfaces you’ve sanded smooth. UT-105 grabs best onto a primed, uniform base.

Application: the right tools, the right technique

This coating contains rubber granules that settle fast. Plan on power mixing and frequent re-stirring:

- Use a drill with a paint paddle to bring the heavy aggregate up from the bottom. You’ll see a dense layer that can be a couple inches thick at the can’s base—get that fully suspended.

- Stir again each time you refill your tray. If you don’t, you’ll get inconsistent texture and color shift.

Tools matter here:

- Roller: A standard nap roller won’t carry the granules well. The brand’s spongy, open-cell roller loads and releases the rubber particles properly and gives a uniform texture. Expect to discard rollers at the end; cleaning them thoroughly is a chore once the product starts to set.

- Hopper gun: On larger surfaces, a low-pressure hopper gun lays down an even texture quickly. Keep pressure on the low side and do a test panel to dial in flow.

Masking tips:

- Use high-quality painter’s tape and don’t leave it on for long. Remove it while the coating is still green to avoid bonding. Always test your tape/primer combo in an inconspicuous spot.

Coats, coverage, and dry time

This isn’t like thin porch paint. To hit that 30–35 mil build, you’ll likely apply 2–4 coats, depending on how aggressive you want the texture and how rough the substrate is. I prefer a lighter first coat to establish coverage and then build to the texture I want on subsequent passes.

Coverage depends heavily on surface profile and how much texture you build. As a planning number, I’d budget conservatively—this is closer to specialty floor coatings than wall paint. If you’re coating rough concrete or you want a very grippy surface, buy extra. The finish is typically dry to the touch in warm conditions within an hour or two, but I still follow the recoat window on the label and give it a proper cure before heavy use.

Cleanup is easy while wet—water and mild detergent are enough. Once it starts to set, it gets stubborn fast, so clean tools promptly.

Finish and traction

UT-105 dries to a flexible, matte surface that does two things well:

- It adds real, usable traction (wet or dry).

- It hides flaws. Hairline cracks, patched areas, and minor gouges visually disappear under the rubberized texture.

The texture is “medium.” Barefoot comfort is good (no gritty, sandpaper feel), and it’s gentle on paws. On the ramp and steps, traction improved dramatically, and I’ve had no issues with flaking or telegraphing of previous imperfections. The Dark Brown reads as a deep, earthy matte—helpful for disguising dirt and scuffs.

Durability and maintenance

The film’s flexibility helps it shrug off minor impacts and the expansion/contraction cycles that can fracture brittle coatings. On my concrete steps, abrasion from regular foot traffic has only burnished the high spots very slightly, with no loss of traction. On the wood ramp, the coating remained intact through a few freeze-thaw cycles and plenty of wet weather.

Maintenance is straightforward:

- Routine cleaning with a stiff-bristle brush and soapy water keeps the texture from loading with grime.

- Avoid harsh solvents; this is a water-based system.

- If you need to touch up, scuff cleanly, spot-prime if required by the substrate, and recoat. Feathering in is forgiving thanks to the texture.

Where it fits best

Use UT-105 when you need a safer, non-slip surface that still looks tidy:

- Pool decks, locker rooms, and entryways where bare feet or light footwear is common

- Ramps, stairs, and platforms that get slick when wet

- Utility trailers and small platforms where a soft, rubberized texture is preferable to abrasive grit

Because it’s non-submersible, it’s not a fit for submerged steps, fountains, or hulls. For automotive or heavy vehicular traffic, I’d be cautious—slow-speed, occasional tire contact is one thing, but this isn’t a high-build bedliner.

Limitations and gotchas

A few cautions from my own process:

- Cost and coverage: This is a specialty coating. By the time you add primer, the right rollers, and multiple coats, it’s not a budget solution. If you only need minimal traction and don’t care about aesthetics or comfort, a sand-and-paint blend will be cheaper (and harsher underfoot).

- Tape sensitivity: Mask thoughtfully, test first, and pull tape early. Some tape/primer combinations can bond unexpectedly if left too long or pressed too aggressively onto fresh primer.

- Mixing discipline: If you don’t mechanically mix and re-suspend the rubber granules often, you’ll get inconsistent texture and weak traction. Hand stirring won’t cut it.

Practical tips for a smoother job

- Do a small mock-up to lock in texture and color before starting a large area.

- Work in manageable sections so you can maintain a wet edge and consistent aggregate distribution.

- Keep a damp rag and bucket handy for immediate cleanups; once this skins, removal gets difficult.

- Expect to discard rollers and trays; plan accordingly.

- Mind the weather: moderate temperatures and low humidity make life easier. Avoid direct, hot sun that can flash-dry the surface before the granules lay flat.

The bottom line

Tuff Coat UT-105 is a well-thought-out non-skid coating that delivers dependable traction and a tidy, matte, rubberized finish on concrete, wood, fiberglass, metal, and previously painted surfaces—provided you pair it with the right primer and respect the application steps. It hides blemishes better than abrasive grit systems, feels better underfoot, and cleans up with water when wet. It is not cheap, and you’ll use more per square foot than conventional paint, but you get a thicker, more resilient film and a finish that looks deliberate rather than improvised.

Recommendation: I recommend UT-105 for non-submerged areas where slip resistance and appearance both matter—pool decks, ramps, stairs, walkways, and similar spaces. Budget for primer and the proper rollers, test your masking approach, and plan your mixing and coats. If you’re on a tight budget or need a submersible or ultra-smooth finish, look elsewhere. For everyone else, this coating strikes a smart balance of safety, durability, and a clean, professional look.

Project Ideas

Business

Mobile Non‑Slip Resurfacing Service

Offer a local service targeting homeowners, landlords, and small businesses to refinish pool decks, porches, ramps, and stairs with UT-105. Market safety, low odor, color options, and quick turnaround. Equipment: roller kits and optional low‑pressure hopper spray for larger jobs. Revenue model: flat-rate small jobs, per-square-foot pricing for larger surfaces, and add-ons like color borders or stencil work.

Senior Safety & Accessibility Upgrades

Specialize in slip-resistance upgrades for elderly and mobility-impaired clients—install non-skid coatings on entryways, ramps, bathroom thresholds, and outdoor stairs. Partner with occupational therapists, senior living facilities, and home health agencies. Emphasize OSHA/ADA-friendly practices, durable traction, and aesthetics that preserve home value.

DIY Kits + Instructional Content

Create and sell branded DIY application kits that include a 1‑gallon UT-105, a Tuff Coat roller, masking supplies, and step‑by‑step instructions or access to a how‑to video. Upsell color packs and maintenance supplies. Market via social media, local hardware stores, and home improvement marketplaces—target weekend DIYers and small contractors looking for an odorless, user‑friendly non‑skid product.

Commercial Contracts for Marinas & Restaurants

Bid for recurring contracts with marinas (walkways, boat ramps not submerged), restaurants (kitchen ramps, outdoor dining decks), gyms, and schools to apply non-slip coatings on high-traffic areas. Position the service as safety compliance and liability reduction—offer scheduled maintenance packages and seasonal touch-ups to maintain traction and appearance.

Staging & Safety Package for Real Estate

Partner with real estate agents and property managers to offer a quick, affordable non-slip refresh for homes prior to listing—porches, entry steps, and back decks. Promote the upgrade as a low-cost way to improve buyer perception, reduce liability during showings, and hide surface imperfections. Price as an add-on service to home staging packages.

Creative

Textured Patio Makeover

Refinish a worn concrete or wood patio with the UT-105 to create a durable, slip-resistant outdoor living space. Use two coats with a Tuff Coat roller for consistent medium texture, choose a dark brown or other available color to match furniture, and add contrasting border stripes or inlaid stencil patterns for visual interest. Benefits: hides imperfections, low odor, flexible finish that stands up to foot traffic and outdoor elements.

Custom Non‑Slip Pool Surround Accent

Create patterned non-slip panels around a pool deck (non-submersible use only) by masking off shapes and rolling UT-105 in alternating colors. Use recycled rubber granule texture for grip and safety near wet areas. Great for residential pools, hotel courtyards, or backyard water features where submerged coating isn't needed. Finish hides blemishes and is comfortable underfoot.

Safe & Stylish Stairs

Refinish indoor or outdoor stairs (wood, concrete, metal) with the UT-105 to produce a matte, medium-textured tread that reduces slips. Add riser color contrast or custom graphics on the sides for a decorative touch. Good for porches, basement steps, workshop stairs, and multi-level decks. Application with a roller gives even texture and durable protection.

Pet-Friendly Ramps and Platforms

Build or resurface dog ramps, pet play platforms, or elderly pet steps using UT-105 to provide traction and hide rough substrate imperfections. The flexible, impact-resistant finish is gentle on paws and reduces skidding. Use colors that blend with home decor and seal edges for easy cleaning.

Upcycled Furniture & Planter Bases

Turn old wooden benches, planters, or work tables into durable, outdoor-ready pieces by coating top surfaces with UT-105 for slip resistance and weatherability. The medium texture adds a tactile industrial look and hides surface flaws. Ideal for DIY urban garden projects or rustic patio furniture makeovers.