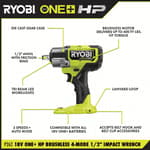

Features

- 400 ft-lbs maximum torque

- 1/2 in. drive with detent pin anvil

- Variable-speed trigger with electric brake

- LED work light with delay

- Durable magnesium gear case and all-metal transmission

- Compatible with 20V lithium-ion batteries (battery and charger sold separately)

- Brushless motor (per product data)

- Ergonomic handle for improved user comfort

Specifications

| Drive Size | 1/2 in. |

| Maximum Torque (Ft Lbs) | 400 |

| Maximum Torque (Nm) | 540 |

| No Load Speed (Rpm) | 1500 |

| Impact Rate (Ipm) | 2300 |

| Anvil Type | Detent Pin |

| Battery Voltage | 20 V |

| Battery Chemistry | Lithium Ion |

| Battery Quantity Included | 0 |

| Power Source | Cordless |

| Motor Type | Brushless |

| Has Led Light | Yes |

| Has Variable Speed Trigger | Yes |

| Is It A Set | No |

| Product Weight (Lbs) | 5.2 |

| Product Weight (Kg) | 2.5 |

| Product Length (In) | 10.9 |

| Product Height (In) | 8.8 |

| Product Width (In) | 4.0 |

| Product Length (Mm) | 276 |

| Product Height (Mm) | 222 |

| Product Width (Mm) | 102 |

| Tool Length (Mm) | 27 |

| Warranty | 3 Year Limited Warranty; 1 Year Free Service; 90 Day Satisfaction Guarantee |

| Includes | Tool only (battery and charger sold separately) |

Related Tools

Related Articles

Cordless 1/2 in. high-torque impact wrench designed for heavy fastening and removal tasks. Provides up to 400 ft-lbs of maximum torque, a variable-speed trigger with an electric brake for control, and an LED work light for visibility. It uses 20V lithium-ion batteries (sold separately) and features a durable magnesium gear case with an all-metal transmission.

DeWalt 20V MAX 1/2 in. High Torque Impact Wrench (Tool Only) Review

Why I picked up this impact

I reach for an impact wrench when cheater bars, heat, and penetrating oil start wasting time. I wanted a cordless 1/2-inch unit that could live in the truck, break loose stubborn automotive fasteners, and still be controllable enough for assembly work. This DeWalt impact wrench checked the right boxes on paper: 400 ft-lbs of max torque, a brushless motor for efficiency, a durable magnesium gear case, and the familiar 20V battery platform. After several weeks tackling suspension components, lug nuts, and a handful of larger structural bolts, here’s how it actually performs.

Power and real-world torque

Numbers don’t turn bolts—impacts do. Rated at 400 ft-lbs with 2,300 impacts per minute, this wrench sits in that “high-torque but not extreme” category. In practice, it has been absolutely capable on:

- Passenger vehicle lug nuts torqued between 90–140 ft-lbs

- Rusted sway bar end links and strut hardware

- Axle nuts on compact and midsize vehicles

- Hitch hardware and frame bolts that had seen a few salty winters

On the toughest fasteners, it sometimes needs a few seconds of hammering before the threads surrender, but it gets there. For severely corroded heavy-truck hardware or large industrial flanges, I’d step up to an ultra-high-torque class. For general automotive work, farm equipment, and construction fastening, this one reliably brings the heat.

A quick note on batteries: with a 5.0Ah pack the tool hits hard and keeps going. I tried it with a smaller, lightly charged 1.5Ah pack out of curiosity and still broke free several lug nuts and a couple of stubborn suspension fasteners—enough to get out of a bind—but runtime and peak consistency are clearly better with 4.0Ah+ packs.

Control and finesse

The variable-speed trigger is the star here. There are no preset speed modes or torque stages, so the tool lives and dies by your finger. The trigger is well-tuned: easy to creep fasteners on at low RPM without immediate hammering, and smooth to ramp up when it’s time to impact. The electric brake stops the anvil quickly, which keeps sockets from coasting off and helps prevent overrun when you’re snugging fasteners ahead of final torque.

Because there’s no “snug” or “precision” mode, you do need to be disciplined. My routine:

- Start threads by hand.

- Use the impact just to snug.

- Always finish with a torque wrench for critical fasteners.

That workflow delivers speed without sacrificing accuracy.

Ergonomics and balance

At 5.2 lbs bare and about 7 lbs with a 5Ah battery, this isn’t a compact. The handle shape is classic DeWalt—grippy, slightly palm-filling, and easy to index at awkward angles. The weight is forward-biased like most 1/2-inch impacts, but it’s manageable over a long day with reasonable breaks.

Size-wise, the head is not overly bulky for a 1/2-inch high-torque, but it’s still a handful. It gets under fenders and into wheel wells fine, yet you’ll be swapping to a compact driver for tight engine bay work. The LED work light, mounted near the trigger, casts a useful cone with a short-afterglow delay. It’s great for seeing the next fastener without re-aiming a flashlight, though, like most tool-mounted LEDs, it can shadow in deep recesses.

Anvil and socket retention

This model uses a detent pin anvil rather than a hog ring. That choice prioritizes security over speed: sockets stay put, even in positions where a hog ring might let one walk off. The trade-off is that you need to depress the pin to remove sockets, which can slow you down if you’re swapping sizes frequently with gloves on. For field work and ladder work, I prefer the detent pin; in high-turnover shop environments, some techs will prefer the faster socket changes of a hog ring anvil.

Build quality and durability

The magnesium gear case and all-metal transmission inspire confidence, and the exterior molding takes bumps well. I’ve knocked it around a trailer deck and concrete shop floor more than once without any alignment or anvil wobble issues. The brushless motor runs cool for the outputs involved, and there’s no noticeable power sag until the battery is truly on its last legs. Maintenance is basic—keep the anvil lightly oiled, don’t starve it of batteries, and store it dry.

Noise and vibration are exactly what you’d expect for a 1/2-inch impact in this torque class. It’s loud when it’s hammering. Wear hearing protection in the shop and be mindful of neighbors if you’re wrenching curbside.

Speed, impacts, and battery life

The rated 0–1,500 RPM and 2,300 IPM feel honest. On light fasteners, it transitions cleanly from spin to impact; on heavier ones, it spools quickly and hits with a consistent cadence. With a 5Ah pack, I can rotate four tires, do a brake job, and still have headroom for a few stuck fasteners. With 2–3Ah packs, runtime is noticeably shorter and the tool will throttle earlier under sustained load.

If you’re building out a kit, my practical pairing is a 5Ah primary and a compact 2Ah backup. If you plan on extended, high-load sessions (frame swaps, full suspension overhauls), two 5Ah packs keep the day flowing.

What it does well

- Breakaway torque that covers the majority of automotive and construction tasks without needing a cord or air line.

- Trigger control that makes up for the lack of preset modes.

- Detent pin anvil that keeps sockets secure when working overhead or in the field.

- LED with a helpful afterglow and an electric brake that improves safety and workflow.

- Compatibility with the 20V platform—no new chargers needed if you’re already invested.

Where it comes up short

- No speed/torque selector. Trigger-only control is fine for experienced users, but some will miss a low-power mode for delicate work.

- Bulk and weight are typical for the class but still limit access in cramped engine bays.

- Detent pin slows socket swaps. If you change sockets all day long, it adds up.

- It tops out at 400 ft-lbs. For extremely seized heavy-truck fasteners or large structural assemblies, you’ll want a bigger gun.

Use and safety tips

- Always crack fasteners loose with the impact, then finish tightening with a torque wrench for spec-critical joints (brakes, wheels, suspension).

- Use impact-rated sockets and extensions; chrome sockets don’t belong on impacts.

- A thin coat of anti-seize on the anvil keeps sockets sliding smoothly over the detent pin.

- Consider torque sticks for wheel installs if you must use the impact to snug lug nuts.

- Wear gloves and hearing protection—impacts transmit vibration and are loud under load.

Warranty and value

The warranty package (3-year limited, 1-year free service, 90-day satisfaction) is solid and typical for the brand. As a tool-only purchase, the upfront price is reasonable if you already own 20V batteries; if you don’t, budget for at least one 4–5Ah pack and a charger. That said, the flexibility to share batteries across drills, saws, and lights increases the long-term value considerably.

Final thoughts and recommendation

This DeWalt impact wrench has become my default grab for real-world wrenching: strong enough for axle nuts and rusty suspension hardware, controlled enough for assembly, and durable enough to live in a truck box. The lack of preset modes isn’t a deal-breaker given how linear the trigger is, and the detent pin anvil, while slower for socket changes, is the right call for secure retention in the field.

I recommend it to DIYers and pros who need a reliable 1/2-inch cordless impact for automotive, equipment maintenance, and structural tasks, especially if they’re already on the 20V platform. If your day-to-day involves truly seized heavy-truck fasteners or industrial bolting, you’ll want a bigger class of tool. For everyone else, this strikes a smart balance of power, control, and durability without the bulk and cost of the highest-torque monsters.

Project Ideas

Business

Mobile Tire Rotation and Lug Nut Service

Offer on-site tire rotations, seasonal wheel swaps, and stuck lug removal for commuters and fleets. Use the impact wrench for fast removal, then verify final torque with a calibrated torque wrench to manufacturer specs. Market to apartment complexes and small businesses needing minimal downtime.

Deck and Pergola Fastener Specialist

Partner with contractors to install structural hardware, ledger fasteners, and long timber screws on decks and pergolas. The wrench’s high torque and variable speed make driving big lags efficient while reducing fatigue on large jobs. Bill by the foot or by fastener installed, and provide documentation photos for builders.

Event and Trade Show Assembly Crew

Assemble and tear down aluminum staging, truss, and booth frames that rely on bolted connections. The LED light and cordless power help in low-lit venues and tight schedules. Package services as flat-rate per booth size with add-ons for transport and storage.

Farm and Ranch On-Site Repair

Provide on-farm service to replace broken gate hardware, tighten/replace machinery guards, and assemble bolt-up corrals and feeders. The impact wrench breaks free rusted fasteners and speeds installs far from outlets. Offer subscription maintenance rounds timed to planting and harvest seasons.

Industrial-Style Furniture Microbrand

Launch a small brand selling bolt-together desks, shelves, and workbenches shipped flat. The impact wrench streamlines production and QA assembly; include a simple hand tool with each kit for customers. Sell online with local delivery and optional in-home assembly upsells.

Creative

Bolt-Together Industrial Furniture Set

Design a coffee table, bookshelf, and bench that all assemble with 1/2 in. bolts and structural screws, mixing angle iron and reclaimed wood. The impact wrench lets you drive long lag screws and clamp tight connections quickly, while the LED helps align hardware in dim shop corners. Offer plans and cut lists so others can replicate your set.

Kinetic Wind Sculpture

Build a yard sculpture with rotating arms and counterweights mounted on bearings and bolted hubs. The 400 ft-lbs torque makes quick work of stubborn hardware while the variable-speed trigger gives you control seating bearings without overdriving. Use the wrench to balance, assemble, and service the piece over time.

Reclaimed Auto Parts Garden Bench

Repurpose brake rotors, wheels, and leaf springs into a stout outdoor bench by bolting components to a simple frame. The impact wrench’s detent pin anvil keeps sockets secure when working at odd angles, and the brushless motor delivers the power to break loose rusted fasteners. Finish with a clear coat to showcase the patina.

Modular Home Gym Power Rack

Fabricate a bolt-together power rack from drilled 2x3 steel tube and 5/8 in. grade-8 hardware so it can be flat-packed and reconfigured. Use the wrench to assemble uprights, crossmembers, and J-cups quickly; then final-torque critical joints with a torque wrench. Add accessories like spotter arms and plate storage using the same bolted system.

Overland Roof Rack and Accessory System

Create a modular, bolt-on roof rack with interchangeable mounts for shovels, jacks, and light bars. The cordless impact wrench speeds installing rivnuts, brackets, and high-strength fasteners without a corded setup, and the LED helps during dusk installs. Sell templates for common vehicles and accessory kits.