Features

- 12 A electronic variable-speed motor (8,000–24,000 rpm)

- Soft-start to reduce start-up torque

- Full feedback control for constant speed under load

- Dust-sealed switch

- Spindle lock for single-wrench bit changes

- Flat top for easier bit and depth changes

- Micro-fine depth adjustment (1/64 in increments)

- Quick-release motor latches for motor removal

- Detachable cordset for serviceability

- Clear LEXAN sub-base for visibility and template guide compatibility

- Rubber overmold handles for grip and balance

- Heavy-duty die-cast aluminum base and motor housing

- Nickel-plated motor housing to aid smooth depth adjustment

- Self-releasing, multi-slot collets to reduce frozen bits

Specifications

| Power Source | Corded |

| Amperage | 12 A |

| Horsepower (Maximum) | 2.25 hp |

| No Load Speed (Variable) | 8,000–24,000 rpm |

| Maximum Speed (Rpm) | 24,000 |

| Collet Sizes Included | 1/4 in, 1/2 in |

| Base Type | Fixed base |

| Product Weight | 10 lb |

| Product Dimensions (W × H × D) | 9.5 in × 7.25 in × 10.75 in |

| Cord Length | 6 ft |

| Certifications | CSA Listed |

| Warranty | 3 Year Limited Warranty (plus 1 Year free service, 90 days satisfaction guarantee) |

| Returnable | 90-Day |

| Included Items | Motor pack, fixed base, 1/4 in and 1/2 in collets, wrench |

Related Tools

Related Articles

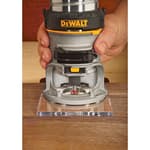

Fixed-base router motor with a 12 A, 2.25 HP (maximum) electronic variable-speed motor. Speed is adjustable with full-feedback control from about 8,000 to 24,000 rpm. Soft-start circuitry reduces startup torque. The tool uses a dust-sealed switch and features a spindle lock and flat top for single-wrench bit changes. Construction includes a die-cast aluminum base and a nickel-plated motor housing. Includes 1/4" and 1/2" collets and a wrench.

DeWalt 2-1/4 HP EVS Router Motor with Soft Start Review

I’ve kept a mid‑size router bolted into a table for years, and the DW618 has spent the last few months filling that role in my shop. It’s a 12‑amp, 2‑1/4‑horsepower, corded unit with variable speed, and on paper it checks most of the boxes a serious hobbyist or cabinet pro wants. In practice, it’s a capable, confidence‑building router with a few quirks worth knowing before you buy.

Build and setup

Out of the box, the DW618 feels like a purpose‑built tool. The die‑cast aluminum base and nickel‑plated motor housing create a solid, low‑flex platform, and the machining tolerances on my unit were clean—no burrs, no gritty slides. The motor latches snap positively into the fixed base, and the nickel plating really does help the motor glide smoothly during depth adjustments.

Setup is straightforward. Pop in the 1/4‑in or 1/2‑in collet (both are included), install a bit, and use the cam lock plus the micro‑adjust ring to dial in cutting depth. The micro‑adjuster lets you sneak up on settings in 1/64‑in increments, which is perfect for fitting joinery like rabbets and tenons. The clear LEXAN sub‑base gives decent visibility and accepts template guides, which I used for a set of arched door rails without any fuss.

A small but welcome touch: the detachable cordset. If you ever pinch a cord or want to rig a shorter cord for a dedicated table, it’s an easy swap and it makes storage simpler. The 6‑ft cord length is fine for handheld work, though it’s a bit short if you’re routing around a large bench.

Power and speed control

At 12 amps, the DW618 isn’t trying to be a shaper, but it’s plenty for 99% of what I do with a mid‑size router. I ran profiles, dadoes, mortises, and pattern cuts in hardwoods and plywood with no drama. The electronic variable speed ranges from 8,000 to 24,000 rpm, and the full‑feedback control keeps the bit at a steady pace under load. That’s noticeable when plunging into end grain or hogging out deep grooves; the motor doesn’t surge, and the cut feels consistent.

Soft start is excellent. There’s no wrenching twist on startup, which matters both in a handheld cut and when the router is bolted under a table; your workpiece doesn’t jump when you flip the switch. Speaking of, the dust‑sealed switch is firm and positive—it’s not a cheap rocker—and it’s held up fine in my pretty dusty shop.

If you routinely swing big panel‑raising bits, you’ll still want to stage cuts and drop the speed to the low end (8,000–12,000 rpm). The DW618 will do it, but like every router in this class, you’re better served by a couple of light passes than one heroic cut.

Ergonomics and handling

In the fixed base, this router balances well. The rubber overmold handles have a tacky, not squishy, feel and give you good leverage when following an edge guide or template. At about 10 lb with the base, it’s on the sturdy side for handheld profiling, but the mass damps vibration and helps produce cleaner edges, especially on long passes with a flush‑trim bit.

Noise is what you’d expect from a 2‑1/4‑hp router: not quiet, not obnoxious. Hearing protection is still a must. Vibration is low for the class; I can run it for long sessions without tingling hands.

Precision and adjustments

Depth setting with the ring is predictable. Unlock, rotate the motor in the nickel‑plated sleeve, lock. I can sneak up on a fit quickly, and the scale is honest enough that 1/64‑in tweaks actually match what I see in the cut. The “flat top” on the motor housing is more useful than it sounds—I flip the router upside down on the bench to measure bit projection off the base, and it sits steady without rocking.

One caution: keep the adjustment threads clean. Any router will get pitch and dust on the moving parts; a quick brush and a shot of dry lube keeps the ring turning like new. Neglect it and the fine threads can feel sticky.

In a router table

I set the DW618’s fixed base into a simple plate in my shop‑made table. There’s no dedicated above‑table adjust in this kit, but the quick‑release latches make it fast to drop the motor for bit changes. The constant‑speed electronics shine in a table—edge profiles on maple and long plywood dadoes were uniform without burning. For fence‑guided cuts where repeatable height matters, the micro‑adjust ring is repeatable enough that I didn’t miss a lift for most operations.

If you’re running production volume or doing lots of fine on‑the‑fly height tweaks, a router lift is still nicer. But for a compact table, this setup is efficient and budget‑friendly.

Bit changes and collets

The spindle lock enables single‑wrench bit changes, which is handy overhead in a table. The lock on my unit engages positively with minimal slop, and I’m not hunting for the detent. If you’re a two‑wrench purist, that’s a preference call; I’ve had no issues with the single‑wrench system.

The multi‑slot, self‑releasing collets are excellent. Bits pop free with a light crack of the wrench—no stuck bits, even after heat‑soaked pattern routing. Use the 1/2‑in shank whenever you can; it’s stiffer, quieter, and cuts cleaner.

Dust and maintenance

There’s no built‑in dust port on the fixed base, so collection depends on the bit and fence setup. With an over‑fence hood and shop vac, I captured most chips on edge profiles and dadoes. For mortising or freehand plunges, expect to manage chips with pauses or an assistant with a hose. Maintenance is minimal: blow out dust, keep the baseplate clean, and wipe the housing threads.

Quirks and limitations

- No above‑table height adjust in the fixed base. The quick‑release helps, but if you change heights constantly, budget for a lift or a dedicated height adjuster.

- Speed dial placement is fine, but it’s easy to nudge if you death‑grip the motor during handheld routing. A quick pre‑cut check became habit.

- The included cord is only 6 ft. For table use, I prefer a longer pigtail to reach a switch box without an extension.

- Like most in its class, heavy, wide bits demand multiple passes. That’s normal, but worth stating.

On the quality front, my unit has been reliable, starts clean, holds speed, and locks solidly in the base. As with any precision tool, a quick inspection on day one pays off: check that the depth ring turns smoothly, the motor latches lock tight, and the collet seats evenly.

Service and warranty

DeWalt backs the DW618 with a 3‑year limited warranty, a year of free service, and a 90‑day money‑back window. It’s not a throwaway tool, and the detachable cord and common‑pattern sub‑base make servicing or accessorizing easy.

Who it’s for

- Ideal for: Hobbyists to small‑shop pros who want one mid‑size router to handle edge profiles, dadoes, template work, and table duty without fuss.

- Works well in: A compact router table or handheld with guides and templates.

- Consider alternatives if: You need integrated dust collection, above‑table height adjustment, or you regularly swing massive bits and want a true 3+ hp motor.

Recommendation

I recommend the DW618 as a dependable, versatile mid‑size router for both handheld work and router‑table duty. It combines smooth electronic speed control, a genuinely useful soft start, and precise depth adjustments in a durable chassis. The self‑releasing collets and flat‑top/spindle‑lock combo make real‑world bit changes less of a hassle, and the nickel‑plated housing keeps adjustments smooth over time. You’ll need to manage dust with external solutions, and heavy cuts still require staged passes, but those are common trade‑offs in this class.

If you’re building cabinets, furniture, or doing regular trim and template work, this router has the power and control to do it cleanly—and the ergonomics to do it comfortably. Add a plunge base later if you need it, and it grows with your workflow. For the balance of performance, features, and price, it earns a permanent spot in my shop.

Project Ideas

Business

Custom Sign and Plaque Shop

Offer address plaques, business logos, and gift signs using templates, V-groove lettering, and inlay/epoxy fills. Tier pricing by size, complexity, and finish. Fast bit changes and accurate depth control enable efficient batching and consistent quality.

Slab and Cutting Board Flattening Service

Provide router-sled flattening for hobbyists and makers who lack the equipment. Charge by square footage and thickness, with add-ons for edge profiling and finish sanding. The 2-1/4 HP motor with feedback control maintains cut quality under load.

Mobile Countertop Cutout and Edge Profiling

Use templates and flush-trim bits to create sink and cooktop cutouts in butcher block or laminate, then route roundovers/chamfers for finished edges. Offer on-site service with dust control, charging per cutout and per edge profile.

Door and Cabinet Hardware Mortising

Serve contractors and DIYers with precise hinge, strike plate, and pull recesses using routing jigs. The soft start and micro-depth adjustment deliver clean, repeatable mortises quickly, ideal for punch-list and renovation work.

Small-Batch Trim and Molding Production

Mount the router in a table and produce custom profiles—beads, coves, ogees—on-demand. Sell by the linear foot and specialize in matching discontinued or historic profiles using stacked passes. Constant-speed under load keeps profiles crisp across runs.

Creative

Personalized Hardwood House Sign with Inlay

Use letter templates and a 1/4 in V-groove or straight bit to route names/numbers, then inlay contrasting wood or tinted epoxy. The micro-fine depth control ensures consistent inlay depth, and variable speed lets you tune for dense woods. Finish with a roundover edge using a 1/2 in shank bit for a professional look.

Cutting Boards with Juice Grooves and Finger Holds

Glue up hardwood panels, then route a perimeter juice groove with a core box bit and add ergonomic finger holds using a template and flush-trim bit. Round over or chamfer edges. The soft-start and constant-speed feedback help maintain clean grooves without burning.

Nested Circle Trays and Serving Platters

Make a simple circle-cut jig to route perfect round trays in multiple sizes. Add a shallow recess (rabbet) for a base or leather insert, and apply a gentle cove/roundover to the rim. The clear sub-base improves visibility for precise depth transitions.

Live-Edge Coffee Table with Router-Sled Flattening

Build a router sled and flatten a slab in light passes. Add bowtie keys using a template and straight bit, then chamfer edges. The 1/2 in collet and constant-speed control keep heavy bits cutting smoothly across varying grain.

Mid-Century Wall Shelf with Pattern-Routed Brackets

Create a master template for arched or geometric brackets, then flush-trim multiple copies for a matched set. Route a precise rabbet or dado for the shelf using micro-fine depth adjustment, and finish edges with a small roundover.