Features

- Resharpenable cutting edge for extended life

- Quick-set knives for easy setup

- Durable high-speed steel construction

- Suitable for planing wooden studs and hardwoods

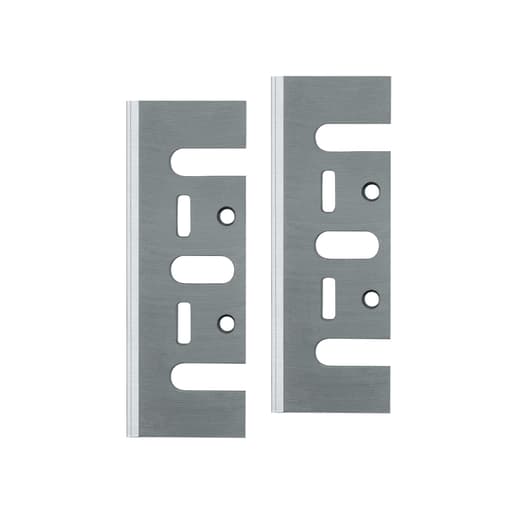

- Pack contains two blades

Specifications

| Material | High speed steel (HSS) |

| Length | 3-1/4 in |

| Compatible With | DW680K (D26676, D26677) and Makita N1900 planers |

| Package Quantity | Pack of 2 blades |

| Resharpenable | Yes |

| Warranty | 30 Day Money Back Guarantee |

Related Tools

Related Articles

Replacement planer blades made from high speed steel. They have a resharpenable cutting edge and are designed for use with specific bench planers. Blades are supplied in a two-count pack and use a quick-set knife system for installation.

DeWalt High Speed Steel Blades Review

A straightforward upgrade for handheld planers

Swapping in a fresh set of blades can make an old handheld planer feel new again. That was my experience with these DeWalt HSS blades: quick to install, predictable to set, and capable of producing a clean, consistent surface on both framing lumber and hardwood trim. They’re simple parts, but the details matter—steel quality, edge geometry, and how easily you can dial them in on the cutterhead. On all three counts, these blades hit the mark for everyday carpentry and shop work.

What stands out

- High-speed steel that sharpens well and leaves a fine finish

- A quick-set design that makes alignment painless

- True fit in both DeWalt’s DW680K/D26676/D26677 and Makita’s N1900 platforms

- A practical two-pack: one in the planer, one in the pouch

- Resharpenable edge that extends service life

These aren’t boutique knives. They’re workhorse blades intended for real jobsite material—studs, softwood trim, and common hardwoods—and they deliver a dependable cut without fuss.

Setup and fit

I installed one set on a DW680K and the other on a Makita N1900 to check compatibility. The fit was spot on in both cases. The quick-set system on the DeWalt made alignment straightforward: the locating features on the cutterhead register the blade, eliminating the fiddling that older jacking-screw systems often require. From opening the package to first pass took about ten minutes, including a quick wipe-down of the cutterhead to remove pitch.

If you’re installing on a Makita N1900, the process is nearly as painless. There’s a bit more attention needed to ensure the edge projects evenly across the shoe, but a straightedge bridging the front and rear shoes makes this easy. Lightly snug the gib screws, tap the blade to final position if needed, then torque in sequence. Either way, check the center of the blade carefully—on some planers, it’s easy to set the ends correctly while the center sits a hair proud.

A couple of practical notes:

- Clean the cutterhead pockets before seating the blades; a tiny chip of debris is enough to throw off the setting.

- Use moderate torque and a clean driver bit; stripping a gib screw is a pain you don’t need.

- After installation, take a zero-depth pass on scrap and listen for any tick—if you hear it, you’ve got a proud spot.

Cutting performance

On SPF studs at a 1/32-inch depth of cut, the blades produced a smooth, satiny surface that needed minimal sanding. I ran long bevels on door edges and chamfers on stair skirt boards without chatter. Chip ejection was clean, even on full-width passes, and the planer tracked well across knots without pulling.

Switching to hardwood, I planed red oak and maple at a lighter cut, closer to 1/64 inch, and slowed my feed rate slightly. The finish stayed crisp with only faint knife lines, the kind you remove with a few passes of 180-grit. Tear-out stayed minimal on straight-grained stock; on reversing grain, a shallower cut and a slower pace kept things under control. That’s typical HSS behavior—very workable if you respect grain direction and depth settings.

Where these blades shine is repeatable, clean stock removal across jobsite materials. Trimming swollen door edges, flushing pocket screw joints, fitting studs to a line, or taking down proud edges on built-ins—those are the tasks where they earn their keep.

Edge life and sharpening

HSS isn’t carbide, and that’s a good thing in many scenarios. The edge hones cleaner and takes a keener bite, which translates into a nicer finish at light cuts. In my use, the blades held up well through a day of stud cleanup and several hardwood fitting sessions before I noticed any degradation in cut quality. When I did, a quick touch-up on a diamond plate followed by a fine stone restored the edge.

Sharpening tips that worked well for me:

- Maintain a primary bevel around 30 degrees with a light micro-bevel (roughly 35 degrees). This balances sharpness and durability.

- Hone the full length to keep both blades matched; mismatched edges invite ridges.

- Avoid overheating. If you use a powered grinder, keep passes light and cool often—HSS tolerates heat better than carbon steel, but color change means you’ve gone too far.

- Take a moment to remove pitch and resin with a bit of mineral spirits before honing.

Because they’re resharpenable, you can expect multiple life cycles from a single set, provided you avoid hidden fasteners. If you routinely plane reclaimed lumber or MDF, check edges more often—glue lines and silica in composites blunt HSS faster than solid wood.

Compatibility notes

The blades are 3-1/4 inches and slotted correctly for:

- DeWalt DW680K and its siblings D26676 and D26677

- Makita N1900-series planers

They seated securely on both cutterheads and ran true with no detectable vibration. If your planer uses a quick-set knife system, you’ll appreciate how quickly these register. Always verify projection with a straightedge before you plunge into a finished surface.

Where they fall short

- Not designed for heavy abuse. HSS will nick if you hit a finish nail. That’s true of almost any handheld planer blade, but it’s worth stating. Sweep for fasteners or use a metal detector on suspect stock.

- Less ideal for abrasive composites. If you live in MDF, particleboard, or plywood with hard glue lines, expect more frequent touch-ups. Carbide might be a better fit for that niche, though you’ll trade away easy sharpening.

- No frills. These are straightforward blades—no reversible double edges or exotic coatings. For most users, that’s fine; just know what you’re buying.

Value and warranty

The two-pack format works well. I kept one blade set in the planer and one in the kit, which meant I could swap mid-job and sharpen at the bench later. The 30-day money-back guarantee adds a bit of reassurance, but the real value is in the resharpenable edge. Over time, that stretches your dollar further than disposable knives, especially if you already maintain a sharpening setup.

Tips for best results

- Take shallow passes, especially on hardwoods. Multiple light cuts beat one heavy cut for finish and blade life.

- Wax the planer’s shoe. Reduced friction means cleaner work and less heat at the edge.

- Keep chips moving. A clear dust path reduces recuts, which can dull edges.

- Mark your blades. After each sharpening, note the cycle with a dot—rotate usage so both blades wear evenly.

- Store the spare properly. The factory sleeve protects the edge; use it.

Final recommendation

I recommend these DeWalt HSS blades for anyone running a 3-1/4-inch handheld planer—particularly owners of the DW680K/D26676/D26677 and Makita N1900. They install quickly, produce a clean finish across softwoods and common hardwoods, and sharpen predictably. If your work leans toward general carpentry, trim fitting, and shop tasks in solid wood, they’re an easy choice that keeps your planer cutting at its best. If you primarily machine abrasive composites or reclaimed stock full of surprises, consider keeping a carbide set for those days. For everything else, these blades strike the right balance of performance, simplicity, and long-term value.

Project Ideas

Business

Door Edge Planing Service

Offer a fast, on-site fix for sticking or swelling doors. The 3-1/4 in planer is perfect for door edges, HSS blades handle paint and hardwood, and the quick-set system means rapid blade swaps—ideal for property managers and realtors.

On-Site Scribing & Fitment

Provide precision scribing of shelves, countertops, and trim to uneven walls and floors. Market to kitchen installers and custom closet companies; resharpenable HSS blades reduce consumable costs when working hardwoods and laminates.

Reclaimed Accent Wall Kits

Source, de-nail, and lightly plane reclaimed boards to remove splinters while preserving character, then bundle by square footage for DIY accent walls. Resharpenable HSS blades pay for themselves when boards contain hidden grit.

Hand-Planed Charcuterie Boards

Produce small-batch boards with a distinctive faceted, hand-planed finish and clean chamfers. HSS edges leave a crisp surface on maple or walnut; two-blade packs minimize downtime between resharpening cycles.

Blade Sharpening & Swap Program

Run a local pickup/drop-off sharpening service for DW680K/D26676/D26677 and Makita N1900-compatible blades. Offer loaner two-packs and subscriptions for contractors to ensure sharp knives and minimal downtime.

Creative

Faceted Furniture Legs

Transform square legs for stools or side tables into tapered, faceted profiles using the 3-1/4 in hand planer. The durable HSS, resharpenable blades let you take controlled, clean chamfers on hardwoods like oak and ash, and the quick-set knives speed fine depth adjustments between passes.

Live-Edge Wall Shelves

Flatten the back face and top of small live-edge slabs for floating shelves, then add consistent chamfers for a refined look while preserving the natural edge. HSS blades handle mixed grain and knots; the two-pack lets you swap quickly if you nick a blade.

Reclaimed Wood Picture Frames

Lightly plane pallet or barn wood to reveal grain while keeping patina, then bevel the outer edge to create custom frame mouldings. Resharpenable HSS edges tolerate occasional grit from reclaimed stock and the quick-set system minimizes setup time.

Scribed Built-In Shelves

Build alcove or closet shelves that fit perfectly against wavy plaster by scribing and planing to the line. The 3-1/4 in width is ideal for tight spots, and sharp HSS blades give clean, controlled shavings on softwood studs and dense hardwood edging.

Decorative Beam Chamfers

Add long, even chamfers and a subtle hand-planed texture to faux beams, mantels, or stair treads. High-speed steel holds an edge through long runs, and the quick-set knives keep your bevels consistent across multiple pieces.