Features

- Diamond-reinforced edge for chip-reduced cutting

- Continuous rim design for smooth cuts in tile

- Can be used wet or dry

- XP2 and XP4 cutting matrix options for extended life (XP2 ≈ 2× standard, XP4 ≈ 4× standard)

- Laser-cut expansion slots (on XP2/XP3) to reduce blade warping from heat

- Compatible with a variety of cutters and power tools

Specifications

| Blade Diameter (In) | 4 |

| Blade Thickness (In) | 0.06 |

| Rim Type | Continuous |

| Saw Blade Material | Diamond |

| Material Cut | Tile (wet or dry); masonry |

| Teeth Per Inch | 1 |

| Number In Package | 1 |

| Power Tool Accessory Type | Specialty Blade |

| Ideally Used With | Circular saws |

| Returnable | 90-Day |

| Cutting Matrix Options | XP2, XP4 (premium variants may include laser-cut expansion slots) |

Related Tools

Related Articles

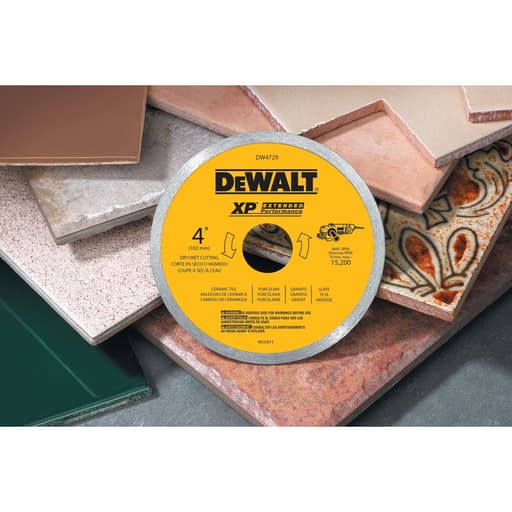

4 in. ceramic tile circular saw blade with a diamond-reinforced continuous rim. Designed for wet or dry cutting of tile and masonry materials. Compatible with a range of cutters and power tools. Optional cutting matrix choices (XP2, XP4) increase wear life; some premium variants include laser-cut expansion slots to help reduce heat-related warping.

DeWalt 4 in. Ceramic Tile Circular Saw Blade Review

A compact tile blade that punches above its size

A 4-inch diamond blade is one of those consumables you only notice when it lets you down. I’ve been running this DeWalt tile blade on a 4-1/2-inch angle grinder and a compact tabletop tile saw across a mix of ceramic wall tile, dense porcelain floor tile, and a few light masonry tasks. It’s a continuous-rim design with a diamond-reinforced edge, so the promise is straightforward: smooth, low-chip cuts you can run wet or dry. In practice, that’s largely what I got—provided I matched the technique to the material and didn’t rush the cut.

Setup, fit, and compatibility

The blade’s 4-inch diameter and thin 0.06-inch kerf make it a natural match for compact gear. On my grinder, it mounted without fuss and tracked true with no noticeable wobble. On a small tile saw, the blade’s narrow kerf felt precise and produced a clean line that was easy to follow. Depth is the predictable limitation with a 4-inch disc. You’ll get roughly an inch of usable cutting depth on a grinder—enough for most tile, not enough for thick pavers or stone slabs. If you plan on long rip cuts through thick material, step up in blade size or use a rail saw.

One detail worth noting: continuous-rim blades excel at cleanliness, not absolute speed. If your priority is ripping through concrete block in a hurry, a segmented rim would be faster. But for tile—especially glazed ceramic and porcelain—this rim style is the right call.

Cutting performance: ceramic and porcelain

On glazed ceramic wall tile, the DeWalt tile blade is easy to like. With light pressure and a steady feed, I consistently saw crisp edges straight off the cut. Taping the cut line and scoring a shallow pass before finishing helped keep the glaze intact on glossy tiles. Running the small saw wet produced the best surfaces; dry grinder cuts were nearly as good provided I took multiple shallow passes and didn’t force the blade.

Porcelain is the tougher test, and where some blades chip, skate, or overheat. On 3/8-inch porcelain floor tile, the blade stayed controllable and produced acceptably clean edges—not glassy smooth, but well within grout-hiding range. A few conditions improved results substantially:

- A shallow face score before full-depth cutting

- A modestly slower feed rate

- Occasional water misting, even during “dry” cuts

- A dressing pass on a scrap or dressing stone if the rim started to glaze

With those habits, I could notch L-cuts, plunge cut outlets, and make small radius adjustments by easing the blade on its edge to “grind” a profile. That kind of control is what I want from a continuous-rim tile blade, and this one delivered.

Heat management and life

This blade can run dry, and I did plenty of cuts that way on the grinder. Long, continuous dry cuts in dense porcelain will build heat quickly. When I heard the pitch rise or felt the tool bog slightly, a short pause or a quick dip to cool made a clear difference. On the compact tile saw with water, heat was a non-issue and the cut quality jumped a notch.

DeWalt offers XP variants (XP2 and XP4) that use a different cutting matrix aimed at longer life, with some versions adding laser-cut expansion slots to help with heat. I ran the standard blade for small to medium projects and found life perfectly acceptable—a bathroom worth of ceramic with extra cuts to spare. For extended runs in porcelain or back-to-back projects, the XP upgrades are worth considering. The XP blade I tested maintained its cutting rate longer before glazing and ran a bit cooler on dry passes. If you’re a frequent tile cutter, the extra cost is easy to justify; if you’re doing a kitchen backsplash and a bathroom niche, the standard blade is fine.

Accuracy, feel, and noise

With its thin kerf and continuous rim, the blade tracks predictably. I rarely had to fight deflection; when deflection did show up, it was user error—forcing the cut on a dry pass or twisting mid-plunge. Let the diamonds do the work and the kerf stays honest. On a grinder, vibration was minimal and the acoustic tone stayed even unless I pushed too hard. On a wet saw, it ran quiet, with less “singing” than some economy continuous rims I keep for rough cuts.

Edge cleanup was modest. On porcelain, a quick pass with a rubbing stone or a diamond hand pad knocked down microchip edges in seconds. On ceramic, many cuts were grout-ready without additional touch-up.

Versatility beyond tile

The blade is billed for tile and masonry, and it will indeed nibble through cement backer board, soft brick, and even corner-grind cured thinset without complaint. Just remember that the continuous rim favors finesse over aggression; if I needed to hog out a control joint in concrete or chop a stack of pavers, I’d grab a segmented blade. For mixed remodel tasks—trim a porcelain tile, notch a backer board, clean a rough edge—this blade handled it all without feeling out of place.

Technique tips that made the difference

A few working habits maximized performance and minimized chipping for me:

- Mark both faces and score the glazed face first with a shallow pass.

- Use painter’s tape on glossy ceramic to help support the glaze.

- Keep the cut line wetted or take short dry passes; avoid a hard, continuous dry push on porcelain.

- Dress the rim briefly on a scrap or dressing stone if the blade starts to polish and slow down.

- Support the tile fully, especially near the end of a cut, to prevent breakout.

None of these are exotic, but they turn a good blade into a consistently clean performer.

Limitations and nitpicks

The fundamental limitation is size. At 4 inches, your maximum depth and your stability on very long rips are constrained. For large-format tile with long exposed cuts, a larger wet saw blade will give straighter lines with fewer setup tricks. Also, while the blade can be run dry, it appreciates cooling; if your workflow is all dry, all day, plan on shorter duty cycles or step up to an XP variant with better heat tolerance.

Finally, continuous-rim cleanliness is paid for in speed. If you’re coming from a fast, segmented masonry blade used on brick or block, this DeWalt will feel slower on straight, non-glazed materials. That’s a tradeoff I’ll take for tile work.

Value and who it’s for

For pros and serious DIYers who cut tile regularly, the standard version is a dependable workhorse, and the XP options extend life meaningfully for porcelain-heavy workloads. The kerf is precise, the rim is consistent, and the compatibility with a variety of compact tools makes it easy to keep in the kit. Occasional users will appreciate that it runs well without water, but those who set up a simple wet station will get better edges and longer blade life.

Recommendation

I recommend this DeWalt tile blade for anyone doing ceramic or porcelain tile work who values clean edges and predictable tracking over raw cutting speed. It excels at the tasks continuous-rim blades are made for: low-chip face cuts, controlled notches, and tidy plunge cuts in glazed material. Run it wet when you can, respect its size limits, and it rewards you with smooth, accurate results. If you’re tackling multiple rooms of dense porcelain or prefer long dry runs on a grinder, consider the XP variants for cooler running and longer life. For quick, clean tile work on compact tools, this blade is an easy yes.

Project Ideas

Business

On-Site Tile Scribing and Notching Service

Offer a mobile service to contractors and homeowners for precision cuts around outlets, door casings, and fixtures. The blade’s wet/dry versatility enables indoor or outdoor work. Use XP4 for longer life on dense porcelain and charge per cut or per hour.

Custom Mosaic Medallions for Installers

Fabricate ready-to-install medallions, borders, and niche accents from client-supplied tile. Provide templates and CAD-to-cut services, bundle with labeled layout sheets, and ship nationwide. The continuous rim delivers clean curves and tight tolerances that installers value.

Etsy/Market Shop: Tile Coasters and Trivets

Produce small-batch, design-forward coaster and trivet sets using offcuts of porcelain, ceramic, and stone. Offer personalization, mixed-material patterns, and gift packaging. Lean on XP2/XP4 blades for efficient batch cutting and low edge cleanup.

RV/Van Conversion Tile Specialist

Niche service installing lightweight tile features in mobile builds: compact backsplashes, shower niches, and table inlays. Precision dry-cutting reduces setup time; wet cutting used for fragile finishes. Market to van upfitters and overlanding communities.

Workshops and DIY Mosaic Kits

Host classes teaching beginner mosaics and sell pre-cut tile kits with patterns. Use the blade to prep safe, clean-edged pieces in-house. Diversify revenue with virtual classes, tool rental add-ons, and premium XP4-cut porcelain kits for advanced students.

Creative

Curved Mosaic Garden Stepping Stones

Design and cut tile petals, leaves, and flowing ribbons to create botanical mosaics on concrete pavers. Use the continuous rim for smooth, chip-minimized curved cuts and switch to wet cutting for porcelain or glassy tiles. Assemble with thinset and grout in contrasting colors for high-impact garden art.

Geometric Tile Coasters and Trivets

Cut small-format porcelain or marble into precise diamonds, hexagons, and arcs to form modern coaster and trivet sets. The 0.06 in blade thickness and diamond rim help keep edges clean, while XP2/XP4 options handle production runs. Package as color-coordinated sets with cork backing.

Upcycled Furniture Tile Inlay

Refurbish coffee tables, cabinet doors, and sideboards by insetting custom-cut tiles into routed recesses. Create medallions and borders with tight radii and miters using the continuous rim for smooth transitions. Seal with epoxy grout for a durable, spill-proof surface.

Custom Backsplash Accents

Turn ordinary subway tile into art by cutting chevrons, arabesque inserts, and scribed edge pieces around outlets and corners. Use wet cuts to minimize chipping on glossy ceramics and fabricate matching trim pieces from field tile for a bespoke look.

Slate or Porcelain House Number Plaque

Cut and inlay contrasting tile numbers into a slate or porcelain base. Bevel the edges for a finished look and mount to a weatherproof backing. The blade’s masonry capability allows clean scribing for tight-fitting numerals and decorative borders.