Features

- Shock‑resistant tool steel construction

- Heat treated to resist breakage and wear

- Hardened core for increased strength

- Zinc phosphate finish

- Snub‑nose design for fitment in bit holders

- Suitable for use with impact drivers

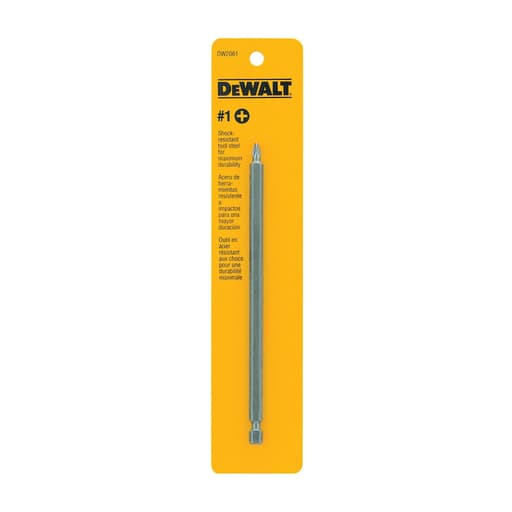

Specifications

| Drive Type | Phillips |

| Drive Size | #1 |

| Shank Type | Hex |

| Shank Size | 1/4 in |

| Material | Tool Steel |

| Finish | Zinc Phosphate |

| Length | 6 in |

| Suitable For | Impact Driver |

| Number Of Pieces | 1 |

| Product Pack Quantity | 1 |

Related Tools

Related Articles

Insert bits for driving #1 Phillips screws. Made from heat-treated, shock-resistant tool steel with a hardened core and a zinc phosphate finish. Intended for use in bit holders and compatible with impact drivers; designed to reduce stripping and resist breakage and wear.

DeWalt #1 Phillips 1" Insert Bit Tips Review

Why I keep a #1 Phillips insert bit at the ready

I reach for a #1 Phillips more often than I expect—cabinet hardware, outlet and switch plates, small electronics screws, and the occasional model railroad accessory all seem to use it. After months of mixed shop and site work, this DeWalt #1 Phillips insert bit has earned a permanent spot in my bit caddy because it does three things consistently well: it fits small Phillips heads cleanly, it resists chipping and rounding, and it plays nicely with a standard bit holder in tight spaces.

This is the short “insert” style bit (about an inch long) intended to live in a 1/4-inch hex bit holder. The snub-nose format gives you better control and a lower profile than a long power bit—handy behind hinges, under toe-kicks, and inside enclosures.

Fit and driving performance

Bit geometry matters most with #1 Phillips because small screws don’t leave much room for error. The tip on this bit is crisply ground and seats fully in #1 recesses without wobble. On #4–#6 screws in brass, zinc, and stainless, engagement is positive and cam-out is rare if you keep the driver aligned.

A few practical notes from use:

- On soft brass hinge screws, the bit’s clean tip helped prevent “chewing” the recess when starting by hand.

- On stainless sheet-metal screws, I felt less skating than with some bargain-bin bits—likely a combination of proper sizing and a crisp tip.

- In wafer-head electrical screws (typical for cover plates), the short bit plus holder kept the driver’s nose comfortably away from the wall, making alignment easier.

Phillips is designed to shed torque, and #1 heads do it sooner than #2. Technique still matters: pre-drill properly, use a clutch or low-speed setting, and let the bit do the centering before you apply torque. Do that, and this bit rewards you with smooth, predictable driving.

Durability and wear

Two things stand out about the build: the hardened core and the heat treatment. I can’t tear down the metallurgy, but the results show up in service life. After a couple hundred mixed fasteners—pine and poplar casework, sheet-metal brackets, and a small run of stainless pan-heads—the driving surfaces are still well-defined with no chips on the wings. The bit has some shiny wear on the black finish, but the edges remain crisp.

I intentionally abused it in a few ways:

- High-torque driver on a #6 screw into oak without waxing the threads—no tip fracture, just some audible cam-out when I pushed my luck.

- Off-axis driving in a pocket I couldn’t fully see—no twist at the neck, which is where inferior insert bits often snap.

It’s still an insert bit without a torsion zone, so there’s a limit to how much hammering and side load it will tolerate. But within reasonable use, the resistance to rounding and chipping is better than average.

Finish and corrosion resistance

The zinc phosphate finish is practical. It kills glare under shop lights, offers some corrosion resistance, and doesn’t feel slick in the bit holder. Mine has lived in a humid basement shop and on a few drizzly jobs; the finish shows standard rub marks but no rust blooms. If you toss bits into a damp pouch for weeks on end, any steel tool will complain, but this one holds up as well as I’d expect.

Impact driver compatibility

DeWalt calls it suitable for impact drivers, and I’ve used it in a 12V and 18V impact without drama. That said, #1 screws and impact pulses aren’t always a happy match. I treat it as “impact-capable” rather than “impact-optimized”:

- Keep speed low; most modern impacts allow a precision mode that works fine for #1 hardware.

- Use a good bit holder to avoid extra eccentricity.

- If you’re driving into hardwood or sheet metal, wax or pre-thread when possible.

Follow those steps and the bit will survive impact use while keeping small screw heads intact.

Bit holder and ergonomics

This is where the insert format shines. Paired with a magnetic bit holder:

- The short length improves control, especially when you start a screw one-handed.

- Swapping between tip types is fast if you keep a couple of inserts in your pocket organizer.

- In tight boxes and behind trim, the lower profile beats a 2-inch power bit.

Retention in the holder is positive; the hex tolerances feel snug, and there’s no rattle. The snub nose helps you get closer to the work without the bit flex you sometimes feel with longer shanks.

Marking and identification

A minor gripe: size markings on black phosphate bits can be hard to see. This one is marked, but in poor light “P1” isn’t immediately obvious. I dot-punched the shank for tactile ID, and that solved it. Color coding would be nice, but not a deal-breaker.

Use cases and technique

Where this bit excels:

- Cabinet and furniture hardware that uses #1 screws.

- Electrical cover plates and device screws that still spec #1.

- Small hobby builds and fixtures with #4–#6 Phillips fasteners.

- Tight clearances where a 1-inch insert in a stubby holder is the only way in.

Tips for best results:

- Match the screw head: a surprising number of “mystery” small screws are Pozidriv or JIS. If the fit feels mushy, stop and verify—you’ll protect both the screw and the bit.

- Let the bit seat fully before applying torque; a quick two-finger spin helps it find bottom.

- Use a clutch or impact precision mode to avoid overdriving small heads.

A note on length

You’ll occasionally see catalog entries that list this style as longer than it is. The insert I’m reviewing is the short, roughly 1-inch bit designed for use in a holder—not a 6-inch power bit. If you need reach, pick a dedicated power bit; if you need control and compactness, this insert is the right format.

Limitations

No tool is universal. A few boundaries to keep in mind:

- It’s not a torsion bit; if you routinely hammer #1 screws with a high-power impact, a torsion-style insert might give you a larger safety margin.

- It won’t save a mismatched screw; JIS and Pozidriv fasteners need their own tips.

- If you prefer extended reach without a separate holder, you’ll want a 2–3 inch power bit instead.

Value and alternatives

Sold singly, this bit is an easy add to a kit, especially if your current #1 is chewed up. Heavy users might prefer a multi-pack to spread wear and loss. In terms of performance, it lands above commodity insert bits thanks to better edge retention and a stronger core, even if it lacks the torsion zone you’ll see in premium impact lines.

Bottom line

The DeWalt #1 Phillips insert bit does the simple things right: clean fit, durable tip, and a compact format that makes small-fastener work less fussy. It’s been reliable across a mix of delicate and everyday tasks, and it holds up under reasonable impact use as long as you pair it with good technique.

Recommendation: I recommend this bit if you handle small Phillips screws and want a compact, durable insert for a standard bit holder. It’s a solid, no-drama choice for cabinet work, electrical punch lists, hobby projects, and any spot where a long power bit feels clumsy. If you primarily need extended reach or a torsion zone for heavy impact abuse, choose a longer torsion bit instead; otherwise, this insert belongs in your kit.

Project Ideas

Business

Cabinet & Hardware Tune‑Up Service

Offer a flat‑rate, 30–60 minute visit to tighten cabinet pulls, hinges, strike plates, and switch/outlet covers that commonly use small Phillips screws. The impact‑ready #1 bit speeds the job while reducing stripping on delicate hardware.

DIY Screw Art Kits

Sell pre‑drilled boards, templates, #1 screws, and a #1 insert bit in a bit holder as a complete kit for mosaics or string art. Monetize via online listings and craft fairs; add upsells for custom templates and premium screws.

Retail POP/Fixture Assembly

Provide on‑call assembly and maintenance for small retail displays and fixtures that rely on #1 screws. Fast, clean installs using impact‑compatible bits reduce store downtime and justify a recurring service contract.

Small Fastener Rescue

Specialize in removing and replacing stripped or loose #1 Phillips screws in cabinetry, furniture, and light appliances. Use fresh #1 bits for maximum bite, then upsell replacement screws and thread repair where needed.

Custom‑Branded Bit Bundles

Source #1 insert bits and package them with magnetic bit holders in branded sleeves for contractors, realtors, and hardware stores. Sell as promo swag or retail add‑ons; the hardened core and wear‑resistant finish make them a credible giveaway.

Creative

Screw-Depth Portrait Mosaic

Transfer a grayscale photo to a plywood board, pre-drill a grid, then drive #1 Phillips screws to different depths to create shading. The snub‑nose insert bit in a bit holder with an impact driver speeds placement and reduces cam‑out on small fasteners.

Mini Keepsake Box with Brass Hardware

Build small wooden boxes and install tiny brass hinges and latches with #1 screws for a refined look. The heat‑treated, hardened #1 bit minimizes stripping in soft brass when used with a clutch‑set driver and waxed threads.

Kinetic Gear Desk Toy

Laser- or scroll-cut plywood gears and assemble a hand‑cranked kinetic sculpture using #1 screws as pivots and spacers. The shock‑resistant bit handles repetitive driving into hardwood or Baltic birch without rounding fasteners.

Constellation String Art

Plot star maps on stained plywood, drive #1 screws at star points, then connect with thread to form constellations. The bit’s precise fit makes quick work of dense patterns without tearing the wood surface.

Travel Peg Game Board

Create a pocket-sized cribbage or tic‑tac‑toe board where short #1 screws act as removable pegs/markers. The zinc‑phosphate finished bit resists wear when repeatedly installing and removing screws for gameplay.