Features

- Micrograin carbide teeth (triple-edged) for durability

- Low-friction speedcoat finish

- Shouldered tooth tips to reduce kickback

- Precision laser-cut body slots to reduce vibration and noise

- Design aimed at maintaining edge sharpness

Specifications

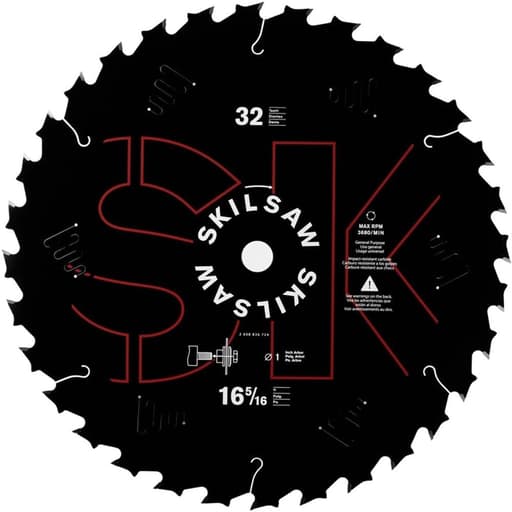

| Diameter | 16-5/16 IN. |

| Tooth Count | 32 |

| Kerf | 0.1 IN. |

| Tooth Material | Micrograin carbide |

| Coating | Dark speedcoat (low-friction) |

| Tip Style | Shouldered tips |

| Body | Laser body slots (precision-cut) |

Related Tools

Related Articles

Circular saw blade intended for general cutting. It uses micrograin carbide teeth to resist damage and retain sharpness. A low-friction coating is applied to reduce cutting resistance. Shouldered tooth tips and laser-cut body slots are used to reduce kickback, vibration and noise and to improve cut consistency.

Skil 16-5/16 IN. X 32T Saw Blade Review

Why I reached for this blade

Big beams and deep cuts are unforgiving, and a blade that’s merely “okay” on a 7-1/4 in saw can feel out of its depth on a 16-5/16 in beam saw. I put this 16-5/16 in, 32-tooth Skil blade on my worm-drive beam saw for a mix of LVL, glulam, and wet pressure-treated 6x material. Over several days of framing and trimming, I paid attention to how it started, how it stayed sharp, how it tracked through deep stock, and whether the features on the label actually showed up in the cut.

Setup and first impressions

Out of the sleeve, the dark low-friction coating looks uniform and clean, with crisp, consistent carbide tips. The plate is dead flat to the eye, and the laser-cut body slots are well executed—no burrs, no rough edges. The blade seated without fuss and spun true. On the first few cuts, I didn’t notice any telltale wobble or “shimmer” in the kerf, which can creep in with large-diameter blades if the plate or bore isn’t right.

Cutting performance on structural lumber

Ripping and crosscutting LVL and glulam: The 32T count hits a useful middle ground for a blade this size—aggressive enough to move through dense engineered stock without bogging, but with enough tooth engagement to keep the cut from looking ragged. On 3-1/2 in LVL rips and 6x glulam crosscuts, the blade kept a steady feed rate and the saw motor didn’t labor. The thin 0.1 in kerf helps here; it removes less material and reduces load, which matters on deep cuts where friction builds.

Wet pressure-treated 6x: This is usually where coatings get tested. The low-friction finish notably reduced the “sticky” feeling you sometimes get halfway through a saturated timber. I saw heat tint on the plate far less than I expect on a long rip, and I didn’t feel pitch building to the point of slowing the cut. The blade cleared chips well and didn’t leave burn marks unless I stalled in place.

Sheet goods and SIP edges: On plywood and OSB, the 32T grind is serviceable. It’s not a finish blade, but for trimming the edges of SIPs or cutting stacked sheets, it produced edges that were straight and surprisingly clean for a diameter this large. If you’re expecting furniture-grade faces without tearout, pair it with painter’s tape or a scoring cut; otherwise, it’s more than adequate for structural work.

Cut quality and tracking

Deep cuts magnify any tendency to wander. With this blade, tracking was predictable: if I let the blade do the work and kept a consistent feed, the kerf stayed straight even at full depth. Push too hard, and you can coax a hint of deflection in very dense stock—that’s the tradeoff with a thin kerf on a large diameter—but the laser-cut body slots mitigate it well. I noticed less vibration than I usually expect from a blade this size, and the saw felt planted, not skittery, entering and exiting the cut.

Edge quality is square and consistent. On crosscuts through dry Doug-fir 6x material, the exit side showed minor fuzzing but no big chips or splinter blowouts. On LVL, the faces were crisp enough that I didn’t need to tune with a plane unless the cut would be visible.

Noise, vibration, and feel

There’s no such thing as a quiet 16-5/16 in blade, but this one runs smoother than most. The laser-cut slots calm the plate; startup and spin-down feel balanced, with less “drum” resonance. In deep stock, there’s a lower-pitched hum rather than the sharp chatter you sometimes hear when a plate oscillates. I still recommend ear protection—this is a big, fast piece of carbide—but the overall tone is easier to live with on a long day.

Vibration at the handles was minimal, which makes it easier to follow a line and reduces fatigue. That stability also shows up in the face of the cut: less chatter translates to fewer micro scallops in the kerf walls.

Kickback resistance and safety

Shouldered tooth tips are there to temper the blade’s bite at the edges of the cut, and they seem to do their job. On plunge starts into beams and when exiting at full depth, the blade stayed composed. I didn’t experience any lurching or sudden grabs setting the toe of the shoe. That said, any blade of this size can punish sloppy technique. The design helps; it doesn’t replace proper support and steady feed.

Edge retention and durability

The micrograin carbide tips and the triple-edged grind held up well. After a week of structural cuts—LVL, green lumber, and some plywood—the teeth still looked sharp and the cut quality hadn’t degraded meaningfully. I didn’t lose any tips, and I didn’t see microchipping, even after working through knots in dense stock. The dark coating resisted gumming; a quick wipe-down at the end of the day was enough to keep it clean. If you keep resin off and avoid overheating, I’d expect a healthy resharpening cycle out of this blade.

Where it shines

Structural and timber framing: If you’re building decks, pergolas, or timber elements where 6x and engineered beams are common, this blade keeps productivity high with reliable cut quality.

Long rips in deep stock: The thin kerf and low-friction finish reduce motor strain and keep feed rates reasonable, limiting heat buildup.

General-purpose large-diameter use: For most tasks a big beam saw sees—plunge cuts, gang cuts through laminated members, trimming SIP edges—this strikes a good balance of speed and finish.

Where it’s less ideal

Fine finish work on visible faces: The 32T count is a pragmatic choice for production cutting. For pristine, furniture-grade crosscuts in hardwoods or delicate veneers, a finer-tooth blade would be a better match.

Overly aggressive feed in dense composites: If you force the cut, you can induce a touch of deflection simply because of the thin 0.1 in plate. Let the blade clear chips and it tracks straight.

Practical tips from use

Support the work fully, especially at the exit: It reduces the chance of splintering and helps the blade exit smoothly.

Keep the feed steady: This blade rewards consistent pressure; pushing too hard adds heat and can reduce accuracy.

Clean the plate regularly: The dark coating resists buildup, but wiping off resin with a blade cleaner extends edge life and keeps the low-friction feel.

Let it cool on marathon cuts: On very long rips in wet stock, a brief pause between passes keeps heat in check and preserves sharpness.

Value

For a specialized diameter, options are limited, and prices can climb. This Skil blade slots into a sensible price-to-performance band. You get a durable micrograin carbide tooth line, a thin kerf that pays dividends in speed and load reduction, and a plate that feels well made. The combination of features—shouldered tips, low-friction coating, and laser-cut slots—aren’t marketing fluff; they show up in the cut.

Final thoughts and recommendation

This 16-5/16 in 32T blade does what I want a big-beam general-purpose blade to do: it starts true, runs smooth, tracks straight through deep stock, and stays sharp through a solid workload. The low-friction coating and thin kerf reduce strain on the saw, while the laser-cut body slots and shouldered tips add noticeable stability and predictability. It’s not a finish blade, and it won’t fix poor technique, but for structural lumber, engineered beams, and jobsite production cutting, it’s a reliable, well-mannered partner.

I recommend this blade. If your work involves regular cuts in 6x, LVL, or glulam, you’ll appreciate the balance of speed, control, and edge retention, and you’ll spend more time cutting and less time fighting heat, chatter, or a wandering kerf.

Project Ideas

Business

Mobile Heavy-Timber Cut & Fit Service

Offer on-site cutting and joinery for pergolas, porches, carports, and timber-frame remodels. The 16-5/16 in. blade enables single-pass cuts on 6x material, precise shoulders, and clean half-laps. Market to contractors lacking beam saw capacity; price per cut or day rate plus travel.

Reclaimed Beam Mantels (Ready-to-Install)

Source reclaimed beams, scan for fasteners, and mill them into standard mantel sizes with clean faces, shadow kerfs, and hidden mounting slots. The durable micrograin carbide teeth and low-vibration design deliver consistent finishes. Sell online with custom lengths and finish options.

Custom Pergola/Carport Kits Cut-to-Fit

Pre-cut, label, and bundle heavy-timber pergola or carport kits for DIY clients and landscapers. Use the blade for accurate long crosscuts and notches, reducing on-site time for installers. Upsell stain, hardware, and delivery; provide assembly guides and layout plans.

On-Site Straight-Line Rip & Edge Prep for Slabs

Provide a mobile service to straight-line rip live-edge slabs and prep glue-ready edges for countertops and tables. The large diameter blade tracks cleanly on thick hardwood with a rail or straightedge, reducing shop bottlenecks. Bill per linear foot; partner with sawyers and furniture makers.

Precision Long-Beam Crosscut for Builders

Specialize in accurate cut-to-length service for LVL, PSL, and large dimensional lumber that exceed common miter saw capacity. The blade’s laser-cut body slots reduce vibration for square, consistent faces on long spans. Serve framing crews and deck builders; offer same-day site visits.

Creative

Timber-Frame Pergola With Half-Lap Joinery

Design a backyard pergola using 6x6 posts and 4x8 beams, cutting clean shoulders and half-lap joints with the 16-5/16 in. blade. The large diameter reaches through thick stock in a single pass, while shouldered tips and laser-cut slots keep plunge and crosscuts steady and low-vibration for tight-fitting joinery.

Beam Mantel With Shadow-Line Kerfs

Turn a solid beam into a modern mantel by adding crisp chamfers and decorative shadow-line kerfs. The low-friction coating helps maintain smooth feed on long passes, and the micrograin carbide teeth keep edges sharp when profiling dense woods like oak or maple.

Live-Edge Slab Coffee Table Pair

Split a wide live-edge slab into two matching coffee tables. Use a straightedge guide to rip to width and create clean crosscuts for matching end grain. The blade’s 32T balance gives a tidy cut on thick hardwood while the laser body slots help minimize wander on long rips.

Modular Raised Planter Boxes (4x6/6x6)

Build stackable planter modules from 4x6 and 6x6 timbers, notching corners with multiple kerf passes. The big diameter allows deep, consistent cuts for interlocking corners, and shouldered tips reduce kickback risk during plunge and notch starts.

Chevron Feature Wall From Reclaimed Planks

Create a large chevron wall panel by straight-lining reclaimed boards and making consistent angle cuts. The low-friction coating helps keep long bevels smooth, and the carbide teeth maintain edge quality across mixed, dense species (after fastener scanning).