Features

- Durable design for extended use

- 3.5 TPI Tooth Design

- Access slots for easier plug removal

- Increased visibility for precise placement

- Thermoset coating for reduced friction

- Lifetime tooth break warranty

- Made in the USA

- Suitable for various materials including metals, drywall, plastics, and wood

- 1-5/8" cutting depth

Specifications

| Hole Diameter | 3 1/2 in |

| Cutting Depth | 1-5/8 in |

| Usable Length | 1.5 in |

| Weight | 0.68 lb |

| Dimensions | 3.5 in x 3.5 in x 1.875 in |

| Pack Qty | 9 Pack (Bulk) |

| Rpm Stainless Steel | 45 |

| Rpm Mild Steel | 95 |

| Rpm Cast Iron | 65 |

| Rpm Aluminum | 145 |

| Packaging | Bulk |

Related Tools

Related Articles

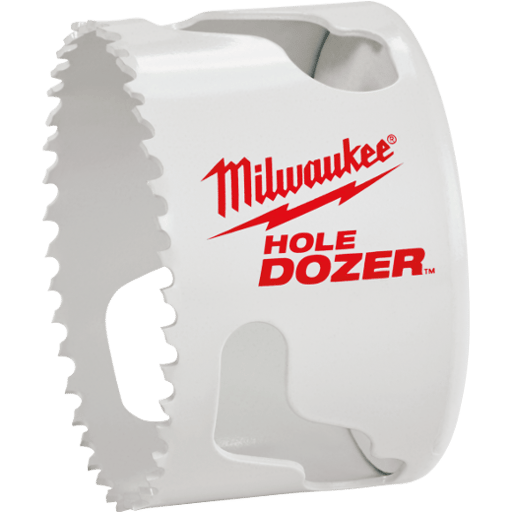

The Hole Dozer™ Bi-Metal Hole Saw features a 3.5 TPI tooth design designed for durability in metal applications. It includes features that assist in plug removal and enhance visibility for accurate placement.

Milwaukee Hole Dozer Bi-Metal Hole Saw Review

The Milwaukee Hole Dozer™ Bi-Metal Hole Saw has quickly become one of my favorite tools in my collection, and it's easy to see why. Whether you're a seasoned contractor or a weekend warrior, you'll appreciate the performance, durability, and thoughtful design that Milwaukee has packed into this modestly sized yet powerful tool.

Precision and Efficiency in Design

From the moment I first held the Hole Dozer, I could tell it was built with quality in mind. The weight of the saw (0.68 lb) feels just right—not too heavy to handle comfortably, but substantial enough to feel sturdy and reliable. The 3.5 TPI (teeth per inch) tooth design is particularly noteworthy. It provides a perfect balance between aggressive cutting and smooth operation, gliding through various materials with minimal resistance.

Cutting Through Any Challenge

One of the first tests I put the Hole Dozer through was drilling holes in some old hardwood flooring. Typically, this task can be quite challenging due to the density of the wood. However, the Hole Dozer performed admirably, biting into the wood without any of the usual "walking" or "dancing" that I've experienced with other hole saws. It made precise cuts exactly where I needed them, and the clean finish was impressive.

The Hole Dozer is not just a one-trick pony; it's versatile enough to handle a variety of materials. I used it on drywall, plastic, and even some thin metals. Each time, it performed consistently well. The thermoset coating is another feature that deserves mention. It noticeably reduces friction, which not only makes cutting easier but also helps keep the saw cooler, extending its lifespan.

Thoughtful Features for Real-World Use

One issue I often encounter with hole saws is the difficulty of removing plugs after cutting. Milwaukee has addressed this common problem with strategically placed access slots, making plug removal remarkably easy. I found myself spending less time wrestling with stuck plugs and more time getting the job done.

Another practical feature is the increased visibility for precise placement. The design allows you to see exactly where you're cutting, which is crucial for tasks that require a high degree of accuracy. This feature alone can save you from the frustration of having to redo a cut because it wasn't perfectly aligned the first time.

Durability and Reliability

Durability is a key factor for any tool, and the Hole Dozer doesn't disappoint. The bi-metal construction adds to its longevity, enabling it to withstand repeated use without significant wear. I was particularly impressed by how well it held up after multiple projects. Even after cutting through dense hardwood and thick plastics, the teeth remained sharp and effective.

The lifetime tooth break warranty is a testament to Milwaukee's confidence in their product. While I haven't had to take advantage of this warranty, it's reassuring to know that it's there. This kind of support from a manufacturer speaks volumes about the reliability of the tool.

Versatility in Application

I've used the Hole Dozer for a wide range of applications, from installing plumbing fixtures to creating openings for electrical wiring. Its ability to cut through different materials like metal, drywall, and wood makes it a versatile addition to any toolkit. One standout performance was when I used it to drill holes in log cabin walls for a plumbing project. Despite the thick and varied materials, the Hole Dozer handled the task without any issues.

The 1-5/8" cutting depth is generally sufficient for most standard tasks, and the varied RPM recommendations for different materials (e.g., 45 RPM for stainless steel, 95 RPM for mild steel) ensure you can optimize your cutting speed for efficiency and tool longevity.

User-Friendly and Accessible

Ease of use is another area where the Hole Dozer shines. The setup is straightforward, and swapping out different sizes is quick and hassle-free. The design minimizes the chances of the arbor getting jammed, a problem I've encountered with other brands. This not only saves time but also reduces the frustration that can come with complex projects.

The tool's usability extends to its handling. It cuts straight and true, requiring minimal force to guide it through the material. This makes it suitable for both professionals and DIY enthusiasts. Whether you're drilling a hole for a new door handle or creating an opening for a dryer vent, the Hole Dozer simplifies the process.

Final Thoughts

In summary, the Milwaukee Hole Dozer™ Bi-Metal Hole Saw is a robust, reliable, and versatile tool that delivers on its promises. Its durable construction, thoughtful design features, and impressive cutting performance make it a valuable addition to any toolbox. The ease of plug removal, increased visibility, and reduced friction from the thermoset coating are practical enhancements that improve the overall user experience.

Would I recommend the Hole Dozer? Absolutely. Its ability to handle a wide range of materials with ease and precision, combined with its durability and user-friendly design, make it a standout choice for both professional contractors and DIY enthusiasts. Whether you're tackling small home improvement projects or more demanding construction tasks, the Hole Dozer is a tool you can rely on to get the job done right.

Project Ideas

Business

Custom Signage Business

Start a business creating custom metal and wood signs for businesses, homes, and events. Use the Hole Dozer™ Bi-Metal Hole Saw to cut out intricate designs and logos.

Furniture Design and Manufacturing

Launch a business designing and manufacturing unique furniture pieces, incorporating circular cutouts for aesthetic appeal or functional purposes such as cable management.

Home Renovation Services

Offer specialized home renovation services that include the installation of customized fixtures like doorknobs, light fittings, and plumbing features, ensuring precise cuts and placements.

Art and Craft Workshops

Host workshops teaching participants how to use the Hole Dozer™ Bi-Metal Hole Saw to create various crafts and DIY projects. This could be a great way to generate income and build a community.

Custom Automotive Parts

Create a niche business fabricating custom automotive parts, such as dashboards or speaker panels, requiring precise circular cuts. Offer bespoke designs tailored to client specifications.

Creative

Custom Metal Wall Art

Use the Hole Dozer™ Bi-Metal Hole Saw to cut precise circular designs out of metal sheets. These can be painted or left raw for an industrial look and used as wall decor.

Unique Light Fixtures

Create custom light fixtures by cutting holes of various sizes in metal or wood panels. These panels can be used as decorative covers for ceiling lights or lamps, creating unique lighting effects.

Personalized Clock Faces

Craft personalized clock faces by cutting circular shapes from wood, metal, or acrylic. Decorate them with paints, engravings, or other embellishments to make unique timepieces.

Custom Planter Holders

Design and create custom planter holders by cutting holes into wooden or metal panels. These can be used to hold small pots for indoor or outdoor plants, adding a touch of creativity to gardening.

DIY Speaker Enclosures

Build custom speaker enclosures by cutting precise speaker holes in wooden or metal panels. These can be used for home audio systems or portable speakers.