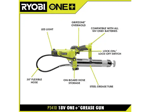

Features

- Right-angle coupler for accessing hard-to-reach zerk fittings

- Designed for use with cordless grease guns

- Rated for use at pressures up to 10,000 psi

Specifications

| Max Operating Pressure | 10,000 psi |

| Included | 1 grease gun coupler |

| Compatible Fittings | Zerk (grease) fittings |

| Coupler Style | Right angle |

| Weight | 0.26 lb |

| Warranty | 30 Day Money Back Guarantee |

Related Tools

Related Articles

A right-angle coupler designed to access recessed or hard-to-reach zerk (grease) fittings. Intended for use with cordless grease guns and compatible with common grease nipple profiles.

DeWalt Right Angle Grease Gun Coupler Review

Why I reached for a right‑angle coupler

Greasing chores are rarely about open access and perfect alignment. They’re about the zerk tucked behind a U‑joint yoke, the fitting buried under a guard, or the pin boss recessed so deep a standard coupler can’t approach it straight on. That’s exactly where the DeWalt right‑angle coupler earns its keep. I put it in the bag as a “maybe I’ll need it” attachment for my cordless grease gun, and it’s turned into a regular problem-solver around drivelines, mower decks, and loader pivots.

What it is

This is a compact, right‑angle coupler designed to snap onto standard zerk fittings and survive the output of a high‑pressure grease gun. It’s rated to 10,000 psi, weighs a quarter of a pound, and is sized to live in a service cart or truck pouch without fuss. There’s no trick latch or hose section—just a short, rigid right‑angle body with a standard jawed tip and a female end that mates to your grease gun whip hose.

Setup and first impressions

Threading it onto my whip hose was straightforward, and the fit was snug without needing sealant. The coupler seats with a positive “click” on most zerks and releases cleanly when you rock it off. The body feels like honest metal—no flex or sponginess when you lever it into position—and the overall length is short enough that the assembly doesn’t feel unwieldy at the gun.

In the hand, the right‑angle geometry immediately changes how you approach a fitting. Instead of trying to line up your gun in a straight shot, you come in from the side, slip the tip onto the zerk, and keep the hose and gun out of the obstacle course. That alone is worth it when you’re working in a pinch point where a straight coupler simply won’t go square.

In the field

I started with the easy wins: mower spindle zerks tucked under a deck lip and a pickup’s rear U‑joints. The coupler seated easily and held pressure without blowing off. I ran my cordless gun at a moderate speed and watched for the usual telltales—grease escaping around the jaw, the coupler trying to ride off the zerk, or the zerk pushing back. None of those showed up if I took the time to get square and support the coupler with a finger or two.

Where the right angle really helped was on recessed fittings in counterbored bosses. On a compact loader, a couple of the pivot pins sit behind gussets; a straight coupler hits the wall before it lines up. Coming in laterally let me keep the nozzle perpendicular to the zerk with less wrestling, and I didn’t have to kink the whip hose to do it. My wrist and the hose both thanked me.

On stubborn fittings—ones that hadn’t seen grease in a while—I pushed the gun to its high setting. The 10,000 psi rating isn’t marketing fluff; the coupler held steady without weeping or slipping. When the old, dry plug finally gave way, it did so without a sudden pop-off at the joint.

Sealing and pressure behavior

A right‑angle coupler lives or dies by its jaws and how well it seals while being pushed sideways. This one seals well if you take the extra second to align it squarely. Under pressure, you’ll feel a little resistance—normal for any coupler—as the jaw set tightens on the zerk. If you’re slightly cocked, you can get a thin ring of grease around the base. Back off, get square, and it settles down. I didn’t encounter any chronic leaking that suggested poor machining or a weak spring.

One practical tip: don’t bury the gun’s trigger at full blast as you’re seating the coupler. Pulse the trigger, verify you’re seated, then ramp up. The coupler will hold, but you’ll save yourself a mess.

Access and size tradeoffs

The body is compact, but not magic. On deeply recessed zerks—think narrow counterbores with minimal clearance—the head can still be a hair too bulky to bottom out. That’s the classic tradeoff: if you make the nose slimmer, you often compromise on jaw strength or sealing surface. Here, DeWalt leans toward durability. In day‑to‑day use, I’d call the size a net positive; it’s sturdy enough to lever against without feeling fragile. That said, I wouldn’t complain if the nose were a couple millimeters slimmer for those truly fussy recesses.

Compatibility notes

This is a zerk‑only tool. If your machine uses button‑head or flush‑type fittings, you’ll need the appropriate specialty coupler. With standard zerks, I had no compatibility surprises across automotive, agricultural, and outdoor power equipment fittings. The coupler doesn’t lock itself on—you need to keep a hand on it—so if you prefer hands‑free pumping on long runs, a dedicated lock‑on coupler might be more your style. For tight access, though, the lock‑on bodies are often too long; that’s where the right‑angle format wins.

It’s designed for cordless grease guns, and that’s how I used it. A manual gun will work too, but the bulk of a battery gun held off to the side really amplifies the benefit of the right‑angle head.

Durability and maintenance

After several weeks of regular use, the jaws still bite cleanly and release without sticking. I don’t see any deformation or slop developing at the angle joint. The finish wipes clean and hasn’t picked up more than superficial scuffs. As with all couplers, keeping the tip clean before snapping onto a zerk pays dividends: wipe the nose, expel a dab of grease to purge grit, and crack the gun’s relief to make removal easy after a high‑pressure shot. The 30‑day money‑back guarantee is a nice safety net if your use case ends up being edge‑case odd.

What could be better

- Nose diameter: A slightly slimmer nose would expand the number of recessed fittings it can reach. It’s already compact, but a bit less bulk at the tip would help on counterbored zerks.

- One‑hand retention: A lock‑on mechanism isn’t expected on a right‑angle coupler, but a light detent or improved knurling to help maintain grip when your hands are slick would be welcome. As it is, you need to support it at the joint while pumping at higher pressures.

- Clearer marking: Pressure rating is spec’d, but a small laser‑etched arrow indicating optimal approach orientation would help new users keep the jaws square when space is claustrophobic.

None of these are deal‑breakers, but they’re areas where a next revision could refine an already useful tool.

Who benefits most

- Mechanics dealing with driveline zerks, steering knuckles, and recessed chassis fittings.

- Landscapers and homeowners servicing mower deck spindles and idlers with limited overhead clearance.

- Operators of compact loaders, skid steers, and excavators where pin bosses are shrouded by structural steel.

If your grease points are all out in the open, a standard straight coupler is faster. If you routinely fight brackets and guards, this right‑angle head is the shortcut you’ve been missing.

The bottom line

The DeWalt right‑angle coupler solves a real access problem without introducing new headaches. It seals properly under high pressure, stands up to cordless‑gun output, and meaningfully reduces hose kinks and awkward wrist angles in tight quarters. It’s not the slimmest nose on the market, and you still need to hold it on the fitting, but those are reasonable compromises for a sturdy, compact right‑angle package.

Recommendation: I recommend this coupler for anyone who regularly faces recessed or obstructed grease fittings. It’s a reliable, high‑pressure attachment that turns “I can’t quite get on that zerk” into a routine task. If most of your fittings are easy to reach or you demand true hands‑free lock‑on operation, a standard lock‑on straight coupler may suit you better. For tight spaces, though, this right‑angle is the right tool.

Project Ideas

Business

Hard-to-Reach Lube Service

Offer a mobile lubrication service specializing in recessed and difficult zerks for fleets, ag equipment, and compact machinery. Use right-angle couplers to reduce disassembly time. Sell packages (monthly/quarterly) with documentation, photos, and post-service backpressure/flow notes.

Remote Grease Manifold Upgrades

Sell and install remote lubrication manifolds on skid steers, excavators, and conveyors. Bundle parts, hoses, and protective labeling, and include a one-time training on best practices using right-angle couplers. Market it as a downtime reducer with safer, faster PMs.

Weekend Grease Kit Rental

Rent a ready-to-go kit: cordless grease gun, right-angle coupler, flexible whip hose, cleaning caps, and a laminated quick-start guide. Add optional zerk mapping sheets for customer equipment. Great for homeowners’ associations, small contractors, and DIYers tackling seasonal maintenance.

Curated Lube Kits E‑commerce

Launch an online store offering tiered kits (Basic/Pro) featuring a right-angle coupler, quick-connects, spare jaws, seal kits, microfiber rags, scraper, and protective caps. Include a digital guide on identifying hidden zerks and avoiding over-greasing. Upsell with branded magnetic drip holders.

Hands-On Lubrication Workshops

Host paid workshops for small shops and vocational programs covering lubrication fundamentals, safe high-pressure practices, and techniques for servicing recessed zerks with right-angle couplers. Provide a certification of completion and sell tool bundles on-site.

Creative

Mobile Grease Gun Caddy

Build a compact, roll-around cart that docks a cordless grease gun and right-angle coupler. Include a drip tray, magnetic hose keepers, color-coded grease cartridges, an onboard charger, and a holster that protects the 90° coupler. Add a small LED work light and a clip-on rag holder so you can wheel the setup anywhere and service recessed zerks quickly.

Transparent Lube Flow Demo Block

Fabricate a clear acrylic block with embedded zerk fittings and machined channels that simulate bearings and bushings. Use dyed grease and the right-angle coupler to inject through different pathways and visualize flow, backpressure, and purging. Great as a teaching tool for apprentices or as a shop display.

Magnetic Drip-Catch Coupler Holder

Design and 3D-print a magnetic holder that the right-angle coupler snaps into between uses. Build in a replaceable absorbent pad and a small lip to catch excess grease. Mount it to a toolbox, lift post, or equipment frame to keep the coupler clean and ready without mess.

Lighted Mirror Clip for Hidden Zerks

Create a small, grease-resistant clip that mounts a low-profile LED and angled mirror alongside the coupler body. This lets you see recessed or rear-facing zerks while coupling at 90 degrees, reducing blind fumbling and cross-threading risk.

Remote Zerk Access Manifold

Build a custom manifold that relocates multiple recessed fittings to an accessible panel on a machine. Use short lines from each component to the manifold, then service them with the right-angle coupler in one place. Fabricate a labeled panel, protective guard, and quick-clean caps for a tidy, service-friendly upgrade.