Features

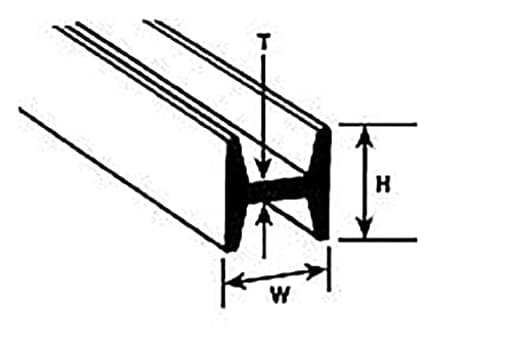

- Plastruct Styrene Structural H Columns - Pkg of 8, 1/8" H x 1/8" W x 15" L

- 1/8" H x 1/8" W x 15" L

Specifications

| Unit Count | 1 |

Related Tools

Pack of eight styrene H-shaped structural columns, each 1/8" high × 1/8" wide × 15" long. Designed for scale modeling and plastic construction to act as miniature H-beam columns for framing, reinforcement, or detailing; they can be cut, glued, and painted to fit project needs.

Plastruct HFS-4 H Column1/8 8 PLS90543 Plastic Building Supplies Review

Why I reached for these H-columns

On a recent industrial diorama build, I needed clean, repeatable structural members to frame a loading dock canopy and hint at the skeleton behind some corrugated cladding. I wanted something that would (a) read as steel in miniature, (b) stay straight over long runs, and (c) be easy to cut and bond without wrestling metal stock. The Plastruct H-columns checked those boxes, and after running through a full pack on that project, I’ve got a clear sense of where they shine and where you’ll want to plan around their limits.

What you actually get

This set includes eight styrene H-shaped columns, each 15 inches long with a 1/8-inch by 1/8-inch cross-section. In practical terms, that’s a nice balance: small enough to stay visually subtle, big enough to retain stiffness and presence. For scale reference:

- O scale (1:48): 1/8 inch scales to about a 6-inch flange, which reads like a substantial structural member for industrial and commercial scenes.

- HO scale (1:87): 1/8 inch scales to roughly 10.9 inches. It’s overscale for typical building columns but works well as heavy-duty beams, bridge components, or as a visual shorthand for robust steel framing.

- Larger scales (1:24, 1:12): it drops into the realm of light structural shapes, handrails, or architectural accents.

Eight lengths at 15 inches each gives you plenty of stock for test cuts, jigs, and the inevitable redo when a miter goes slightly off.

Material and dimensional consistency

These are extruded styrene, not ABS. My pack was remarkably consistent: crisp flange edges, uniform web thickness, and straightness that held up end-to-end. I measure a lot of modeling stock as a habit, and dimensional variance was negligible for a hobby application—good enough to build frames without chasing cumulative error. That’s a big deal if you’re assembling mirrored components or repetitive trusses; identical stock means your jigs can stay simple.

Styrene’s other advantage is predictability. It sands cleanly, scribes without fuzzing, and accepts solvent welding readily. The downside is heat sensitivity. Don’t leave long assembled runs in a hot car or under direct sun; styrene will telegraph thermal stress faster than brass or ABS.

Working properties: cutting, joining, and keeping it square

- Cutting: I got the best results with a razor saw and a miter box for accurate square cuts. You can score-and-snap across the flanges for shorter pieces, but the internal web resists a clean snap; I recommend a fine saw to preserve geometry.

- Mitering: For 45-degree joins, a bench-top miter jig is worth the setup. The H-shape wants to rock if you’re freehanding it, and tiny misalignments are obvious once painted.

- Drilling: If you need to run wire or pins through, use sharp bits and step up in sizes. Support the web to avoid ovalizing the hole.

- Solvent cements: Thin solvent welds (e.g., capillary types) wick beautifully into joints, especially where the flange meets a mating flat. For tack strength on tricky assemblies, I’ll sometimes dot a tiny CA glue pin at a hidden corner, then follow up with solvent for the final bond.

- Alignment: The H profile actually makes it easier to keep assemblies square. You can register a flange against a flat reference surface while the web aligns to a cross piece. I built a quick right-angle jig from scrap MDF and packing tape; it sped things up and reduced cleanup.

Strength and stability in miniature

You’re not building a real bridge, but in miniature, stiffness matters. Oriented vertically as a column, these feel rigid for their size. As beams, they carry their own weight and then some over moderate spans, especially if you orient the web to resist visible deflection. Don’t expect them to stay arrow-straight over a 12-inch unsupported span with added loads; if you’re hanging detail or lighting, build in intermediate supports or box the section with additional styrene.

One performance note: the H shape gives you a lot of glueable surface area without adding bulk. When I laminated a flange to a flat wall panel, the bond was rock solid with minimal squeeze-out, and the joint line all but disappeared under primer.

Finishing and paint behavior

Styrene is forgiving. I lightly sanded the factory sheen with 600–800 grit, hit everything with a plastic-compatible primer, and painted with acrylics. No fisheyes, no adhesion drama. The crisp corners hold dry-brushed highlights nicely, and the recesses along the web are perfect for capillary panel line washes. If you’re weathering for a steel look, a dark gray base with a graphite rub on the flanges reads convincingly metallic without metallic paint.

Two finishing cautions:

- Pooling: The H recess can trap excess primer or wash; wick it out before it dries to avoid soft edges.

- Solvent overdo: Heavy lacquer passes can soften styrene edges. A couple of light coats beat one wet one.

Scale realism and visual read

Are these exact replicas of a particular structural steel profile? Not to an engineering spec, but the proportions are close enough that, on a finished model, they read as steel. The flange-to-web relationship looks right to the eye, which matters more than micrometer-level accuracy in most display contexts. In HO, I treat them as overbuilt—but that’s often the goal when you want a scene to feel industrial. In O, they’re spot-on for robust commercial frames.

Use cases I found most effective

- Framing and trusses: Ideal as primary members in small gantries, loading dock frames, trackside structures, and shed supports.

- View-blocking structure: Behind windows or translucent panels, the H silhouette reads cleanly and gives depth without needing full interior builds.

- Jig building: Because it’s straight and predictable, I’ve used offcuts as temporary guides for assembling other styrene shapes squarely.

- Detailing: Short lengths make convincing stiffeners along bridge girders or crane booms.

Comparisons and alternatives

- Brass H-section: Brass is tougher, more heat-resistant, and can carry real loads in RC or functional builds. It’s harder to cut and soldering adds complexity. I reach for brass when durability trumps ease of use.

- ABS shapes: Slightly tougher than styrene and less prone to solvent damage, but gluing can be less straightforward depending on your cements.

- 3D-printed beams: Great for custom profiles, but layer lines and straightness over long runs can be challenging, and they typically require more finishing.

For pure scratch-building productivity—cut, glue, paint, done—these Plastruct H-columns hit the sweet spot.

Quibbles and gotchas

- Length management: At 15 inches, they’re long enough to pick up minor bends if stored loose. Keep them in a rigid tube or clipped flat to a board.

- Heat sensitivity: Don’t prime or paint with hot solvents in a single heavy pass; you can soften flanges.

- Internal cleanup: The inner corners of the H are hard to sand if you get a glue blob in there. Apply solvent sparingly and from the outside face whenever possible.

None of these are dealbreakers; they’re part of working with styrene.

Value and coverage

With eight sticks per pack, you get ample material for a small structure or several detailed subassemblies. I built a canopy frame, a set of interior columns, and still had offcuts left for jigs and future projects. The uniformity means almost every inch is usable; you’re not culling warped pieces.

Bottom line

If you build in plastic and need a reliable, believable stand-in for steel framing, these H-columns are easy to recommend. They’re straight, consistent, and behave exactly like good styrene should: cut cleanly, bond quickly with solvent cements, and take paint without fuss. While brass or ABS may be better for high-heat or high-stress applications, for most diorama, railroad, and architectural scratch builds, these deliver a fast path to clean, structural-looking results.

Recommendation: I recommend the Plastruct H-columns. They offer consistent dimensions, excellent workability, and a versatile size that adapts across multiple scales. As long as you respect styrene’s heat limits and store the long lengths carefully, they’ll reward you with crisp assemblies and a professional finish with minimal rework.

Project Ideas

Business

Architectural Model Kit Line

Assemble and sell DIY kits that include pre-cut H-columns, connector pieces, cladding sheets, and illustrated assembly guides for common building types (modern tower, factory shell, parking structure). Offer tiered kits (beginner to pro) and scaled options for architects, students, and hobbyists. Market via architecture schools, Etsy, and LinkedIn; price kits based on parts complexity and finished size.

Gaming & Terrain Pack Product

Create ready-to-use industrial scenery packs for wargamers and model railroaders: themed bundles containing cut H-columns, painted/primed support frames, ladders, rails, and step-by-step terrain assembly instructions. Offer expansions (collapsed ruin, refinery module) and digital templates for customization. Sell on hobby platforms and partner with local gaming stores for demos.

Workshops and Online Classes

Run hands-on workshops teaching model framing, scratch-building, and weathering using styrene H-columns. Complement in-person sessions with paid video courses, downloadable cut lists, and printable jig templates. Upsell pre-cut material packs and branded tool kits. Partner with makerspaces and community colleges to reach students and hobbyists.

Custom Prototyping & Scale Framing Service

Offer a service building small structural mockups and display frameworks for architects, product designers, and prop departments. Use the H-columns as standardized modular pieces for quick-turn models, optionally finishing them to client specs (paint, baseboard, lighting). Charge per hour plus materials, and promote through architecture firms, design agencies, and online freelancer marketplaces.

Creative

Miniature Skyscraper Skeletons

Use the H-columns as the internal frame for scale architectural models. Cut the 15" lengths into various column heights, glue into orthogonal grids to mimic H-beam steel framing, then skin with thin foamboard or styrene sheet to create realistic high-rises. Tips: mark a scale (1:87, 1:144), pre-cut connector blocks from scrap styrene for rigid joints, and finish with metallic paint and weathering washes for realism. Great for diorama centers, model train cityscapes, or portfolio pieces.

Industrial Diorama Scaffolding & Catwalks

Build believable factory/ruin interiors by using the H-columns as vertical supports for scaffolds, catwalks, and elevated platforms. Combine with thin styrene strip for walkways, micro-railings, brass rod for pipes, and tacked-on mesh for grated floors. Add ladders and hoist points from wire to increase detail. Weathering with rust pigments and dry-brushing turns them into convincing gaming terrain or display bases.

Modern Geometric Wall Sculptures / Mobiles

Exploit the clean H profile to create lightweight geometric art. Cut columns into short sticks, glue them into repeating lattice patterns or concentric frames, paint in complementary colors or metallics, and suspend as mobiles or mount on a narrow board as minimalist wall art. Vary lengths and orientations to produce interesting shadows and negative space.

Jewelry & Desk Organizers

Turn the H-columns into small functional objects: T-bar necklace stands, earring racks, mini shelving for desk supplies, or pen holders. Bond multiple pieces at right angles for multi-tier organizers and mount on small wooden or acrylic bases. Finish with sanding, sealing, and paint or rub-on metal finishes for an upscale look — perfect as gifts or craft-fair items.