Features

- Perfect for use on farm or industrial equipment such as tractors, trailers, lawn mowers and other implements

- Rust preventative formula protects items from wear and provides excellent coverage

- Dries to the touch in 2-4 hours and covers up to 130 sq. ft. per quart

- Heavy-duty paint is ultra durable and resists chipping and weather damage; the ideal tractor paint for any conditions

- Gloss finish matches to original equipment manufacturer colors

Specifications

| Color | Black |

| Size | Quart (Pack of 1) |

| Unit Count | 1 |

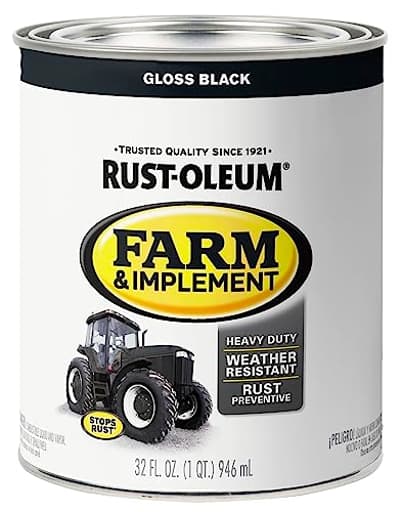

Gloss black enamel paint formulated for farm and industrial equipment such as tractors, trailers, and lawn mowers. The rust-preventative, heavy-duty formula resists chipping and weathering, dries to the touch in 2–4 hours, and covers up to about 130 sq ft per quart while matching OEM gloss finishes.

Rust-Oleum 280104 Farm & Implement Enamel Paint, Quart, Gloss Black, Review

What it is and where it shines

Rust-Oleum’s Farm & Implement Enamel in gloss black is a straightforward, oil-based finish built for metal that lives outdoors: tractor frames, implements, mower decks and chassis, utility trailers, gates, and shop fixtures. It’s a heavy-bodied enamel with rust-inhibiting chemistry that’s meant to brush, roll, or spray well, lay down to a high-gloss finish, and stand up to bumps, sun, and weather. In practice, it behaves like a more durable, slower-curing version of a typical oil enamel, with better self-leveling and toughness than budget paints.

I’ve used this quart on a utility trailer tongue and frame, a UTV footwell and rails, a mower’s chassis plates and PTO guard, and a handful of shop jigs and clamps that live in a damp barn. Across those projects, the common thread was consistent: it covers well, it goes on forgivingly, and once it’s fully cured, it resists chipping better than most general-purpose enamels I’ve used.

Prep matters (and the paint rewards it)

I got the best results with sensible metal prep:

- Degrease thoroughly. I used a solvent degreaser followed by a clean mineral spirits wipe to remove oil and silicone residues.

- Remove rust scale. A wire cup on a grinder and some hand sanding got me to tight, sound metal. For heavy pitting, I hit spots with a rust-converting primer and let it cure before topcoating.

- Scuff glossy old paint. A quick 180–220 grit scuff was enough to give the enamel teeth.

On lightly rusted or previously painted surfaces, the enamel bonded well without a separate primer. On bare steel that will live outside year-round, a compatible rust-inhibitive primer underneath extended the protection and seemed to improve chip resistance at sharp edges. The gloss finish is reflective and will highlight surface imperfections, so a little extra time with filler and sanding pays off if appearance matters.

Application: brush, roll, or spray

The paint is thick enough to hang on verticals yet still self-level, which makes brushing painless. I had the cleanest results with:

- Brush: A good natural bristle or china-bristle brush and a steady, wet edge. Don’t over-brush; this enamel smooths itself out if you lay it and leave it.

- Roller: A 4” high-density foam roller is great for flat rails and panels. I tip off with a brush where needed. Roll-and-tip eliminated almost all texture for me.

- Spray: For larger surfaces, I sprayed with an HVLP gun after thinning modestly with mineral spirits per the can guidance. Two medium-wet coats 10–15 minutes apart produced a uniform gloss. If you spray, strain the paint first; pigments settle, and straining avoids tip spitting.

Stir thoroughly. The pigment load is high, and a few minutes of mixing brings the consistency from syrupy to smooth and uniform. If the can’s been sitting, I stir, rest, then stir again.

Dry time and the recoat window

At roughly 70°F and low humidity, I consistently saw “dry to the touch” in about three hours. I could handle parts gently by evening and recoat the next day without issues. Like most alkyd enamels, this paint has a recoat window—check the label and stick with it. My rule here: if I miss the early recoat window, I wait until the next day (or longer if conditions are cool), then scuff lightly before adding another coat. The enamel continues to harden over several days. It’s noticeably tougher after a full week, especially in cooler shops.

If you need maximum hardness and a faster return to service, an enamel hardener (compatible with oil/alkyd systems) does make a difference. I’ve used it on parts that see abrasion, and it speeds cure and increases scratch resistance. Test on a small piece first and follow the hardener’s ratios—over-activating can make the finish brittle.

Finish quality and color match

This is a true gloss black with a deep, wet look once it levels. On my trailer frame and mower chassis plates, the sheen matched existing OEM gloss black components closely—no odd brown or blue cast under sunlight. Two coats gave me full, even coverage. Edge retention is good for an oil enamel; it doesn’t shrink back from corners the way thinner paints can.

As with all high-gloss blacks, surface prep dictates how “factory” it looks. Any sanding scratches or grinder marks will telegraph. If you want that showroom gloss on flat panels, a final pass with 320 grit and a tack cloth before paint pays off, and avoid painting in direct sun, which can flash the solvents too quickly and leave texture.

Durability in the real world

I consider chip resistance the litmus test for implement paints. After a few months of field use:

- Trailer: Chains, hooks, and ratchet straps hitting the tongue left minor scuffs but no flaking. The enamel compressed rather than chipping through to bare steel, which is exactly what I want outdoors.

- UTV footwell rails: Boots and gravel brought some micro-scratches, but the film stayed intact and cleaned up to a uniform gloss with a wipe-down.

- Mower chassis plates and PTO guard: No lifting near fasteners after reassembly. Where I primed bare steel first, edges stayed better protected from nicks.

UV exposure hasn’t dulled the gloss so far. Black will show dust and pollen, of course, but the surface wipes clean. In a damp barn, I’ve had no underfilm rust creep at stone chips—another sign the rust-inhibitive package is doing its job.

Coverage and value

Rust-Oleum rates coverage up to about 130 square feet per quart. My real-world numbers:

- Over scuffed, previously painted surfaces: roughly 120–130 sq ft per quart per coat.

- Over bare or pitted steel: closer to 90–110 sq ft per quart per coat.

That’s with a mix of brush and roll. It’s an efficient coating for the film build you get, and two coats have been sufficient for me on everything but heavily pitted steel, which sometimes benefits from a third thin coat.

What I’d improve

- Cure speed: It’s not slow for an oil enamel, but if you’re used to waterborne or catalyzed coatings, plan for the longer cure time. Full hardness takes days, not hours.

- Solvent odor and VOCs: This is an outdoor or very well-ventilated shop paint. A respirator with organic vapor cartridges is a must when spraying.

- Recoat sensitivity: Like many alkyds, you need to respect the recoat window. If you rush or miss it badly, you risk wrinkling. Build a little schedule buffer into your project.

- High-gloss honesty: The gloss is a feature, but it demands good prep. If you’re trying to hide grinder marks, a satin sheen would be more forgiving (this product is gloss-only in this color).

Practical tips for better results

- Temperature and humidity: I aim for 60–80°F, moderate humidity. Cold, damp days slow cure and invite gloss irregularities.

- Edges and fasteners: Feather and round sharp edges with a file or sandpaper. Thin films chip at knife edges; a small radius holds paint better.

- Strain before spray: A simple paint strainer saves headaches.

- Avoid heavy coats: Two medium coats beat one heavy one. You’ll reduce sags and speed cure.

- Hardware timeout: If you’re reassembling painted parts, waiting 48–72 hours before tightening bolts helps avoid marring the finish.

Who it’s for

- Owners restoring or maintaining tractors, implements, trailers, and metal yard equipment who want an OEM-like gloss black that’s tougher than general-purpose enamel.

- DIYers who prefer the flexibility to brush, roll, or spray from a quart without jumping to a full automotive system.

- Shops needing a dependable rust-preventive topcoat for non-heat-exposed metal work.

It’s less ideal if you need ultra-fast turnaround, ultra-low odor, or a satin/flat sheen. It’s also not a high-heat coating—skip exhausts or engine manifolds.

Recommendation

I recommend Rust-Oleum’s Farm & Implement Enamel in gloss black for equipment and outdoor metal work where durability, coverage, and an OEM-like gloss matter more than rapid cure time. It rewards competent prep with a smooth, deep finish that holds up to abrasion and weather, and it applies well by brush, roller, or spray. If you can give it adequate ventilation and a few days to harden, it’s a reliable, cost-effective way to refresh and protect black metal parts that earn their keep outside.

Project Ideas

Business

Mobile Farm Equipment Touch-Up Service

Offer on-site touch-up and small repaint jobs for tractors, trailers and implements. Market the service to local farms and equipment dealers, using the OEM-matching gloss enamel to repair scratches, cover rust spots, and maintain resale value. The quart size and fast drying allow efficient, low-overhead jobs between seasons.

Custom Metal Furniture Line

Build and sell a line of industrial outdoor furniture (tables, benches, planters) finished with heavy-duty gloss enamel. Emphasize weather resistance and durable finish in product listings and offer customization (matte vs. gloss, added distressing). Target farmhouse decor markets and garden centers.

Restoration & Detailing Shop

Start a small shop specializing in cosmetic restoration of vintage implements, lawn tractors and small trailers. Use the rust-preventative enamel for OEM-style finishes, package restoration work with parts cleaning, rust treatment, and decal replacement to charge premium rates.

OEM Touch-Up Paint Kits

Create and sell touch-up kits for common farm equipment colors that include a quart of enamel, brushes/foam applicators, prep wipes and simple instructions. Offer local pickup or ship nationally; market to DIY farmers and small repair shops who want an authentic, durable finish.

Contract Work for Local Fleets

Contract with landscaping companies, municipal parks, or small haulers to maintain the paint on trailers and equipment. The product’s chipping and weather resistance reduces fleet downtime and appearance upkeep; offer scheduled maintenance packages to secure recurring revenue.

Creative

Vintage Tractor Accent Table

Upcycle an old tractor seat and metal parts into a small side table. Clean and sand the metal, apply the gloss black enamel as a durable base coat (its rust-preventative formula helps outdoor longevity), then seal with a clear topcoat if needed. The OEM-matching gloss gives an authentic, industrial look that holds up on a covered porch or in a workshop.

Weatherproof Metal Planters

Transform salvaged metal drums, buckets or feed troughs into sleek black planters. Use the heavy-duty enamel to coat interiors and exteriors (after addressing drainage and lining if needed). The paint resists chipping and weathering, keeping planters looking crisp season after season.

Restored Tool Chest Makeover

Refinish a scratched or rusty metal tool chest with this gloss enamel to give it an OEM-style finish. Prep with degreaser and light sanding, then apply thin, even coats for full coverage. The fast dry time (2–4 hours) means a weekend project with professional-looking results.

Blackout Signage & Stenciled Art

Use the gloss black as a background for custom metal signs or stenciled house numbers. Its smooth gloss finish provides strong contrast for metallic or white lettering. Because it adheres well to metal and resists weathering, signs stay sharp outdoors.

Outdoor Metal Furniture Refresh

Revive wrought-iron chairs, metal benches or lawnmower frames with a durable glossy coat. The enamel’s rust-preventative properties protect joints and moving parts; the gloss finish hides previous blemishes and creates a cohesive, factory-like appearance.