Features

- Centers multiple cables on framing members

- Offers convenient space management and aids in identification

- Features durable plastic construction

- RoHS 2011/65/EU Compliant

- For industrial/occupational use only. Not for consumer sale or use

Specifications

| Color | White |

| Size | 3.84 in x 1.19 in |

| Unit Count | 1 |

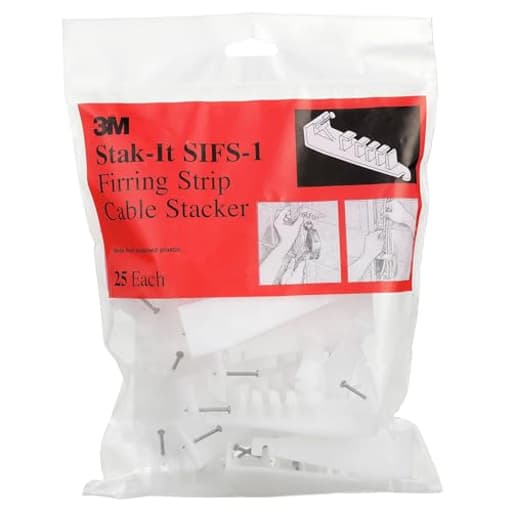

A plastic cable stacker designed to center multiple electrical cables on framing members, providing organized spacing and aiding identification. Measures 3.84 in x 1.19 in, is UL listed, NEC compliant, RoHS 2011/65/EU compliant, and intended for industrial/occupational use only (not for consumer sale or use).

3M Furring Strip Cable Stacker SIFS-1, Stak-It, Electrical Wire Spacer and Support for Specialty Use, UL Listed, NEC Compliant Review

I’ve spent enough hours chasing unruly Romex across open studs to appreciate a simple fix that keeps cable runs neat, centered, and compliant. The Stak-It SIFS-1 cable stacker from 3M has become one of those small, reliable pieces of plastic that quietly improves my workflow, especially on jobs with mixed low-voltage and NM-B runs.

What it is and why it matters

The Stak-It is a compact plastic cable stacker that mounts to framing and organizes multiple cables in individual channels while keeping them centered on the stud or joist. It’s UL listed, NEC compliant, and RoHS compliant—boxes I want checked before an inspector shows up. The footprint is small (roughly 3.84 x 1.19 in), and the profile is low enough to tuck into busy stud bays without getting in the way of boxes or bridging.

Why center cables? Two reasons: protection and consistency. Centering maintains the 1-1/4 in setback from stud faces so screws and nails have less chance of nicking a cable when drywall goes up. It also keeps runs parallel, separated, and easier to label and trace—hugely helpful for troubleshooting later or leaving a clean project behind for the next person.

Design and build

The Stak-It is molded from durable plastic with parallel channels that stack cables in layers. It doesn’t latch over the cable; instead, each compartment grips just enough to hold the wire in place without crimping. I prefer that light friction fit because I can slide conductors to adjust slack or re-route order without fighting a clip. Once there are a few cables in, they sit snug.

The angled nailing approach is thoughtful. Driving the fastener at about 45 degrees lets me install these where a hammer swing would otherwise be awkward—tight against a top plate, under a joist, or beside a crowded box. In areas where nails aren’t ideal (existing masonry, steel studs, or delicate finishes), I’ve had no trouble substituting screws through the body, as long as I’m mindful not to crack the plastic by over-torquing.

The white color sounds like a minor detail, but it makes visual identification easier when I’m mapping paths in a dim basement or crawl space. Labels on the cables combined with the consistent layout these create make later service genuinely easier.

Capacity and cable types

This stacker is more versatile than it looks. I routinely use it with:

- NM-B 14/2, 12/2, and 12/3

- RG6 coax

- Cat5e/Cat6 data cable

- 14-gauge speaker cable (2- and 4-conductor)

Capacity depends on the mix. With typical residential loads, I’ll run one cable per slot for NM and double or triple up lighter-gauge low-voltage lines. The ability to layer several channels vertically means I can handle six to eight conductors in one spot without a tangle. If I’m stacking a lot of thicker cables (for example, multiple 12/2s plus a couple of RG6), I space stackers every 2–3 feet to keep the bundle orderly.

A quick compliance note: while the Stak-It is NEC compliant, you still need to follow derating and bundling rules. These keep conductors separated enough to promote airflow (better than tightly taped bundles), but if you’re running multiple current-carrying conductors together for long stretches, check your ampacity adjustments. The whole point of these is to organize and center, not to encourage tight bundling.

Installation: small details that add up

My best results come from staging a few stackers before pulling cable. I’ll anchor two or three along a planned path, pull the conductors, lay them into channels, then add more stackers as the route develops. Because the compartments don’t lock, I can shift positions, add another run, or re-sequence without starting over—handy when a late change order sends another circuit down the same bay.

At turns, terminations, and box entries, I still secure the cables with staples or straps as required. The Stak-It isn’t designed to be the only mechanical support—think of it as a spacer and organizer that keeps your primary fasteners cleanly aligned. It does, however, reduce how many staples I need overall, and it absolutely reduces rework from prematurely stapling a cable only to discover another run needs to pass behind it.

On joists, the Stak-It works just as well as on wall studs. It’s particularly useful for long, straight runs across a basement ceiling where I want even spacing and clear air around the cables. In open-ceiling workshops where a vacuum system, lighting, and dedicated circuits share spans, these keep everything tidy and easy to follow.

Jobsite performance

The standout benefit is time saved. Instead of wrestling a growing bundle with individual staples, I can drop in the stacker, place each cable in a channel, and rake the run straight in seconds. Neatness isn’t just aesthetics—it prevents twist and sag that make future pulls harder and complicate identification.

Heat management is a quiet win here, too. By keeping conductors from pressing hard against each other, the Stak-It promotes a bit of air around each cable. That’s not a license to ignore derating rules, but in open bays it’s a smarter approach than compressing cables with tape or zip ties.

I’ve whacked these with 2x material, knocked them with a ladder, and dragged cable through them without cracking one. If I misplace one, removal takes a little care; they’re reusable, but I don’t count on getting every single one out pristine if I’ve driven the nail deep.

Comparisons and cost

Against traditional staples, the Stak-It wins in speed and organization when three or more cables share a path. For one or two cables on a short hop, staples remain the most economical and arguably faster. For dense low-voltage hubs, I’ll sometimes use screw-mount zip-tie bases, but those don’t maintain centerline clearance the way these do.

Compared with latch-style stackers, the 3M design trades positive retention for adjustability. I’ve never had a cable pop out during normal work, but if you yank a run sideways before it’s fully supported, the cable will slide. In practice, I just add a staple or a second stacker near transitions, and it’s a non-issue.

Price-wise, outfitting an entire house exclusively with stackers would add up, so I target them where they matter: near panels, over and under boxes where many cables converge, along exposed runs I want to showcase, and anywhere swing space is limited. That strategy offers most of the benefit without ballooning material costs.

Compliance and inspection

This is an area where the Stak-It quietly shines. UL listing and NEC compliance aside, inspectors like seeing centered conductors, clean separation, and thoughtful support. The stacker inherently places cables where they should be—away from screw danger zones—so I’m not measuring offsets or adding nail plates as often. It reduces the little gotchas that slow down sign-off.

One note: 3M designates this for industrial/occupational use. That fits how I use it—on professional installations where compliance, traceability, and consistent layout matter. If you’re not trained for electrical work, consult a licensed electrician and follow local code.

What I’d change

- Cost could be lower for bulk use, though the labor savings can offset it in many situations.

- A tiny chamfer or clip on the entry edges might make it even easier to snap in stiffer NM in cold weather.

- Color options would be nice for quick visual grouping (line-voltage vs low-voltage), but labels do the job.

These are minor quibbles. Functionally, the tool is dialed-in for what it’s meant to do.

The bottom line

The 3M Stak-It SIFS-1 cable stacker is a smart, durable organizer that keeps multi-cable runs centered, clean, and compliant. It doesn’t replace staples or straps, but it makes everything around them faster and better. I reach for it any time three or more cables share a path, when I’m working in tight spaces where a hammer swing is limited, and anywhere a neat, serviceable installation matters.

Recommendation: I recommend the Stak-It for professional electricians and experienced installers who want consistent spacing, easier inspections, and cleaner cable management on wood framing. Use it strategically—converging runs, long exposed spans, and busy stud bays—and it earns back its cost in saved time and fewer reworks while delivering a tidy, compliant finish.

Project Ideas

Business

Contractor Supply Packs

Assemble and sell branded packs of UL-listed stackers to electrical contractors and framers, bundled with color-coded ID tags and installation guides that emphasize NEC compliance. Market as time-saving kit for new builds and remodels.

Pre-Staged Wiring Service

Offer a service for builders and MEP firms to pre-stage and organize multiple cable runs on framing using stackers before final electrician hookup. Position the service as a labor-saver that reduces install time for licensed electricians and improves inspection readiness.

Professional Training Courses

Develop short certification workshops for apprentices and foremen that teach best practices in cable centering, spacing, and identification using the stacker. Charge per attendee and provide take-home starter kits (stackers + labeling materials).

Labeling & Documentation Package

Package the stacker with a digital documentation service: on-site cable photos, labeled diagrams, and a cloud-stored baseline for maintenance. Sell as a maintenance-ready solution to facilities managers who need clear cable identification and traceability.

Event & AV Rental Kits

Create rental kits for event production and AV companies that include stackers, color-coded cable sleeves, and quick guides for organized temporary installs. Market to production houses and rigging companies that must rapidly deploy tidy, inspectable cable runs.

Creative

Apprentice Training Jig

Build a portable framing mock-up that uses the stacker to teach apprentices how to center and space multiple cables on studs. Use de-energized or blank cable mock-ups so trainees can practice routing, labeling, and consistent spacing in a safe, controlled environment.

Shop Logo Cable Mural

Design an industrial-style wall mural in your workshop or break area by arranging colored cables through multiple stackers to form a company logo or graphic. The stackers keep bundles neat and evenly spaced on the framing, giving a clean, engineered look appropriate for a tradespace.

Trade-Show Demo Panel

Create a quick-assembly demo panel for trade shows that shows before/after cable management and identification. Use the stacker to demonstrate consistent spacing, identification techniques, and UL/NEC-compliant products — useful for marketing and salesperson demos to contractors and facility managers.

Modular Low-Voltage Run Organizer

For set designers or AV shops working with licensed pros, use stackers to keep multiple low-voltage runs (data, speaker, control) centered on temporary framing. The stacker makes repetitive rig builds tidy and repeatable without altering permanent structure.

Workshop Cord & Hose Rack

Repurpose stackers as spacers on a wall-mounted board to organize extension cords, air hoses, and tool leads. The durable plastic keeps runs separated and visible for quick identification and storage in an industrial shop environment.