Features

- Aluminum oxide abrasive for cutting

- Proprietary material mix intended to extend wheel life

- Two full sheets of fiberglass reinforcement for durability and safety

- Available in abrasive grades A36T (faster/aggressive cutting) and A60T (cleaner, longer life)

- Thickness options: 0.035" and 1/16" for cutting; 1/8" for peripheral grinding

Specifications

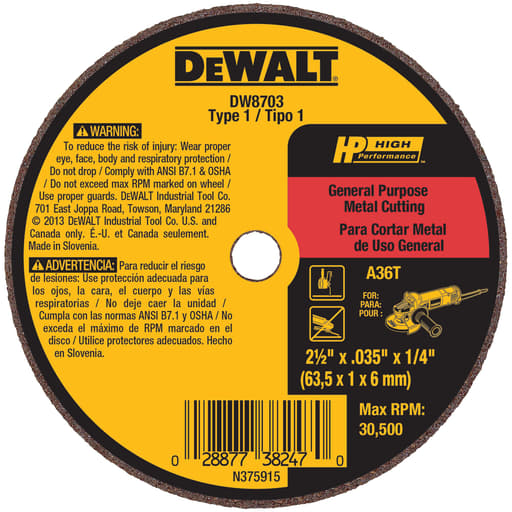

| Disc Type | Type 1 (die grinder/cutoff wheel) |

| Disc Diameter In | 2-1/2 |

| Disc Thickness In | 0.035 in |

| Product Diameter In | 2-1/2 in |

| Number Of Pieces | 50 per pack |

| Abrasive Grades | A36T; A60T |

| Intended Materials | Ferrous metals and stainless steel |

Related Tools

Related Articles

Type 1 die grinder/cutoff wheels intended for cutting and peripheral grinding of ferrous metals and stainless steel. Constructed with aluminum oxide abrasive and a proprietary material mix, and reinforced with two full sheets of fiberglass for strength and safety.

DeWalt 2-1/2 in x .035 in x 1/4 in Die Grinder Wheels (Type 1) Review

Why I reached for these 2-1/2-inch cutoffs

Tight quarters are where small die grinder wheels shine, and that’s exactly where the DW8703 wheels earned their spot in my kit. Think trimming a welded bracket inside a frame rail, nipping a seized bolt flush, or making a relief cut on a stainless clamp where a 4-1/2-inch grinder simply doesn’t fit. In those moments, a thin Type 1 wheel on a die grinder is the right tool—and these DeWalt wheels feel purpose-built for that niche.

Build and specs that matter in use

The DW8703 wheels are Type 1 (flat) die grinder cutoffs with a 2-1/2-inch diameter, a 0.035-inch kerf, and a 1/4-inch arbor hole to run on a mandrel. The wheel uses aluminum oxide grain in a proprietary bond, and it’s reinforced with two full sheets of fiberglass. On paper, that reads as standard fare; in hand, the reinforcement is immediately noticeable. The wheels are rigid enough to track true under light pressure without that wobbly, harmonics-prone feel cheaper discs sometimes have.

They’re part of a small family: two abrasive grades (A36T for faster, more aggressive cutting; A60T for cleaner edges and longer life) and thickness options geared to use-case—0.035 and 1/16 inch for cutting, and 1/8 inch for peripheral grinding. My testing focused on the 0.035-inch A36T and A60T wheels, with occasional swaps to the 1/16-inch version for durability checks.

Setup and compatibility

These wheels are designed for ferrous metals and stainless. I’ve had good results on mild steel plate up to 3/16 inch, angle, threaded rod, and 304 stainless brackets. They’re not intended for aluminum or copper—aluminum oxide will load quickly on soft non-ferrous stock—so keep a dedicated non-loading disc for those.

Mounting is straightforward: use a quality 1/4-inch arbor mandrel with a 1/4-inch shank that fits your die grinder collet. Make sure the flanges sandwich enough surface to keep the wheel flat and centered, and verify your grinder’s free speed doesn’t exceed the wheel’s printed maximum RPM. If your die grinder supports a cut-off guard, use it. On unguarded bodies, I position the tool so the wheel throws sparks away and can’t climb toward me if it binds.

Cutting performance

Start-up and tracking: The wheels spin up cleanly with minimal flutter. On a straight or right-angle die grinder, they track accurately along a scribed line without wander. That’s where the fiberglass layers pay off; there’s a “planted” feel even at full speed.

Speed vs. pressure: They like full RPM and light, steady pressure. Pushing harder doesn’t noticeably speed the cut; it just heats the kerf and eats the wheel. With light pressure, the A36T grade in particular throws a consistent stream of fine sparks and moves quickly through 1/8-inch mild steel.

Cut depth reality: At 2-1/2 inches, you’re not chasing deep cuts. For anything thicker than about 3/16-inch plate or larger diameter tube, I make score passes and flip the work if possible. If you routinely need deeper reach, a 3-inch wheel is the more practical size.

A36T vs. A60T: choosing the right grade

A36T (coarser, “T” hardness): My choice for quick sectioning of mild steel fasteners, small brackets, and rusty hardware. It bites faster and clears debris well. The tradeoff is slightly rougher edges and marginally shorter life.

A60T (finer, same hardness): Better for stainless and any cut where I care about finish and heat input. It runs a touch slower but leaves a cleaner edge with less burr and less chance of blueing thin stainless. Life per wheel is noticeably longer in the same material.

Both grades feel stable; neither smears or glazes prematurely if you keep pressure reasonable.

Durability and life

The proprietary bond here hits a useful middle ground. These are not ceramic-grain “hot rod” wheels, but they hold diameter respectably and resist chunking at the edge if you avoid side loading. On repetitive work—short cuts on 1/8-inch stock—I can make multiple clean passes before I notice a step down in cutting speed. The 1/16-inch variant lasts longer when cuts are less delicate and access allows a slightly thicker kerf.

Abuse tolerance is typical of a thin Type 1 wheel: bind the kerf or twist the grinder and any disc can fracture. The fiberglass layering gives a margin of safety, but technique still matters. If you need to lean on the wheel laterally or do any meaningful edge chamfering, the 1/8-inch peripheral grinding option is the safer pick.

Cut quality and heat

With the 0.035-inch kerf, cuts are crisp and narrow. On mild steel, burr formation is modest and easy to knock down with a quick pass of a file or a flap wheel. On stainless, the A60T grade helps keep heat in check; I still pause occasionally to let the work cool when trimming thin gauge stainless to avoid discoloration.

The spark stream is fine and predictable, and the bond sheds abrasive smoothly instead of shedding chunky grit. That translates to fewer micro-hops as you reach the end of a cut.

Safety, technique, and best results

A few habits that paid off with these wheels:

- Let the wheel do the work; use light, steady pressure.

- Square the wheel to the cut and avoid side loading.

- Score first on thicker material, then deepen the groove rather than trying to plunge to full depth.

- Clamp the work. Thin wheels hate movement in the kerf.

- Keep the wheel shank and mandrel tight, and recheck after the first few cuts.

- Always confirm the wheel’s max RPM; most die grinders spin fast.

I also like to start a cut slightly away from the final line, then come back for a final, light pass. The wheels are thin enough that this approach leaves a cleaner edge and reduces the chance of pinching as the waste drops.

Comparisons and value

Against premium ceramic-grain small wheels (think high-end industrial discs), these DeWalt wheels cut a bit slower but cost significantly less per piece, especially in the 50-pack. Compared to generic import wheels, they track truer, shed less unpredictably, and last longer in stainless. In tight quarters, consistency counts more than headline speed, and that’s where they earn their keep.

If you primarily cut heavy cross-sections or need deeper reach, a larger diameter or a ceramic-grain wheel will outperform them. For aluminum, reach for a dedicated non-loading disc; these are for ferrous and stainless.

Who they’re for

- Fabricators and mechanics who need to make accurate cuts in confined spaces.

- Anyone working on chassis brackets, exhaust hangers, small fasteners, or stainless trim where a 4-1/2-inch grinder is too big.

- Users who value a reliable, predictable wheel with clear grade choices (A36T for speed, A60T for finish and life).

If you want to use a die grinder wheel as a general-purpose grinder, step up to the 1/8-inch peripheral grinding option; thin Type 1 wheels are for cutting, not lateral grinding.

Final recommendation

I recommend the DW8703 wheels for tight-access cutting on ferrous metals and stainless. They track true, cut predictably at full die grinder speed, and offer sensible choices between aggressive (A36T) and cleaner, longer-running (A60T) performance. The two-layer fiberglass reinforcement adds confidence without making the wheel feel stiff or grabby, and the 50-pack delivers consistent results at a fair cost per cut. They do demand a steady hand and proper technique—as all thin Type 1 wheels do—and they’re not a solution for non-ferrous materials or deep cuts. But used as intended, they’re a dependable, compact cutting option I’m happy to keep within reach.

Project Ideas

Business

On-Demand Bracket & Tab Micro-Fab

Offer a same-day service making small steel/stainless brackets, tabs, shims, and spacers for contractors, HVAC techs, and auto shops. Use A36T wheels for fast cuts and A60T for clean finish edges. Price by piece and thickness, and provide a small catalog of common shapes.

Commercial Kitchen Stainless Customization

Provide on-site modification of stainless shelves, prep tables, racks, and guards: trimming lengths, adding notches for pipes, and fitting equipment. The compact 2-1/2 in wheels are ideal for tight spaces. Sell service contracts to restaurants and caterers for recurring adjustments.

Industrial Home Decor Shop

Launch an online store for minimalist metal decor: coat racks from upcycled tools, bookends from angle iron, geometric wall art, and custom nameplates cut from thin steel. The A60T wheels deliver clean cuts that reduce finishing time, improving margins on small-batch items.

Mobile Gate and Fence Repairs

Specialize in quick metal repairs: trim and replace hinges, latch plates, and corroded sections on steel and stainless gates/railings. A van kit with die grinder and wheels enables fast, clean cutting on-site. Offer flat-rate callouts plus material add-ons.

Hands-On Metalwork Workshops

Host weekend classes teaching safe die-grinder use and small metal projects (hooks, shelves, wall art). Include a consumables fee that covers a pack of cutoff wheels, and upsell tool bundles. Partner with makerspaces and community colleges for venue and marketing.

Creative

Steel Skyline Silhouette

Cut a city skyline or mountain range from thin sheet steel using the 2-1/2 in wheels. Use A60T for cleaner edges and minimal cleanup, then mount the silhouette to a stained wood backer with standoffs for a floating effect. Add LED strip lighting behind for a dramatic wall piece.

Stainless Spice Rail Rack

Fabricate a minimalist spice rack from stainless flat bar and rod. Cut slots and notches for jars and S-hooks with A60T wheels, bend simple right-angle brackets, and fasten to a backsplash. The small wheel diameter is perfect for tight-radius cuts and clean corners in compact kitchens.

Upcycled Wrench Coat Hooks

Turn old wrenches and sockets into industrial-style hooks. Use the cutoff wheels to trim and angle wrenches, slice a backing plate from steel flat bar, and drill mounting holes. Arrange multiple sizes for a playful look; clear-coat or heat-bluish for character.

Compact Tabletop Fire Bowl

Create a small steel fire bowl or alcohol-fueled brazier. Cut a circular dish from thin plate, add ventilation slots and a simple ring stand from round stock. The 0.035 in Type 1 wheels excel at clean slotting and trimming without excessive kerf.

Industrial Desk Lamp

Build a pivoting desk lamp from steel conduit, angle offcuts, and a perforated shade. Use A36T wheels for fast cutting of brackets and conduit sections, then assemble with bolts or welds. Route the cord through the conduit for a tidy, industrial aesthetic.