Features

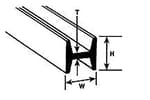

- H-Columns Polystyrene .100in x 14in Pack of 4 Evergreen

- Dimensions 14 in (35 cm) length x .100 in (2,5 mm)

- Four (4) Opaque White Styrene Angles H-Comumns, wide flange beams

Specifications

| Unit Count | 1 |

Four opaque white polystyrene H-columns, each 14 in (35 cm) long and 0.100 in (2.5 mm) in cross-sectional dimension. These wide-flange H-beams are intended for scale modeling and scratch-building to provide uniform structural members and detailing.

Evergreen Scale Models H-Column .100 4 EVG283 Plastic Building Supplies Review

Why I reach for these H-columns

There are a lot of ways to fake structural steel in a model. You can laminate strip, print something, or raid the recycle bin for improvised shapes. But when I want clean, repeatable, square profiles that behave predictably under the knife and solvent, I reach for Evergreen’s H-columns in the 0.100 in (2.5 mm) size. They’re simple pieces of polystyrene, four sticks per pack, each 14 inches long. That’s all they promise—and they deliver exactly that with a level of consistency that makes scratch-building less about wrestling material and more about building.

What you actually get

The pack includes four opaque white H-section beams. Each is 14 inches (about 35 cm) long with a cross-section that measures roughly 0.100 in (2.5 mm) across the flanges. They’re extruded polystyrene, not cast, so the profile is continuous and uniform from end to end. Out of the bag, mine were straight with crisp corners and no flash or surface texture. That uniformity is the whole point: you can cut multiple lengths and they’ll match perfectly without sanding a taper out of one piece or squaring up another.

Fit and finish

Evergreen’s reputation for clean, square extrusion holds up here. The H-shape has neat interior fillets—enough radius to avoid a fragile feather edge, but not so much that it reads as a rounded toy profile. Under magnification, the edges are sharp. With calipers, my pieces measured within a hair of the stated 0.100 in across the flanges, and thickness was consistent along the length. I saw no twist or bow in the sticks I used, which matters when you’re building trusses or frames where even a slight warp telegraphs through the assembly.

The surface is matte—not glossy—so it takes pencil marks and primer well. Solvent wicks nicely into the web and along the flange-to-web junctions, making those T-joints and lap joints easy to fuse cleanly.

Scale and sizing notes

The 0.100 in dimension translates differently depending on your scale. Roughly:

- 1:35 scale: reads as ~3.5 inches wide in the real world

- 1:48 (O): ~4.8 inches

- 1:72: ~7.2 inches

- 1:87 (HO): ~8.7 inches

That range puts this profile in a sweet spot for light structural steel in smaller scales or heavy bracing in larger scales. In HO, it convincingly suggests a compact wide-flange beam; in 1:35 it becomes more of a stiffener or architectural detail rather than a primary girder unless you’re stylizing. If you’re replacing a specific W-beam size, check your scale chart and Evergreen’s catalog carefully—the numbering can be close and it’s easy to grab 2.5 mm when you meant 4 mm.

Working the material

Polystyrene is forgiving if you respect its strengths. Here’s what worked best for me:

- Cutting: For square cuts, I prefer a razor saw and a small miter box. You can score-and-snap along the web if you’re dividing it lengthwise, but for cross-cuts on H-sections, scoring tends to crush the flange edges. A chopper with a fresh blade works for repetitive lengths up to about 6–8 mm; beyond that, a saw keeps faces truer.

- Shaping: A fine, rigid sanding block cleans up cuts without rounding over. The material sands quickly—go easy to keep corners sharp. If you need a chamfer or a distressed, bent-steel look, scrape with the back of a blade then refine with a sanding sponge.

- Drilling and pinning: Micro-bits plunge cleanly if you pilot first. I often pin joints with 0.3–0.5 mm brass wire in larger scales. The web will accept a pin; just avoid punching through the flange.

- Heat forming: You can introduce gentle bends with hot water or a hair dryer, but the H-profile wants to twist if you force it. For a “collapsed beam” effect, I score the inside of the intended bend and soften with a touch of solvent instead of heat.

Adhesives and compatibility

This is standard styrene, so all the usual solvent cements are fair game. Tamiya Extra Thin wicks beautifully into the seams, fusing flush joints almost invisibly. For mixed-media builds, CA glue bonds well, though I scuff the mating surface with 800–1000 grit for extra bite. Epoxy is overkill unless you’re embedding wire or magnets. The material takes putty and scribing cleanly; if you need to add plug-welds or gusset plates, thin sheet styrene and solvent cement integrate seamlessly.

Painting and finishing

A quick wash with isopropyl alcohol removes factory dust, and a light coat of primer (Stynylrez, Mr. Surfacer, or rattle-can automotive primer) adheres well. Acrylics, lacquers, and enamels all behave. For steel effects, I’ve had good results with a dark metallic base, oils for grime in the web, and graphite burnished along the flange edges. Because the edges are sharp, dry-brushing reads especially well. If you want the open ends to look like real I-beams, consider capping them with thin strip to suggest thickness or adding a hint of internal webbing; otherwise the extrusion reads as a thin-walled section under close inspection.

Use cases

- Diorama structure: I’ve used these as broken beams in urban rubble and sci-fi bases. The uniform profile sells the illusion even when distressed.

- Architectural scratch-building: Works as columns, lintels, and bracing in HO and N scales. The straightness helps keep frames square.

- Vehicle stowage and repairs: In military modeling, they make convincing field-expedient gantry frames or bed reinforcements.

- Jigs and fixtures: The H shape doubles as a handy straightedge or clamp caul during construction.

Strength and limitations

These are modeling materials, not load-bearing members. Solvent-welded assemblies are stiff, but the flanges can crush if you clamp too hard. Long, unsupported spans are prone to sagging over time, especially in warm environments. If you need a beam to support actual weight (display shelves, dynamic diorama elements), reinforce with brass or piano wire hidden in the web, or step up to thicker profiles. Also note that polystyrene is sensitive to strong solvents; aggressive lacquer thinners can craze the surface if you flood them on bare plastic.

Value and alternatives

You pay for precision and convenience here. Price-per-inch is higher than cutting strips from sheet or repurposing signboard plastics. But in my experience, the time saved and the consistency gained are worth it when alignment matters. Alternatives include:

- Plastruct: Offers similar shapes, often in ABS as well as styrene. ABS is tougher but doesn’t solvent-weld as seamlessly to styrene sheet.

- 3D printing: Fine for unique sizes, but printed layer lines and corner radii rarely match the crispness of extruded styrene without post-processing.

- Scratch from sheet: Cheapest and fully customizable, but keeping long, thin laminations square and identical is tedious.

If you’re filling a large scene with dozens of beams that will be heavily distressed, cheaper materials might pass muster. For clean, repeatable structural work, I find these H-columns justify their cost.

What I’d change

Two things would make these even better. First, clearer dimensional callouts on the packaging—specifically flange thickness, web thickness, and overall depth—would help modelers match prototype sections more precisely. Second, an option for gray styrene would reduce the number of primer coats needed to hide the bright white under metallic finishes. Neither is a deal-breaker, but both would smooth the workflow.

Recommendation

I recommend these Evergreen H-columns for modelers who value consistent geometry and reliable styrene behavior. They’re straight, clean, and dimensionally true, they bond seamlessly with common solvent cements, and they take paint beautifully. The cost is higher than improvised materials, so they’re not the best choice if you’re bulk-filling background rubble or experimenting on a budget. But for structural details you’ll actually notice—frames, bracing, exposed beams, and any place where square corners and repeatability matter—they’re worth it.

Project Ideas

Business

Miniature Structural Kits

Design and sell small 'structural framing' kits for modelers and architects that include pre-cut H-column sections, connector pieces, and instructions for building common structures (bridges, towers, warehouses). Market as beginner-friendly kits for hobby stores, online marketplaces, and model-railroad clubs.

Architectural Model Supply Packs

Package the H-columns into curated supply bundles (varied lengths, pre-primed pieces, and matching styrene plates) targeted at architecture students and professionals. Offer custom-cutting services, color priming, or bulk discounts to studios and schools to differentiate from commodity suppliers.

Workshops and Mini-Classes

Host paid workshops—online or in person—teaching techniques for scratch-building using H-columns (cutting, mitering, weathering, and painting). Provide a materials kit including the H-columns and sell follow-up kits or advanced lesson packages to attendees.

Etsy/Shopify Niche Products

Create finished decorative items (industrial desk sculptures, small shelving units for collectibles, or lamp bases) made from the H-columns and market them on Etsy or Shopify. Emphasize handmade, upcycled, and bespoke options (custom colors, sizes, or engraved nameplates).

Subscription Micro-Materials Box

Launch a monthly micro-supply subscription for modelers that includes a mix of small specialty parts (including H-columns), hardware, adhesives, and project plans. Each box focuses on a mini-project that demonstrates novel uses of the H-columns to keep subscribers engaged and encourage recurring revenue.

Creative

Miniature Skyscraper Framework

Use the H-columns as the primary structural skeleton for a scale skyscraper or industrial building model. Cut the 14 in columns to desired heights, glue in orthogonal grids to simulate beams and columns, then add styrene sheet walls, windows, and surface details. The uniform cross-section makes it easy to create realistic wide‑flange girders and consistent floor spacing.

Dollhouse or Diorama Support Beams

Integrate the H-columns as exposed support beams, interior trusses, or loft joists in dollhouses and dioramas. Their durable polystyrene material is easy to paint, weather, and scratch-build around—ideal for adding industrial or modern architectural character to interiors and attics.

Custom Shelving for Miniatures

Build tiny cantilevered shelves, loading docks, or mezzanine platforms for model railways and tabletop gaming terrain. Use the H-columns as uprights or shelf brackets; their flat flanges offer good gluing surfaces for thin plywood or styrene shelf pieces and provide a crisp, structural look when painted.

Artistic Geometric Sculpture

Create small modern sculptures or mobile pieces by cutting the columns into repeating lengths and assembling them into interlocking geometric forms. Paint in contrasting colors or metallic finishes; the consistent profile yields a clean, modular aesthetic suitable for desk art or gallery displays.

Lamp or Candle Holder Base

Combine lengths of the H-columns into a decorative base or stem for a small lamp, LED candle holder, or incense stand. Their hollow appearance can be reinforced internally with epoxy or dowels for strength, then sanded and finished with metallic paints to mimic steel I‑beams for an industrial look.