Features

- Engineered for extended life

- Sintered segments for enhanced strength

- Standard 7/8" bore hole

- Optimized diamond formula for cutting applications

Specifications

| Arbor | 7/8", 20 mm, 5/8" |

| Cutting Depth | 1-1/4" |

| Compatible Tools | Small angle grinder, tile cutter |

| Application | Marble |

| Pack Quantity | 1 |

| Bore | Standard 7/8" bore hole |

Related Tools

Related Articles

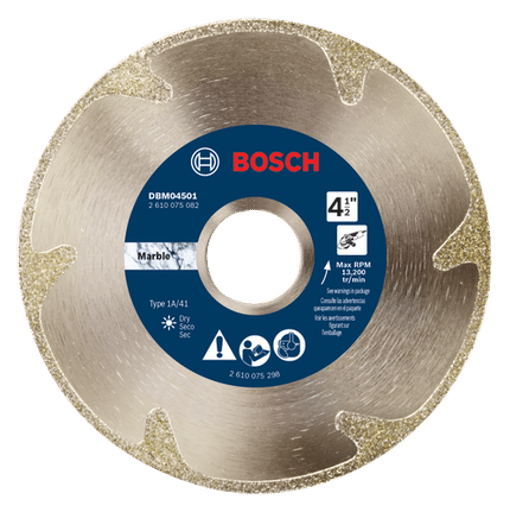

Segmented rim V-groove diamond blade intended for cutting marble. Suitable for use with small angle grinders and tile cutters; provides approximately 1-1/4" cutting depth and fits common arbor sizes.

Bosch Segmented Rim V-Groove Diamond Blade Review

Why this blade caught my attention

Cutting marble sits in an awkward middle ground: it’s soft and prone to bruising compared to porcelain, but it still demands a fast, steady blade that won’t wander or burn. I’m always looking for a wheel I can throw on a small grinder or a tile saw that balances speed, control, and finish. The Bosch V-groove blade fits that brief on paper—segmented rim for speed and cooling, an optimized diamond formula for stone, and a practical 1-1/4-inch cutting depth. I put it to work with that balance in mind: clean enough for visible edges, quick enough to make progress on long rips, and durable enough for a weekend of tile work without cratering.

Setup and fit

The blade drops onto common arbor sizes—7/8 inch, 20 mm, and 5/8 inch—so it pairs easily with most small angle grinders and tile cutters. Fit on my grinder was snug with no wobble, and balance was good out of the box. The maximum cutting depth of 1-1/4 inch is realistic for a compact wheel in this class and lines up with typical 4-1/2-inch blade geometry. That depth covers standard marble tile, cap pieces, and many trim profiles; it’s tight but workable for 3 cm material if your guard clearance allows and your cut setup is dialed. As always, confirm your tool’s guard and flange compatibility, check the rotation arrow on the blade, and run it up to speed for a moment before a first cut to make sure there’s no vibration.

Cutting performance on marble

Marble rewards a steady hand and a blade that sheds dust rather than smearing it across the cut. The segmented V-groove design here helps eject swarf and lets the rim breathe—heat stayed manageable with light, consistent feed pressure. On straight rips in 3/8- to 1/2-inch marble tile, the blade maintained a confident bite without grabbing. Feed rates were comfortably quick on a grinder; on a tile cutter, the cut tracked straight without bogging down.

Edge quality was better than I typically expect from a segmented rim. It won’t fully match a fine continuous rim on polished marble if you’re chasing a showroom edge straight off the saw, but chips stayed small and predictable when I scored the line, kept the feed speed even, and supported the offcut. For visible edges, a light pass with a honing stone or 200–400 grit pad brought the edge to a presentable finish.

Control, tracking, and chip management

The kerf felt consistent, with minimal lateral wander. The blade didn’t push the work off line, which is often where segmented wheels get in trouble. The V-groove segment geometry seems to help with debris clearing and reduces that “hammering” feel you get when segments are too sparse. On inside corners and notches, plunge cuts started cleanly without bouncing when I eased into the material. If you’re prone to chipping at exit, tape the underside, support the waste, and consider a short back-cut to meet a primary rip—this blade responds well to those standard marble tricks.

Heat and dust

Running on a water-fed tile cutter unsurprisingly improved surface finish and extended cut time between dressings. On a dry grinder, the blade stayed composed with shallow passes and good dust extraction. If you push hard and linger, marble will still bruise and the rim will glaze—standard behavior. A quick dress on a silicon carbide dressing stone restored bite when I noticed the feed rate tailing off. Sound levels and vibration were in line with other quality segmented wheels of this size; no odd harmonics or rattling as long as the tool was properly tightened.

Durability and life

The sintered segments are the right choice for longevity. Over the course of typical tile work—rips, notches, a few bevel passes—the wear rate was slow and even. Segment corners held their shape rather than crumbling, which keeps the cut straight across the life of the blade. As with any diamond blade, life depends heavily on technique: let the diamonds do the work, keep the cut straight, and avoid prying in the kerf. The optimized diamond matrix here feels tuned for calcitic stone rather than glassy porcelain; that’s exactly what you want for marble.

Versatility and limitations

This blade’s sweet spot is marble and similarly soft to mid-density natural stone tiles. It will make short work of baseboards, thresholds, smaller trim pieces, and field tile. It’s serviceable for occasional cuts in other stones if you slow down and keep the passes light, but if your day job is porcelain or granite, a blade engineered for those materials will outperform it in speed and edge quality. For extremely clean edges on polished marble—think exposed waterfall edges—switching to a continuous rim for the final pass or planning to knock down the edge with a polishing pad is still the safer bet.

The 1-1/4-inch depth is a practical upper bound, not a challenge to exceed. If you regularly cut thicker material, step up in blade diameter or move to a rail saw. The segmented design favors speed and cooling over the absolute cleanest edge, so match it to tasks where you can either hide the cut or are willing to do light finishing.

Handling and user experience

What stood out most was predictability. The blade spools up cleanly, bites without snatching, and signals clearly when you’re pushing too hard—the feed stiffens before you get into trouble. That kind of feedback matters when you’re freehanding on a grinder. On a tile cutter, the carriage feel remained smooth, and the cut didn’t load the motor excessively. The blade runs true, which helps avoid micro-chips caused by lateral oscillation.

Practical tip: score a shallow line first, then commit to full depth in one or two passes. On outside corners, stop short and finish with the work supported to keep the last bit from popping out. If you’re cutting dry, a shroud and vac aren’t optional—marble dust is heavy and pervasive.

Value and who it suits

In the category of compact diamond blades for stone, this Bosch V-groove blade hits a sensible balance of speed, control, and lifespan. You can spend more for a premium continuous rim dedicated to pristine edges, and you can spend less on a bargain segmented wheel that burns out by lunch. This one lands in a useful middle: robust enough for repeated weekend projects or light professional use, clean enough that you’re not stuck sanding every single cut, and versatile across both grinders and tile cutters thanks to the common arbor options.

It’s a good match for tile setters working primarily in marble, remodelers who need a reliable blade for occasional stone tasks, and serious DIYers setting bathroom or fireplace surrounds. Stone fabricators will still keep specialty blades on hand, but this makes a dependable utility option for on-site adjustments.

Bottom line

Recommendation: I recommend this blade for anyone cutting marble tile or similarly soft stone who wants a fast, predictable segmented wheel with respectable edge quality. The reasons are straightforward: the segment design manages heat and debris well, the diamond matrix is tuned for the material, the arbor options make setup painless, and the 1-1/4-inch cutting depth covers the majority of tile work. If your priority is the absolute cleanest edge on polished faces, pair it with a continuous rim for finish passes. If you need a one-blade workhorse for marble on a small grinder or tile cutter, this Bosch V-groove blade earns a spot in the kit.

Project Ideas

Business

Mobile Marble Lettering & Monogramming

Offer on-site V-cut engraving for fireplace surrounds, hearths, thresholds, benches, and fountains. Provide paint/metallic infill and sealing as add-ons. Market to interior designers and homeowners for fast, dust-controlled personalization without removing installed stone.

Decorative Tile Liners and Medallions

Produce V-grooved accent strips (listellos), corner pieces, and medallions for tile installers. Use repeatable patterns (Greek key, chevrons) and fill grooves with contrasting resin to create a premium upsell SKUs. Sell wholesale to tile shops and builders.

Anti-Slip V-Grooving for Steps & Thresholds

Add parallel V-groove safety lines to marble stair treads, exterior stoops, and shower thresholds to improve traction and meet safety specs. Package as a quick retrofit service for contractors, property managers, and hotels with per-step pricing.

Upcycled Marble Offcut Products

Partner with countertop fabricators to acquire offcuts and turn them into coasters, pastry boards, charcuterie trays, and address plaques with V-grooved designs. Brand the line, batch finish, and sell via Etsy, local boutiques, and corporate gift programs.

Hands-On Workshops and Content

Host weekend classes teaching safe angle-grinder use and V-groove techniques to make an address plaque or coaster set. Sell tool-and-material kits, record content for YouTube/shorts, and monetize through class fees, sponsorships, and affiliate links.

Creative

Art Deco V-Inlay Wall Panel

Cut geometric V-grooves into marble tile panels using the blade’s crisp V profile, then fill the channels with contrasting resin (black, brass-colored, or gold leaf) to create striking Art Deco lines and sunburst motifs. The ~1-1/4" depth lets you vary line weight for layered effects; mount multiple panels as a statement piece.

Engraved Garden Stepping Stones

Engrave leaves, compass roses, or Celtic knots into marble pavers by V-grooving outlines and details. Paint- or epoxy-fill the grooves for weatherproof contrast and chamfer the edges to reduce chipping. The standard 7/8" arbor fits a common angle grinder for easy on-site work.

Mosaic Coffee Table with Brass Inlays

Cut marble into triangles and rhombuses for a mosaic top, then V-groove channels to accept thin brass rod or metallic epoxy inlays that accent seams. The V profile creates light-catching facets around each tessera, elevating the piece from DIY to gallery-grade.

V-Cut Address Plaques

Carve deep V-cut numerals, names, and border lines into marble slabs for elegant address plaques. Color-fill the cuts or apply gold leaf for high contrast, drill mounting holes or keyholes, and seal the surface for outdoor durability.

Coaster & Trivet Set with Beveled Borders

Cut marble offcuts into coasters/trivets, then run a shallow V-groove around the perimeter to create a refined beveled frame. Add minimal line art (mountains, initials) in the center, fill with pigment, and back with cork for a premium handmade set.