Features

- Induction-hardened alternating top bevel (ATB) carbide teeth

- Clear anti-stick coating to reduce friction and resist rust/oxidation

- Thin kerf for reduced material removal

- Anti-kickback shoulders for safer, straighter cuts

- Expansion slots to reduce vibration and help the blade run true

- Diamond knockout arbor allowing 5/8-inch or diamond-shaped mounting

Specifications

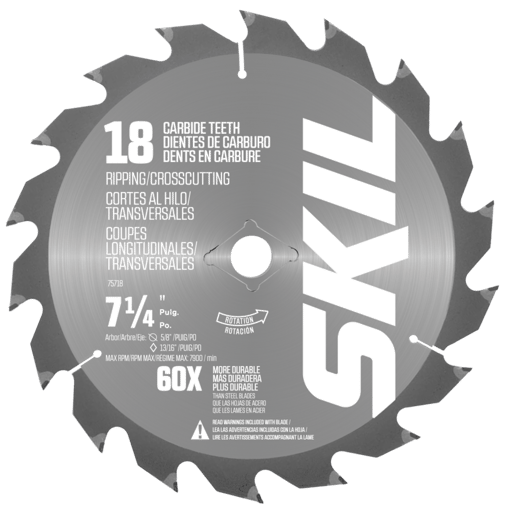

| Blade Diameter | 7-1/4 in |

| Number Of Teeth | 18 |

| Kerf | 0.06 in |

| Tooth Composition | Carbide |

| Arbor | 5/8 in + diamond knockout |

| Anti Kickback Shoulder | Yes |

| Expansion Slots | Yes |

| Anti Stick Coating | Yes |

| Package Quantity | 25 pcs |

| Cut Finish | Rough |

Related Tools

Related Articles

Pack of 25 circular saw blades designed for general-purpose cutting and framing. Blades have induction-hardened alternating top bevel carbide teeth, a clear anti-stick coating to reduce friction and resist corrosion, a thin kerf for reduced material removal, and expansion slots to limit vibration. A diamond knockout arbor provides compatibility with a standard 5/8-inch arbor or a diamond-shaped arbor.

Skil 7-1/4 in 18-tooth carbide-tipped circular saw blade (25-pack) Review

Why I reached for this blade

On a recent framing-heavy remodel and a deck build that followed, I needed a fast-cutting blade I wouldn’t feel precious about when it inevitably met wet lumber, construction adhesive, and the occasional hidden staple. That’s what pushed me to the Skil 7-1/4-in 18T blade—specifically the 25-pack. The simplified feature set and bulk quantity make a lot of sense for rough carpentry: induction-hardened ATB carbide teeth for durability, a thin 0.06-inch kerf to keep cordless saws from bogging, and expansion slots so the blade stays true when it heats up. The diamond knockout is a nod to worm-drive users, and the anti-stick coating helps shed pitch and moisture.

This is not a finish blade. It’s a jobsite workhorse for fast, rough cuts. That’s exactly how I used it, and here’s how it stacked up.

Setup and compatibility

I ran these on both a standard 5/8-inch arbor sidewinder and a worm-drive saw using the diamond knockout. The knockout popped cleanly with a couple taps on a firm surface and seated well with no slop. The thin kerf is a real advantage with 18V/20V max saws—less drag translates into better runtime and a steadier cut when you’re pushing through dense or wet stock. Blade installation was straightforward, and the printed rotation arrow and tooth orientation are easy to read.

Cutting speed and control

Framing lumber (SPF, SYP, and pressure-treated): The 18 teeth and generous gullets move chips quickly. I was able to feed 2x stock at a brisk pace without the motor lugging. On pressure-treated lumber, the blade still tracked straight with minimal hesitation—helped by the anti-stick coating when the wood was wet from the yard.

Sheet goods (OSB and construction-grade plywood): The blade tore through OSB without fuss. With plywood, the cut line is serviceable for framing but you’ll see splintering on the face veneer, especially crosscutting. If you need cleaner edges, score the cut line or switch to a 40T+ blade.

Engineered lumber (LVL): Rips through 1-3/4-inch LVL were possible, though I slowed the feed slightly to keep heat in check. The expansion slots seemed to do their job: no noticeable warping or singing, and the blade stayed true during longer cuts.

The anti-kickback shoulders are there for a reason—on plunge starts and rips in wet PT, the blade felt composed. It’s not a cure-all for poor technique, but the shoulders help the blade engage more predictably.

Cut quality

As expected for an 18T design, the finish is rough. End grain on 2x stock shows minimal burning, even when I lingered at the end of a cut. Crosscut tear-out in construction plywood is moderate; with OSB it’s a non-issue. If I’m framing walls, decking, or building temporary jigs, I don’t hesitate to use this blade. For visible edges and trim-adjacent work, I swap to a finer-tooth blade after rough sizing.

The ATB grind does help create a cleaner shoulder than a flat-top grind would at this tooth count, but don’t mistake that for a finish cut. This is a fast, get-it-done profile.

Vibration, heat, and noise

The combination of thin kerf and expansion slots is well balanced. Thinner plates can wander if you force the cut or if the shoe isn’t firmly supported, but I didn’t see measurable deflection unless I tried to force the feed. Keep the base flat, let the teeth do the work, and it tracks straight.

Heat build-up was typical for aggressive cuts in dense material. After repeated rips in PT, the blade was warm but not blueing. The anti-stick coating seemed to limit pitch accumulation—after a day on lumber and OSB, the teeth and plate were noticeably cleaner than economy blades I’ve used without coatings. Noise is about what I expect from an 18T blade: a sharper note than a 24T in some cuts, but not unpleasant.

Durability and life

Carbide tips on an 18T blade take a beating. Over two projects, I rotated through a handful of blades. Here’s what I noticed:

Edge retention: In clean softwoods and OSB, each blade stayed sharp for a few days of intermittent use. On a pure framing schedule, I’d plan to swap every day or two to keep feed rates high.

Abuse tolerance: Hitting a hidden staple chipped one tooth on a blade but didn’t derail the cut. With the 25-pack, I didn’t bother to resharpen—swap and keep moving is the jobsite advantage of buying in bulk.

Plate integrity: No warping, no loose teeth, and the expansion slots remained crack-free. The plates run true if you keep them out of binds; forcing crooked rips in thick PT will flex a thin kerf, but that’s operator error, not a blade defect.

For a rough-cut blade, longevity is solid, especially given the thin kerf. If you’re constantly in nail-embedded wood or demo, consider a dedicated demolition blade. This one’ll survive occasional hits but it’s not designed to chew through metal.

Real-world usability

What makes this blade useful is predictability. On framing tasks—studs, joists, rafters, and decking—it’s quick, stays relatively clean, and doesn’t bog cordless saws. The diamond knockout extends its utility to worm drives without buying a separate SKU. And because it’s a 25-pack, I don’t baby it. If a blade dulls mid-day, I swap it and keep going.

If I have to nitpick, 18 teeth is an aggressive choice compared to the more common 24T framing blades. You gain speed and chip clearance, but you pay with slightly rougher edges and a bit more splash-out on the exit side of plywood. That trade-off worked for my projects; your mix of materials might point you to 24T if you want a touch more refinement without going to a finish blade.

Tips for getting the most out of it

- Set the blade depth so the gullets just clear the work. It reduces tear-out and improves control.

- Support sheet goods well to avoid pinching; thin-kerf blades don’t like binds.

- For cleaner plywood edges, score the cut line or cut with the good face down on a sidewinder.

- Keep a plastic bristle brush and resin cleaner handy; even with the coating, PT and pine can gum up teeth over time.

- Use the diamond knockout only when needed; you can’t put it back.

Who it’s for

- Framers and remodelers who burn through blades on rough work and value quick swaps.

- Deck builders working in wet PT where a coated, thin-kerf blade helps maintain cut speed.

- DIYers tackling large structural projects who don’t want to overspend on premium finish blades they don’t need.

Who it’s not for: finish carpenters, cabinetmakers, or anyone expecting clean crosscuts in hardwoods and fine plywood straight off the saw. Also not ideal as a dedicated demo blade.

Pros

- Fast feed rate in 2x stock and OSB

- Thin 0.06-inch kerf helps cordless saws maintain speed and runtime

- Anti-stick coating reduces friction and pitch buildup

- Expansion slots keep the plate stable under heat

- Diamond knockout adds worm-drive compatibility

- Bulk pack makes it easy to swap rather than nurse a dull blade

Cons

- Rough cut quality; not suited for finish work

- Slightly more tear-out in plywood than a 24T framing blade

- Thin kerf can deflect if you force the cut or bind the blade

- Not designed for frequent nail-embedded or demo work

Final recommendation

I recommend the Skil 7-1/4-in 18T blade if your work leans toward framing, decking, and other rough carpentry where speed matters more than surface quality. It’s a straightforward, jobsite-ready blade that runs cool enough, stays reasonably clean, and offers consistent performance across a large pack. The thin kerf and coating pair nicely with cordless saws, and the diamond knockout broadens compatibility. If you need cleaner edges or routinely cut finish materials, keep a finer-tooth blade on hand. But as a fast, reliable cutter you don’t mind swapping out when it dulls, this 25-pack hits the mark.

Project Ideas

Business

Framing & Demo Pop-Up Crew

Offer rapid framing and selective demo services for homeowners and small GCs. Market speed and reliability: 25 blades means you swap the moment performance drops and keep productivity high. Specialize in walls, openings, and roof/dormer framing where fast, rough cuts are ideal.

Mobile Deck and Fence Blitz Days

Run weekend blitz builds for decks and fences using pressure-treated lumber. The anti-stick coating and thin kerf excel in wet PT stock, and extra blades ensure consistent cut speed all day. Package fixed-price tiers (materials + labor) and upsell add-ons like gates and lighting.

Event/Film Set Carpentry

Provide quick-turn set builds where rough framing gets skinned and painted later. The 18T blades shine for fast layout, ripping flats, and framing platforms. Offer day-rate crews with a consumables fee that includes blades, fasteners, and adhesives.

Reclaimed Lumber Prep Service

Source and de-nail reclaimed boards, then rough-cut to standardized lengths for makers and furniture shops. Use carbide-tipped blades for efficient rough sizing (always metal-detect first), and sell sorted bundles by species and dimension for predictable inventory.

Contractor Blade Subscription/Micro-Store

Bundle these 7-1/4 in 18T blades into monthly subscriptions for small crews. Offer tiered plans (e.g., 10, 25, 50 blades/month), local delivery, and swap-in diamond knockout versions for worm-drive users. Add upsells like framing squares, chalk, and pencils for a one-stop refill.

Creative

Weekend Shed/Bike Garage Build

Use the fast-cutting 18T blades to frame a compact shed or bike garage from 2x lumber and OSB. The thin kerf keeps the saw moving easily through studs and sheathing, while anti-kickback shoulders help with straight, safe rips. The rough-cut finish is fine for a utility structure you’ll paint or clad later.

Rustic Pallet Feature Wall + Floating Shelves

Break down de-nailed pallets and quickly rip/trim boards to length for a textured accent wall and matching shelves. The ATB carbide teeth handle knotty, resinous boards, and the anti-stick coating reduces drag when cutting stacks. Embrace the rough-sawn look; just sand edges lightly before install.

Raised Garden Bed Production Line

Batch-cut pressure-treated 2x lumber for a series of raised beds. The blade’s expansion slots help keep it running true during repetitive cuts, and the thin kerf makes quick work of wet, heavy boards. Add corner caps and a simple top rail for a clean finish after assembly.

Backyard Playhouse or Obstacle Course

Frame a kid’s playhouse or ninja-style obstacle course using 2x4s, 2x6s, and plywood. The 18-tooth count excels at fast, straight rips and crosscuts for structural pieces. Build platforms, monkey bars, and balance beams; paint or wrap edges after to soften the rough construction.

Festival/Pop-Up Art Structures

Design modular frames for large-scale art or temporary installations. The rough-cut blades let you rip long lengths and bevel edges quickly for triangles, arches, and lattices. The diamond knockout arbor works with worm-drive saws commonly used on site framing crews.