Features

- High-performance silicon carbide abrasive

- Resin-over-resin bond to resist loading

- Cloth backing for durability and extended life

- Made for use with heavy-duty belt sanders

- Suitable for wood, tile, and concrete floors

- Offered in multiple diameters and grits

Specifications

| Bond | Resin-over-resin |

| Backing | Cloth backing |

| Abrasive | Silicon carbide (high-performance) |

| Intended Use | Floor sanding (wood, tile, concrete) |

| Product Status | Discontinued (as listed on source) |

| Available Grits | Common grits listed include 12, 16, 20, 24, 36, 40, 60, 80, 100 |

| Available Sizes | 16 in. x 2 in.; 17 in. x 2 in.; 20 in. x 2 in. |

| Recommended Tool | Heavy-duty belt sander |

Related Tools

Related Articles

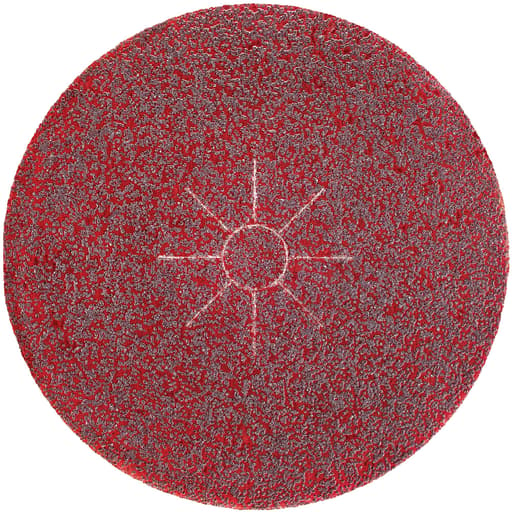

Abrasive sanding discs with silicon carbide abrasive on a cloth backing and a resin-over-resin bond designed to reduce loading. Intended for floor sanding with heavy-duty belt sanders and suitable for use on wood, tile, and concrete surfaces.

Project Ideas

Business

Transition blending service

Offer a niche service that levels and visually blends transitions between wood, tile, and concrete floors in renovations. Use coarse grits for flattening and lippage removal, then finish with 80–100 grit for a uniform sheen. Great upsell for remodelers and designers.

Garage and basement epoxy prep

Provide mechanical profiling for small to mid-size concrete floors prior to epoxy or polyaspartic coatings. Silicon carbide discs produce a consistent scratch pattern and resist loading in dusty conditions, reducing the need for shot blasting on residential jobs.

Commercial screen-and-recoat plans

Sell maintenance contracts to gyms, studios, and event halls. Use higher grits (80–100) to screen existing wood finishes and apply fast-dry topcoats. Package quarterly or biannual visits to keep floors safe and glossy with minimal downtime.

Tile and stone lippage removal

Specialize in correcting minor lippage and honing on stone and cement-based tile installations, especially small areas where full grinding rigs are overkill. Progress grits to achieve a uniform satin finish and re-seal. Market to tile contractors and homeowners post-install.

DIY floor refinish rental kits

Bundle a compatible heavy-duty sander, a grit progression of discs, dust control accessories, and a step-by-step guide. Rent weekend packages to homeowners and property managers for wood or concrete refreshes. Add-on sales: extra discs, sealers, pads.

Creative

Terrazzo-look concrete coffee table

Cast a concrete slab with mixed aggregates, then use coarse-to-fine silicon carbide discs (36 → 60 → 100) to hone and reveal the stones. The resin-over-resin bond resists loading in cement dust, and the durable cloth backing holds up during edge easing. Finish with penetrating sealer for a satin, modern look.

Mixed-material foyer refinish

Blend transitions between hardwood, tile, and a concrete threshold in an entryway. Use 24–36 grit to flatten high spots and tile lippage, then step through 60–100 grit for a cohesive sheen across materials. Ideal for creating a seamless, custom inlay feel without replacing flooring.

Outdoor mosaic stepping stones

Set broken tile or stone in concrete pavers, then level and texture with the discs. Start with 24–40 grit to knock down edges, then 80–100 grit for a slip-resistant satin finish. The discs’ wide format and loading resistance make quick work of cementitious surfaces.

Skate ramp and deck refresh

Resurface plywood skate ramps or refurbish skateboard decks. Use 36–60 grit to remove splinters and old coatings, then 80–100 grit to burnish the riding surface for smooth, predictable friction. The cloth-backed discs endure heat and heavy passes.

Concrete relief wall panels

Create textured art panels by casting flat concrete slabs and abrading designs through stencils. Coarse grits carve shallow relief; finer grits refine edges and sheen. The silicon carbide grain cuts fast on mineral surfaces for crisp, durable patterns.