Features

- High‑carbon steel cutting edge for general-purpose wood cutting

- Segmented cutting edge for straight and flush cuts

- Starlock three‑dimensional mount for improved torque transfer and reduced vibration

- Quick blade change with Starlock interface

- Color-coded interface and laser-etched identification for fast selection

- Compatible with OIS and many brand oscillating multi-tools

- Manufactured in Switzerland

Specifications

| Model Number | OSL312 |

| Material | High‑carbon steel (HCS) |

| Blade Size | 3-1/2 in |

| Blade Length | 3 in |

| Blade Thickness | 0.125 in |

| Application | Cutting wood |

| Width (In) | 3.5 |

| Immersion Depth (In) | 1.5 |

| Pack Quantity | 1 |

Related Tools

Related Articles

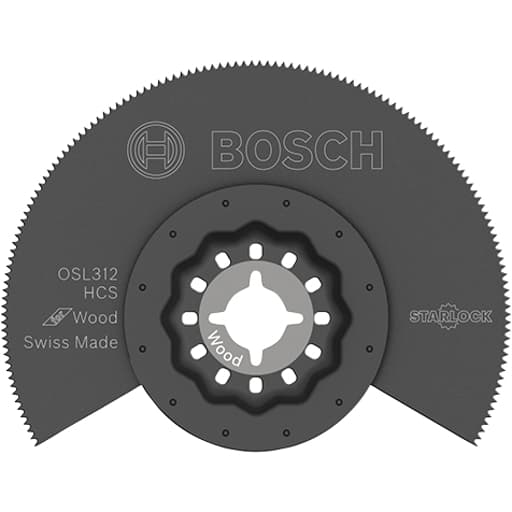

Segmented saw blade for oscillating multi-tools, intended for general-purpose wood cutting. The blade uses a Starlock three-dimensional mounting interface to improve torque transfer and reduce vibration; it is compatible with OIS-compatible tool interfaces.

Bosch 3-1/2 In. Starlock High-Carbon Steel Segmented Saw Blade Review

Why I reached for this blade

I’ve been swapping blades on oscillating multi-tools for more years than I care to count, and a segmented wood blade is one I always keep nearby. I used the Bosch Starlock segmented blade across a handful of typical tasks: undercutting door jambs for new flooring, flush-cutting baseboard returns, trimming plywood for outlet cut-ins, and making a few careful notches in softwood shelving. I also pushed it into some denser, resin-laden sheet goods to see how it handled tougher, less forgiving material.

Build and interface

The headline feature here is the Starlock interface. The three-dimensional mount locks the blade positively to a Starlock-capable tool without a screw or pin, and it genuinely improves energy transfer. You feel it in use: less chatter, fewer false starts, and a cleaner “bite” when you begin a plunge cut. On a compatible tool, the quick-change action is excellent—touch and click on, pull to release, no burned fingers.

The blade itself is high-carbon steel (HCS), which is the right call for general-purpose wood cutting and trim work. HCS is sharp and smooth out of the package, but it’s not a “hit a nail and keep going” material; more on that in durability. The segmented edge allows you to run straight along a surface or get into inside corners without the overcut you’d get from a circular profile. At 3-1/2 inches wide with about 1-1/2 inches of immersion depth, it hits the sweet spot for door-jamb undercuts, flooring transitions, and flush-trim tasks where control matters more than raw speed.

Fit and finish are what I’ve come to expect from Swiss-made Bosch blades: clean grind, consistent tooth geometry, laser-etched markings that don’t disappear after the first cut, and a color cue that makes it easy to grab the right blade out of a crowded box.

Compatibility and setup

On Starlock and Starlock-compatible tools, this is plug-and-play. If your multi-tool uses an older OIS interface or a bolt clamp, the blade is still broadly compatible, but your experience won’t include the hands-free click-on change. You’ll be clamping it like any other accessory. I ran it both ways—on a Starlock tool and on an older OIS clamp machine—and the cutting feel was better on the Starlock body, mostly due to the stiffer, slip-free connection. Either way, check your tool’s compatibility chart if you’re unsure.

Cutting performance in wood

Softwoods and trim: In pine, fir, and typical painted trim, the blade tracks straight and cuts predictably. For flush cuts, the segmented arc lets you “walk” along a surface with good control. The kerf it leaves is clean enough that a light sanding hides the cut in most paint-grade applications. I had no trouble undercutting four door jambs and casings for laminate flooring in one session, with consistent results.

Plywood and MDF: In cabinet-grade plywood, I got smooth edges when I let the blade do the work and kept the oscillation speed in the mid-high range. MDF was also clean, but the dust gets fine fast; extraction helps. Plunge cuts for outlet boxes in 1/2-inch ply went cleanly—score the face veneer with a light pass and then drive to depth.

Hardwood: In oak and maple, the blade remains accurate but slows down. That’s normal for HCS; if I needed to do a stack of hardwood notches, I’d reach for a finer-tooth or bi-metal option. For occasional hardwood trims or flush cuts, it’s fine.

Engineered/pressed wood siding and dense composites: This is where the limits show. Resin-heavy, compressed materials tend to heat the teeth and gum up the gullets, which slows progress and dulls the edge sooner. I could muscle through, but the cut rate dropped, and the blade clearly wasn’t in its element. A carbide-toothed or at least a more aggressive tooth pattern would be a better match for those materials.

Heat buildup is manageable if you resist the urge to lean on the tool. Let the oscillation do the cutting, feather the pressure, and clear chips with a short retreat if you sense drag. If you smell scorching, back off and drop the speed a notch.

Control, vibration, and visibility

The Starlock mount delivers on its promise of reduced vibration. The blade feels solidly coupled, and that translates into control, especially for delicate flush cuts around finished surfaces. The segmented profile also gives better line-of-sight than a full semicircle, and the shallow immersion depth keeps you honest—it’s enough for casing, jambs, and trim, but it won’t let you dive recklessly into deeper structure.

On long straight cuts, the wide arc helps act like a mini fence. I often lay my free hand against the tool body to steady it and run the blade’s rim along the work; with this blade that technique works well.

Durability and wear

This is a wood blade, not a demolition blade. As long as you stay clear of nails, screws, and staples, edge life is perfectly serviceable for trim carpentry and carpentry punch-list work. Hit metal and you’ll ding the teeth quickly. In resinous composites (think certain pressed siding products), I noticed faster dulling and more heat. You can extend life by:

- Marking and avoiding fasteners with a detector.

- Cleaning pitch and resin from the teeth with a quick solvent wipe.

- Letting the blade cool between long cuts.

Once dull, HCS teeth on this style of blade aren’t practical to resharpen. Plan on it being consumable and keep a spare in the case if you’re doing a full day of trim work.

Where it shines

- Undercutting door jambs and casing for flooring.

- Flush-trimming baseboard returns and shims.

- Plunge cutting outlet openings in plywood and MDF.

- Scribing and notching softwood shelving and cabinet fillers.

- Trimming back drywall or softwood where a circular saw won’t fit.

The segmented edge and rigid interface reward a patient, accurate approach. If your work leans toward finish carpentry or controlled, flush work, this blade fits right in.

What it’s not for

- Nail-embedded lumber or unknown tear-out demolition.

- Fiber-cement, tile backer, or masonry—use carbide or diamond-grit.

- Extended cutting in dense, resin-bound engineered siding or similar composites.

- Fast ripping of thick hardwoods—better served by a jigsaw or circular saw.

For mixed-material tear-out or anything with metal surprises, jump to a bi-metal or carbide-tooth oscillating blade. For abrasive siding and cementitious products, go carbide grit.

Practical tips for best results

- Score first, then commit: Make a light, shallow pass to define the cut and reduce splintering, then finish to depth.

- Let it oscillate: Moderate speed, light pressure. Pushing hard just heats the teeth and slows you down.

- Keep it flat: For flush cuts, keep the blade flat to the surface and “walk” the segmented rim for a straighter line.

- Mind depth: With about 1-1/2 inches of immersion, plan your approach if you need deeper access—cut from both sides where possible.

- Stay organized: The laser-etched markings and color band help you grab it quickly among a pile of accessories; take advantage by storing it where you can see the face.

Value and availability

Sold as a single blade, it’s positioned as a general-purpose wood cutter rather than a long-life demolition accessory. The build quality is high, and the Starlock convenience is real value if your tool supports it. If you’re primarily doing trim and cabinet work, one blade should carry you through a fair amount of tasks before it needs replacement. For heavier or more abrasive use, plan on stepping up to a more robust tooth material and budgeting accordingly.

Recommendation

I recommend the Bosch Starlock segmented blade for finish carpenters, remodelers, and DIYers who need a reliable, controllable wood blade for trim, jambs, plywood, and MDF. It cuts cleanly, mounts securely, and excels at flush and corner work. I would not recommend it for metal-laden demolition or for extended cutting in dense engineered siding and other abrasive composites—choose a bi-metal or carbide blade for those jobs. Used in its lane, it’s a dependable, easy-to-control cutter that earns a spot in the kit.

Project Ideas

Business

Door Jamb Undercutting Service

Offer fast, dust‑controlled undercuts of door casings and jambs for tile, LVP, and hardwood installers. The 3‑1/2 in segmented blade makes precise, flush cuts against floors and guides, speeding installs and improving finish quality.

On‑Site Trim and Cabinet Modifications

Provide mobile trim tweaks: scribe fillers, shorten toe‑kicks, create outlet cutouts, and flush‑trim plug repairs without removing cabinets. Starlock quick changes keep you efficient across varied tasks in occupied spaces.

Custom Register and Vent Retrofits

Retrofit wooden wall/ceiling paneling and cabinet faces with new vent and return openings. Clean plunge cuts produce square, paint‑ready edges and minimize rework for HVAC and millwork contractors.

Flush Plug and Patch Specialist

Repair damaged trim and stair treads by cutting clean scarf joints, inserting patches, and flush‑trimming wooden plugs over fasteners. Sell a fixed‑price ‘invisible repair’ service to realtors and punch‑list clients.

Tiny Home and Van Interior Cutouts

Partner with upfitters to create precise openings in plywood interiors for outlets, access panels, and vents, plus on‑the‑spot scribe fits for cabinets. The controlled, low‑vibration blade protects delicate veneer faces.

Creative

Geometric Inlay Wall Art

Lay out a grid or mosaic on a plywood or hardwood panel, then use the segmented blade to plunge and outline recesses for contrasting wood inlays. The Starlock’s low vibration helps keep lines crisp; finish by flush‑trimming the inlays for a seamless surface.

Hidden‑Spline Picture Frames

Assemble simple mitered frames, then plunge cut narrow kerfs across the corners to insert contrasting wood splines for strength and style. Flush cut any proud material and sand for a clean, pro look without a table saw jig.

Custom Vent and Switch Plates

Make wood register covers and switch/Outlet plates by plunge cutting precise rectangles and notches in thin stock. The segmented edge lets you start, stop, and square corners cleanly for a tailored, hand‑made finish.

Live‑Edge Shelf Fitment

Scribe shelves to irregular walls, then nibble away the line with controlled plunge/flush cuts for a tight, built‑in look. Use the blade to flush‑trim wooden cleats and dowels so hardware stays invisible.

Shoji‑Style Tea Light Lantern

Cut window openings and lattice grooves in softwood panels, assemble a box, and flush‑trim any proud joints. Add rice paper or acrylic inside; the oscillating blade’s control keeps thin parts from splintering.