Features

- Dual-Field motor designed for saws to improve cooling and extend motor life

- Lightweight construction (14.2 lb without blade, cord, and wrench) to reduce user fatigue

- Cut-ready depth-of-cut system for quick, accurate depth adjustments

- 51° bevel capacity for a range of angled cuts

- Contoured main handle for improved comfort and control

- Integrated saw hook for secure rafter placement

- Anti-snag lower guard for smoother small cut-offs

- Die-cast aluminum motor and gear housing for durability

- Oil-lubricated gears with relief bellows for extended gear life

- 22 Amp switch with heavy-gauge cord

- Accessible spindle lock for quicker blade changes

Specifications

| Soft Grip | No |

| Dust Blower | Yes |

| Arbor (Inch) | Diamond |

| Spindle Lock | Yes |

| Foot Material | Steel |

| Blade Location | Left |

| Power (Ampere) | 15 |

| Depth Adjustment | Yes |

| Saw Blade (Inch) | 7-1/4 IN. |

| Cord Length (Feet) | 8 ft |

| Tool Height (Inch) | 7.25 IN. |

| Tool Length (Inch) | 19.5 IN. |

| Bevel Capacity (°) | 51° |

| Tool Weight (Pound) | 14.2 lb. |

| Electric Motor Brake | No |

| Gear Housing Material | Aluminum |

| Sawing Capacity At 45° (Inch) | 1-31/32 IN. |

| Sawing Capacity At 90° (Inch) | 2-13/32 IN. |

Related Tools

Related Articles

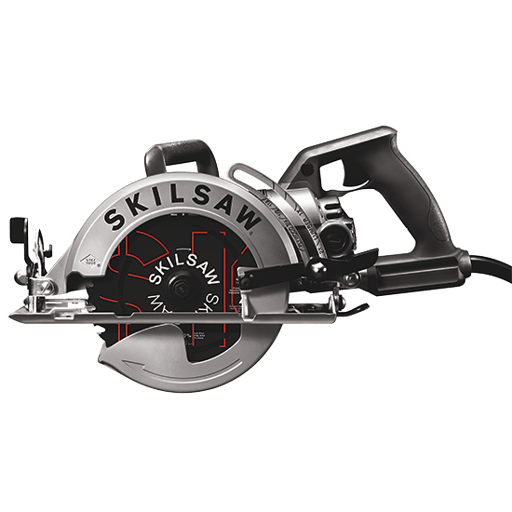

A 7-1/4-inch worm drive circular saw with a Dual-Field motor, designed for durable jobsite use and accurate cutting. The saw includes a 24-tooth carbide blade and a multi-function blade wrench. It is lighter than the prior model and provides features for depth adjustment, bevel cutting, and routine blade changes.

Skil 7-1/4 IN. Worm Drive Review

First impressions

I picked up the Skilsaw worm drive with a clear purpose: long days framing and breaking down sheet goods where torque, line of sight, and durability matter more than ounces. Out of the box, it feels like a real jobsite tool. At 14.2 lb (bare), it’s lighter than older worm drives I’ve used but still has that planted, confident heft. Controls are purposeful, the levers and depth scale are easy to read, and the left-blade layout gives a clean sight line to the cut. If you’ve only used sidewinder saws, the balance and sound will feel different; if you’ve used worm drives before, you’ll feel right at home.

The included 24T carbide framing blade is serviceable for rough work. I swapped in a higher-quality blade for finish-critical tasks, but I appreciate that the saw ships ready to go.

Power and cutting performance

This saw’s Dual-Field motor is the headline feature, and in use it’s not just marketing. I ran it through wet framing lumber, 1-3/4-in. LVL, and stacks of 3/4-in. plywood. It maintains speed under load and doesn’t give up when the cut gets dense or knotty. Worm drive torque is why you buy a saw like this, and the Skilsaw delivers—rips are steady and straights stay straight without feeling like you’re wrestling the tool.

A few performance notes from the field:

- Depth capacity at 90° is 2-13/32 in., which covers 2x stock and most engineered lumber in a single pass. At 45°, you get 1-31/32 in., enough for common compound cuts.

- The anti-snag lower guard actually prevents hang-ups on thin or short offcuts. Plunge cuts for outlet boxes in sheathing were smooth and predictable.

- The dust blower keeps the cut line surprisingly clear for a corded worm drive. There’s no dust port, so you’ll still want a vac for interior work, but the line-of-sight benefits are real.

- Spin-down takes a few seconds because there’s no electric brake. Not a dealbreaker, but it affects your rhythm and requires a bit more patience between cuts.

Noise and vibration are typical worm drive: loud and solid. Wear hearing protection and a good pair of gloves on long days.

Build quality and ergonomics

Skilsaw has leaned into jobsite durability here. The die-cast aluminum motor and gear housing feels tough, and the steel shoe is flat and confidence-inspiring on a straightedge. Steel can bend if you drop it from height—magnesium has an advantage there—but it also tolerates abuse and can be trued if needed. Mine stayed dead-flat after a workweek bouncing between framing and shop cutting.

The handle design is standout for a tool in this class. The contoured main grip and the forward pommel give good control whether you’re ripping, crosscutting, or making long bevels. There’s no soft overmold, but the geometry reduces wrist fatigue and gives you leverage to steer the cut. The saw balances well by the integrated rafter hook, which makes staging on joists and ladders feel secure. The eight-foot heavy-gauge cord is robust and strain-relieved properly; it’s long enough to be useful and short enough to stay out of the way.

Blade-left orientation is a big part of the ergonomics story. As a right-hander, I can watch the teeth meet the line without leaning over the saw or peeking around the guard. Left-handed users might find chips and dust thrown toward their body more often; it’s manageable, but worth noting.

Accuracy and adjustments

The “Cut-Ready” depth-of-cut system is simple and practical. Markings align with common material thicknesses, and the depth lever locks positively without creeping. The bevel range to 51° gives a useful extra bit for back cuts; the scale is legible, and the detents (while not elaborate) are consistent. I checked 0° and 45° out of the box against a reliable square—they were spot on. After a week of cutting, including some not-so-gentle jobsite handling, alignments stayed true.

The shoe glides smoothly across plywood and engineered lumber without scuffing. On finished surfaces, I still throw down painter’s tape to be safe—steel shoes can pick up burrs over time—but out of the gate it’s clean. The anti-snag guard helps when you’re trimming thin rips or finishing cuts near the edge of a workpiece.

Blade changes and compatibility

Access to the spindle lock is excellent, and the onboard multi-function wrench earns its keep. Blade swaps are quick, clean, and require no contortions. The saw uses a diamond arbor, which is standard for worm drive blades; most framing blades include the diamond knockout, and premium options are widely available. If you’re moving over from sidewinders, check your blade stash—some may not fit without the diamond knockout.

Maintenance and longevity

One reason worm drives last is their gear architecture, and Skilsaw doubles down with oil-lubricated gears and relief bellows. It’s easy to check and top off gear oil with basic hand tools, and doing so pays dividends in smoothness and lifespan. I like that the switch is rated generously and the cord is heavy gauge—both are small signs the saw is built for daily work.

I didn’t notice the motor getting hot, even during extended rips. The Dual-Field design seems to do what it claims: better cooling under sustained load. As with any corded saw, brush inspection and routine cleaning will keep it cutting like new.

What could be better

- No electric brake: You’ll wait for the blade to coast to a stop. It’s manageable but noticeable if you’re used to braked saws.

- Weight: At 14.2 lb it’s on the lighter side for a worm drive, but still heavy compared to sidewinders. Overhead work or ladder cuts will remind you of that.

- Steel shoe: Durable and flat, but more prone to bending than magnesium if dropped. Treat it like a precision surface.

- No soft-grip overmold: The contoured handle is comfortable, but gloves help on long sessions.

- No dust collection port: The blower helps with visibility, but this is not the saw you pick for clean interior cuts.

None of these are dealbreakers in the context of what this saw is meant to do. They’re trade-offs that come with the worm drive territory.

Use cases where it shines

- Framing and decking: Long, straight rips in wet 2x, birdsmouths, and repetitive crosscuts are this saw’s home field.

- Engineered lumber: LVL, PSL, and dense stock don’t bog it down.

- Sheet goods: With a straightedge guide, it tracks beautifully through plywood and subfloor.

- Small cutoffs and plunge work: The anti-snag guard and clear sight line make finicky cuts less finicky.

It’s also capable of occasional masonry or stone work with the right blade, but that’s not where I’d spend most of its life. For those tasks, plan for dust and cooling management separately.

Who it’s for

Carpenters, framers, deck builders, and serious remodelers who prefer or require a worm drive will get full value here. If you’re a DIYer who mostly breaks down a sheet or two a month and makes the occasional trim cut, a lighter sidewinder with an electric brake might be a better fit. Left-handers should consider how they like a blade-left saw before committing.

Recommendation

I recommend the Skilsaw worm drive for professionals and committed builders who want a durable, accurate, torque-rich circular saw with thoughtful jobsite features. It cuts with authority, stays cool under load, holds its settings, and has the ergonomics to work all day. The trade-offs—no electric brake, more weight than a sidewinder, and a steel shoe—are real but appropriate for the category. If your work rewards a stable, powerful cut with a great sight line, this saw belongs on your sawhorses.

Project Ideas

Business

Mobile Panel Breakdown Service

Offer on-site plywood and lumber cutting for DIYers and small contractors who lack shop tools. Use a track or straightedge with the worm drive saw for cabinet-grade cuts, charge per sheet or per hour, and upsell delivery. Position as a time-saver that provides square, bevel, and repeatable cuts at job sites.

Deck and Stair Stringer Specialist

Niche service focused on decks, fascia miters, picture-frame borders, and stair stringers. The saw’s torque and 51° bevel capacity make compound miters and stringer notches efficient. Sell fixed-price packages (small patio, mid-size deck) and premium add-ons like waterfall corners and beveled fascia.

Flat-Pack DIY Kits

Produce pre-cut kits—hex shelves, planter boxes, slat benches—using repeatable jigs and the saw’s quick depth and bevel adjustments. Include hardware, sanded parts, and illustrated instructions. Sell on Etsy, local markets, and your site; offer custom sizes and bulk orders for boutiques.

Hands-On Workshops + Tool Affiliate

Run weekend classes where students build a small project (planter or shelf) while learning circular saw safety, guides, and bevel techniques. Monetize through tuition, sponsorships, and affiliate links for blades, guides, and PPE. Provide take-home cut lists and setup cards.

Content + Plans Library

Create short-form videos and PDFs showcasing worm drive tips: bevel setups, kerf management, small cutoff techniques, and jobsite jigs. Sell detailed project plans with cut maps optimized for 7-1/4 in. capacity, offer premium memberships, and license clips to tool retailers.

Creative

Waterfall-Miter Coffee Table

Create a modern coffee table with a continuous-grain waterfall edge. Use the 51° bevel capacity to make precise 45° miters on a glued-up slab under 2-1/2 in. thick. The cut-ready depth system helps dial in exact blade height for clean miters; use a straightedge guide for glue-ready edges and the anti-snag guard for safe small trim cuts.

Hexagon Nesting Shelves

Build a set of hex shelves with 30° bevels for crisp joints. The left-blade visibility makes following a guide easy, while the spindle lock speeds blade swaps between fine-finish and construction blades. Finish in different stains so the shelves can nest or stand alone as a geometric wall feature.

Herringbone Headboard/Accent Wall

Rip and crosscut boards into uniform slats, then trim ends at 45° to assemble a herringbone pattern on plywood backing. The saw’s long cord and saw hook make wall installs easier. Use the depth-of-cut system to score then finish cuts on veneered sheets to reduce tear-out.

Cascading Cedar Planter Trio

Build three mitered planter boxes that step down in size. Cut 45° bevels for seamless corners and use the anti-snag guard for short offcuts. The durable aluminum housing and Dual-Field motor handle outdoor lumber; add a false bottom and drainage slats for longevity.

Floating Shelves with Hidden Cleats

Make thick floating shelves by laminating boards and routing a hidden cleat recess using repeated depth-controlled passes. The cut-ready depth-of-cut system ensures accurate, consistent notches, and the steel foot keeps cuts straight along a clamp-on guide.