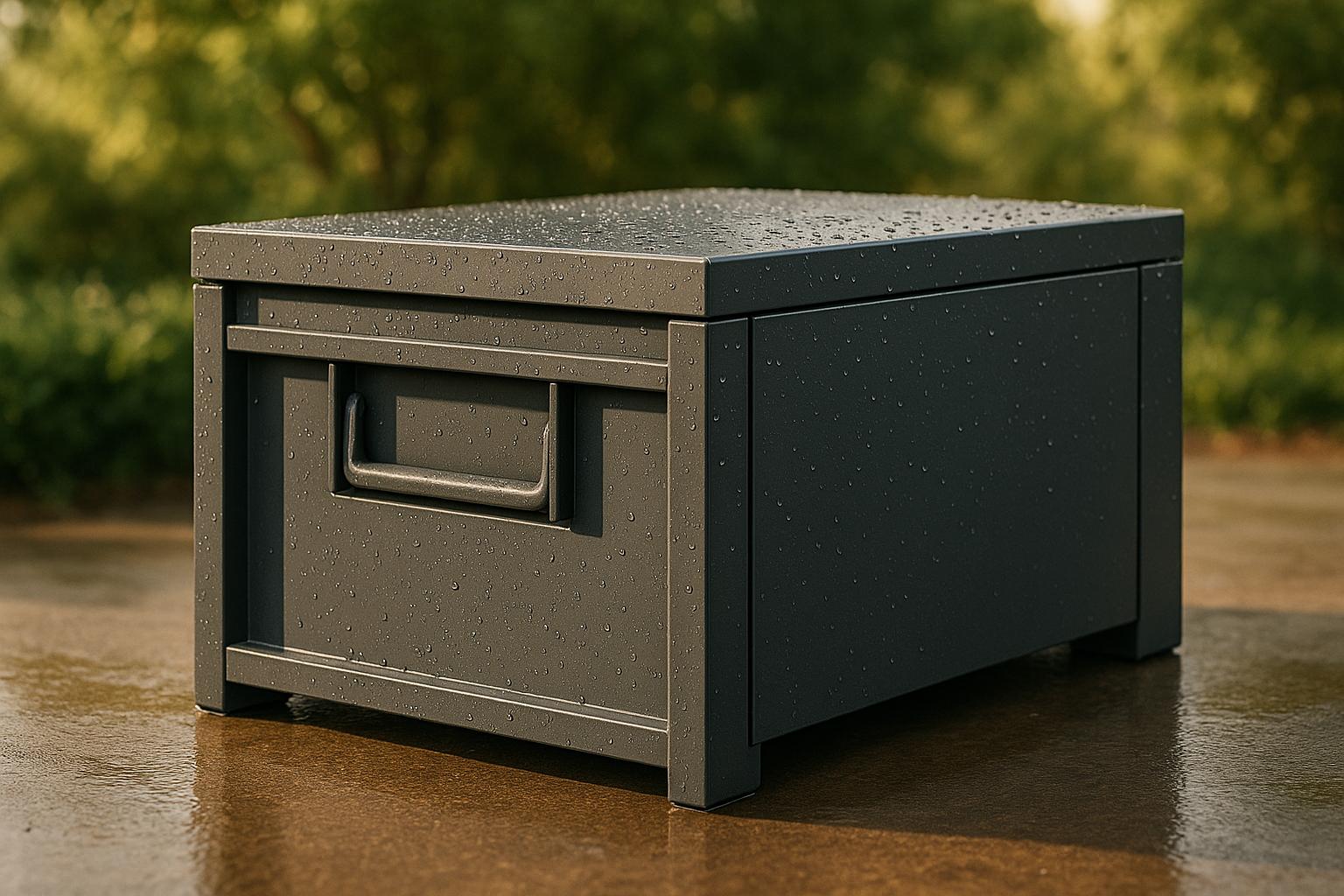

When it comes to protecting your tools, weatherproof storage is a must. Tools exposed to moisture, dust, and extreme temperatures can rust, corrode, or fail, costing you time and money. Investing in proper storage can extend the lifespan of your tools from just a few years to decades. Here's what you need to know:

- Durable Materials: Choose heavy-duty plastic, steel, or aluminum based on your environment. Steel offers strength, aluminum resists corrosion, and reinforced plastics handle impacts and temperature changes.

- Weather-Resistant Seals: Look for IP65 or higher ratings to guard against dust and water. Rubber gaskets and automotive-style seals are key for keeping moisture out.

- Secure Locks: Reinforced locks and multiple locking points protect tools from theft and maintain proper seals.

Options range from truck-mounted toolboxes to jobsite storage boxes and outdoor garden tool sheds. Each type is designed for specific needs, ensuring tools stay safe, dry, and organized. Regular maintenance, such as cleaning seals and monitoring for damage, helps keep your storage effective over time.

Whether you're a contractor or a DIYer, the right weatherproof storage saves money, protects your investment, and keeps your tools ready for action.

RIDGID Pro Tool Box Review One Tuff Tool Box! Water Proof Weather Proof Test 22 in. 25in.

Key Features to Look for in Weatherproof Tool Storage

When you're on the hunt for weatherproof tool storage, three key features stand out as essential for keeping your tools safe and secure. These features - durable materials, effective seals, and secure locks - work together to protect your tools from harsh conditions and potential damage. Let’s break down what makes these features so critical.

Durable Construction Materials

The backbone of any reliable weatherproof storage lies in the materials used to build it. Options like heavy-duty plastic, steel, and aluminum each bring unique strengths to the table, depending on your needs and environment.

Plastic and Polymers: High-impact plastics, such as structural foam, are designed to handle drops, impacts, and extreme temperature changes. For instance, the Milwaukee PACKOUT system is made from impact-resistant polymers with metal-reinforced corners, capable of supporting up to 100 lbs[1].

Steel: If you're looking for strength and durability, steel is a solid choice - especially for stationary or truck-mounted storage. Many steel options, like the Tool Vault Portable Weather Resistant Tool Box, use 16-gauge steel with a powder-coat finish to resist rust and corrosion[5].

Aluminum: Aluminum combines strength with a lighter weight, making it ideal for mobile storage solutions. Its corrosion resistance also makes it a smart pick for environments with frequent moisture exposure.

Choosing the right material depends on your conditions. For heavy-duty use, reinforced plastic with metal corners is a great option. If you're dealing with constant moisture, powder-coated steel or treated aluminum will hold up best.

Weather-Resistant Seals

Even the toughest materials can’t protect your tools if the storage doesn’t have quality weather-resistant seals. These seals keep out water, dust, and debris, preventing rust and extending the life of your tools.

IP Ratings Matter: Products with clear IP (Ingress Protection) ratings are your best bet. For example, an IP65 rating ensures the storage is dust-tight and protected from water jets, making it perfect for rainy or dusty worksites. The Milwaukee PACKOUT Large Tool Box features an IP65-rated seal to keep out rain and debris[1].

For Extreme Conditions: If you need extra protection, look for IP67-rated products like the Monoprice Weatherproof Hard Case. These can handle full submersion in water up to one meter deep[2].

Sealing Materials: High-quality rubber gaskets and weatherproof seals are essential. They need to stay flexible in extreme temperatures, whether it's freezing cold or scorching heat, without cracking or losing their effectiveness. Automotive-style bulb seals, often found in truck toolboxes, compress tightly when closed, creating a watertight barrier that holds up under pressure[3].

Effective seals are the unsung heroes of weatherproof storage, keeping your tools clean, dry, and ready for action.

Secure Locking Mechanisms

A good weatherproof storage solution doesn’t just protect your tools from the elements - it also guards them against theft. Secure locking mechanisms are vital for both security and maintaining a proper seal in challenging environments.

Reinforced Locks: Look for metal-reinforced or armored locks that can handle tough conditions while deterring theft. DECKED tool boxes, for example, feature armored locking mechanisms that are built to last in extreme environments[4].

Multiple Locking Points: Some high-end options include multiple locking points around the storage unit. This design distributes stress evenly and helps maintain a tight, weatherproof seal.

Extra Security Features: Locks with double-cut keys and reinforced lock cylinders provide an added layer of protection. The Tool Vault system incorporates locking latches with double-cut keys, ensuring both security and a dependable seal[5].

When choosing a locking mechanism, make sure it’s built to resist corrosion and won’t seize in wet or freezing conditions. A reliable lock not only keeps your tools safe but also ensures quick and hassle-free access when you need them most.

Types of Weatherproof Tool Storage Solutions

When it comes to keeping your tools safe from the elements, the right weatherproof storage option depends on your specific needs. Whether you're transporting tools in your truck, tackling construction projects, or organizing your garden tools, there's a storage solution designed to handle the challenges of each environment.

Truck Toolboxes

Truck toolboxes are the go-to choice for mobile tool storage. Built to endure constant movement and harsh weather, these boxes are mounted directly onto your truck and come in various configurations to suit your workflow.

Top mount toolboxes are a popular pick, featuring drop-down doors and automotive-style bulb seals that keep water out. These boxes typically measure between 72" and 96" in length, 13" to 16" in depth, and 16" to 24" in height. They’re made from .125-inch aluminum, available in diamond plate or smooth finishes, offering durability without adding too much weight[3].

For those needing more space, crossover boxes span the width of the truck bed and often come with IP65 weather ratings, providing professional-grade protection against dust and water[1]. Side-mount and underbody toolboxes offer added flexibility, with lengths ranging from 18 inches to 120 inches and various configurations to suit different access needs - all while maintaining reliable weatherproof seals[3].

Premium options like the DECKED Tool Box take it a step further with features such as a watertight gasket seal and a spring-loaded top door for smooth operation. With 73.4 gallons of internal space, it’s a modern take on truck storage[4]. For those who prioritize organization, pull-out drawer units like the PACK RAT® Model 338-5 offer a 425lb drawer load capacity and a 750lb top load capacity, crafted from heavy-duty 14-gauge steel with reinforced 12-gauge skids[8].

For rugged construction site demands, jobsite storage boxes might be a better fit.

Jobsite Storage Boxes

Construction sites are tough on tools and storage, which is why jobsite storage boxes are built to handle the abuse. These boxes are designed to withstand extreme conditions, frequent relocation, and rough handling.

Constructed from 14-gauge steel with fully seam-welded corners, these boxes are built for strength and durability. The automotive bulb-style seals keep out moisture and dust, while lockable lids and forklift slots make them secure and easy to transport around the site[3][7].

A standout example is the Tool Vault TV-ME3015, which combines 16-gauge steel construction, welded seams, and a water-resistant seal with a locking latch featuring double-cut keys. Its high-gloss powder coat finish adds extra corrosion resistance for long-term use[5]. Sizes vary widely, with lengths ranging from 18" to 36", depths from 18" to 24", and heights from 18" to 48"[3].

What makes jobsite boxes unique is their ability to work in both stationary and mobile settings. Features like double side handles and triangle locking mechanisms ensure tools stay secure, even when the box is moved frequently. Their heavy-duty build resists impacts, weather, and rough treatment while maintaining their weatherproof performance[7].

Outdoor Storage for Garden Tools

Garden tools face a different set of challenges - damp conditions, UV exposure, and long periods of inactivity. Weatherproof garden storage solutions are designed to address these issues while keeping tools organized and ready for use.

Sheds, bins, and cabinets made for garden tools focus on ventilation to prevent moisture buildup, while foam bulb seals and powder-coated finishes keep water out[3]. Unlike jobsite boxes, which prioritize impact resistance, garden storage emphasizes rust prevention and moisture control since tools often remain unused for extended periods.

These systems are designed with vertical organization and wide doors to accommodate long-handled tools like rakes and shovels. Drainage systems are often included to manage wet tools without creating standing water. Materials like treated wood, resin, or lighter gauge metals are commonly used, balancing weather resistance with affordability.

Because portability isn’t a primary concern, garden storage solutions can be larger and more stationary. This allows for added capacity and specialized features such as tool hangers, shelves, and compartments for items like fertilizers, seeds, and seasonal equipment. These designs ensure that even tools left outdoors stay dry, organized, and protected throughout the year.

How to Choose the Right Tool Storage for Your Needs

The right tool storage isn’t just about convenience - it’s about protecting your tools, saving money, and making your work more efficient. Your workspace, the number of tools you own, and how often you use them all play a role in choosing the best option.

Assessing Your Tool Collection

Start by taking stock of what you own. Count your tools and measure their dimensions. Interestingly, more than 60% of workshops now favor clear polystyrene (PS) toolboxes for their visibility and moisture protection, which helps streamline workflows [9]. Keep in mind that power tools, like drills and circular saws, are bulkier and often require more protection from moisture. For example, drills typically need storage that’s at least 12" x 10" x 4", while circular saws require something closer to 18" x 12" x 8". Garden tools, with their long handles, often need vertical storage solutions.

Also, think about how much weight your storage needs to handle. If you’re storing heavy tools, look for higher-capacity options that can bear the load. Tools you use daily should be easy to access, while seasonal or rarely used items can go in less convenient compartments.

For a more organized approach, platforms like Toolstash can be a game-changer. They offer digital inventory tracking, smart categorization, and location tracking to help you manage your tools and minimize losses.

Once you’ve assessed your collection, the next step is to factor in how your local weather affects your storage needs.

Evaluating Weather Challenges

Your climate plays a huge role in determining the kind of storage you need. If you live in a rainy area, look for toolboxes with at least an IP65 rating to protect against water and debris. For areas prone to flooding or work near water, IP67-rated options like the Monoprice Weatherproof Hard Case can keep your tools safe even if submerged up to one meter [2].

Extreme temperatures are another concern. If you live in a region where temperatures regularly dip below 20°F or climb above 100°F, you’ll need storage with thermal protection. Plastic storage can become brittle in freezing temperatures, while metal boxes may cause condensation during sudden temperature changes.

Humidity is a silent threat that can lead to rust and corrosion. If you’re in a coastal region, a high-humidity area, or working in poorly ventilated spaces, choose storage solutions with rust-resistant materials, rubber gaskets, and drainage systems [9][6]. For specific scenarios, like storing tools in unheated garages or truck beds overnight, extra protection is essential.

Once you’ve addressed weather-related risks, think about how often you need to transport your tools.

Considering Mobility and Accessibility

Your mobility needs should guide your choice of tool storage. If you’re frequently on the move, prioritize portable and easily accessible options [4][5].

Modular systems like Milwaukee's PACKOUT are a great choice for flexibility. You can customize and expand these systems as your tool collection grows [1]. They’re particularly useful for mixed work environments - leave the base units stationary and take only what you need for specific tasks.

For mobile work, look for toolboxes with reinforced handles and balanced weight distribution to make transportation easier [1][5]. Truck-mounted storage offers high capacity and portability but requires permanent installation. On the other hand, jobsite storage boxes provide modularity for contractors who work across multiple locations without needing to modify their vehicles.

How you access your tools also matters. If you need them daily, shallow, top-opening compartments can save you from digging through deep boxes. Side-opening storage is great for tight spaces, but it might not offer the same level of weather protection.

Finally, don’t forget to measure your workspace. Outdoor tool storage ranges in size from 18" to 96" in length, 13" to 24" in depth, and 16" to 48" in height [3]. Be sure to account for door swings and clearance - there’s no point in buying a 96" box if it won’t fit in your garage or truck bed.

Maintenance and Organization Tips for Weatherproof Tool Storage

Even the most durable weatherproof storage needs proper upkeep to stay effective. A little routine care and thoughtful organization can go a long way in extending the life of your storage unit and keeping your tools in excellent shape.

Regular Cleaning and Inspections

Make it a habit to inspect your storage every few months or after harsh weather conditions. Empty the unit, wipe down all interior surfaces, and check for any signs of wear or damage. Pay close attention to seals, latches, and hinges - these are critical for keeping moisture out.

Seals and gaskets are your first defense against water. Look for cracks, tears, or any hardening in the rubber. Even minor damage can compromise the unit’s weatherproof capabilities. For example, if you’re using truck toolboxes with bulb seals, like those from RC Industries, inspect the seal-to-frame contact for gaps or wear[1][3].

Don’t forget the exterior. UV exposure can weaken plastic components and cause metal parts to rust. Keeping your storage in a shaded spot can help reduce these risks and minimize temperature fluctuations[2]. Once cleaned, reorganize your tools to keep everything efficient and easy to find.

Organizing Tools for Accessibility

A well-organized storage system saves time and protects your tools. Start by grouping tools based on how often you use them - keep daily essentials within easy reach and tuck away seasonal items in less accessible spots[4].

Using interior trays and dividers can make a big difference. Systems like Milwaukee PACKOUT™ offer modular trays that let you customize compartments to fit your tool collection perfectly[1]. These setups not only keep tools organized but also prevent them from shifting during transport.

For added efficiency, consider digital tools like Toolstash to track inventory and categorize items. Clear labeling is also a must. Weather-resistant labels and color-coded sections can make it simple for anyone accessing the storage to find what they need. Plus, a tidy system helps reduce clutter, which can trap moisture.

Preventing Moisture Buildup

Moisture is the enemy of long-lasting tools, and managing it is essential. Condensation can form quickly, especially when a cold toolbox is brought into a warm environment. To combat this, place silica gel desiccants inside your storage and replace them regularly[2].

When opening your toolbox, let it air out briefly before sealing it again. For permanent installations, like truck toolboxes, check that drain holes are free of debris to allow proper drainage.

Maintaining stable temperatures is another key step. If you store tools in an unheated garage or truck bed, consider extra moisture-control measures to prevent condensation.

Taking a few minutes every few months to clean, organize, and inspect your storage can save you from expensive repairs or replacements. These simple steps ensure your tools are always in top condition and ready to go when you need them most.

Conclusion

Choosing the right weatherproof tool storage comes down to three main factors: durability, weather resistance, and functionality. The decision you make today not only determines how well your tools are protected but also how efficiently you can work in the long run.

High-quality weatherproof storage with IP65 or IP67 ratings offers solid protection against moisture, dust, and tough jobsite conditions[1][2]. Opting for professional-grade protection can extend the lifespan of your tools significantly - potentially lasting decades instead of just a few years.

Sturdy construction is another must-have. Features like welded seams, reinforced corners, and automotive-style bulb seals add resilience to withstand daily wear and tear as well as extreme environments[1][3][5]. While these systems may come with a higher upfront cost, they often include limited lifetime warranties, making them a worthwhile investment over time[1].

Consider not just the value of the tools you’re safeguarding but also the potential costs of downtime caused by damaged or lost equipment. Investing in reliable storage minimizes these risks, saving you money and headaches in the long run.

Don’t overlook maintenance. Regularly checking seals, gaskets, and other components is essential to keeping your storage in top shape. Pair that with smart organization - like using interior trays and moisture control solutions - and your tools will stay protected for years.

Ultimately, the best storage solution is one that fits your specific needs while delivering essential weatherproofing features. Equip yourself with storage that keeps your tools safe, organized, and ready for peak performance whenever you need them.

FAQs

What are the advantages of using weatherproof tool storage in different environments like construction sites or backyards?

When it comes to protecting your tools, weatherproof storage is a game-changer. On construction sites, it acts as a shield against harsh conditions like pouring rain or blistering heat. This protection helps prevent rust, corrosion, and other damage that can shorten the life of your tools. In the long run, this means fewer replacements and more money saved.

In home settings like backyards or gardens, weatherproof storage ensures your tools are safe from rain, sun, and humidity. This keeps them in great shape, ready for any outdoor project. Plus, with features like inventory tracking and location management offered by platforms such as Toolstash, staying organized and keeping your tools within easy reach becomes a breeze.

What IP rating should I choose for my tool storage to protect against my local weather conditions?

When choosing weatherproof tool storage, pay close attention to the IP rating (Ingress Protection rating). This rating tells you how well the storage can handle exposure to elements like dust and water. The first number in the IP rating measures protection against solid particles (such as dust), while the second number shows how resistant it is to moisture (like rain or water splashes).

If you’re in an area prone to heavy rain or high humidity, aim for a storage option with a higher second digit, such as IP65 or above, to ensure it can handle wet conditions. On the other hand, if you live in a dusty region, focus on a higher first digit, like IP6X, to keep your tools free from debris. By considering your local weather conditions, you can pick a storage solution that protects your tools and keeps them in great shape all year long.

How can I maintain my weatherproof tool storage to keep it durable and effective?

Keeping your weatherproof tool storage in good shape requires regular care. Start by giving it a periodic wipe-down with a damp cloth to clear away dirt, dust, and debris. Skip the harsh chemicals - they can harm the protective weatherproof coating.

Next, take a close look at the seals, locks, and hinges. These parts are essential for keeping out moisture and dust, so check for any signs of wear or damage. If the hinges or locks are sticking or showing signs of rust, a little lubricant can go a long way in restoring smooth operation. For storage units braving the outdoors, inspect for cracks or warping and address any problems quickly to ensure the unit stays protective.

Inside, organization and dryness are just as important. Keep things tidy and use moisture-absorbing products like silica gel packs to ward off condensation and rust, keeping your tools in top condition.