Features

- Lawn Mower Blade Sharpener : The new version of the Lawn Mower Blade Sharpener is Made of corundum, it solves the base wear caused by the excessive speed of grindstone, and effectively prolongs the service life and improves the use effect of the product. Our lawn mower blade sharpener is provided by the original factory, and it is guaranteed.

- Lawnmower Blade Sharpener for Drill : Lawn mower blade sharpener could be used to sharpen mower blades to make the blade sharp again. Using in sharpening lawn blades, lawn tractors, mowers, rototillers, drill blades, sickle bar cutters, etc. Fit for most power drills (Do not need to buy expensive blades).

- Easy to Use : It only takes 10s to install it. You only need to install it on your electric drill to use it. And it can quickly make blunt old blades sharper. Effectively provide your productivity. Fast, automatic, easy, safe, and saves time and effort.

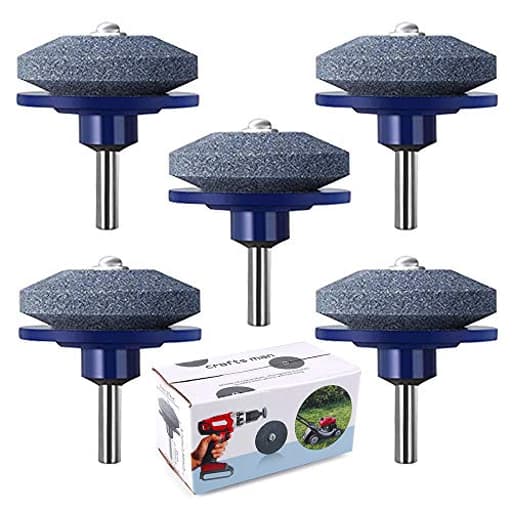

- Size & Package: Each sharpener measures 50 x 47 mm / 1.97 x 1.85 inches, with slight variations possible due to manual measurement. The package contains 5 lawn mower blade sharpeners, each in an attractive box.

- Keep your lawnmower blades sharp with a lawn mower blade sharpener. It's a must-have for any lawn mower or tractor. Enjoy faster, easier mowing and save time. A practical tool for everyday use.

Specifications

| Color | Dark Blue |

| Unit Count | 5 |

Corundum grinding sharpeners that mount to a standard power hand drill for restoring cutting edges on lawn mower blades and similar implements. Each 50 x 47 mm unit installs in about 10 seconds, fits most drills, resists wear at high speeds to prolong service life, and is sold in a pack of five.

cenoz Crafts Man Lawn Mower Blade Sharpener for Any Power Hand Drill by Review

What it is and who it’s for

The cenoz drill-mounted blade sharpener is a simple idea done reasonably well: a small corundum grinding wheel that chucks into a standard drill to refresh mower blades and similar cutting edges. It comes as a five-pack, each unit roughly 50 x 47 mm, so you’ve got backups on hand. If you maintain a push mower or lawn tractor and want a quick way to restore a serviceable edge without a bench grinder or belt sander, this little sharpener hits a sweet spot between convenience and acceptable results.

I tested it on a 21-inch push mower blade that had dulled over a month of spring growth, a set of twin blades from a lawn tractor with moderate wear, and one intentionally abused blade with a couple of small nicks. I used both a corded 3/8" drill and a mid-torque cordless drill to see how speed and torque affected the process.

Setup and build quality

Installation is about as painless as it gets: chuck the shank into a drill and you’re ready in seconds. The stone is corundum, and the hub design helps you hold a consistent angle on a mower blade’s bevel. It’s not a precision jig, but the geometry naturally encourages a repeatable approach, which is half the battle with mower edges.

Fit and finish are utilitarian. The stone was true enough out of the box—no noticeable wobble—and the shank ran concentric in my drills. The plastic and metal components felt adequate for light to moderate duty. It’s not a lifetime tool; it’s a consumable. That’s the point of the five-pack.

Two notes on setup that matter in practice:

- Use a corded drill or a high-capacity cordless. Spin consistency matters more than peak RPM.

- Secure the blade in a vise. Trying to sharpen on the mower is a recipe for poor angles and safety issues.

Sharpening performance

On a typical dull mower blade (rounded edge, no major dings), the sharpener did exactly what I hoped: it restored a clean, consistent bevel in a few passes. I could see a uniform grind line along the cutting edge, with no gouging or uneven bite. That consistency is tough to match freehanding with a bench grinder.

Time-wise, a single push mower blade took me roughly 3–5 minutes from first pass to a working edge. Tractor blades with more surface area and wear took closer to 8 minutes each. Heat was manageable because I kept pressure light and worked in short bursts, letting the stone do the cutting. The result wasn’t razor-sharp (you don’t want that for mower blades anyway), but it was more than adequate for a clean cut and noticeably improved mowing quality on the next pass across the yard.

Where the sharpener slowed down was in removing deeper nicks. It will eventually smooth mild edge damage, but it’s not the fastest tool for that. If your blade has hit stones or has quarter-inch chips, you’ll either spend a while grinding or you’ll do a rough reprofile with a grinder or file first, then finish with this. That’s not a knock; it’s simply the reality of a small, drill-powered stone.

Technique matters

Like a lot of affordable sharpening solutions, the results depend on your approach. Here’s what worked well for me:

- Use moderate speed. Somewhere in the middle of your drill’s range keeps the stone cutting without overheating. Full throttle on a high-speed drill can glaze the stone and shorten its life.

- Keep passes short. Tap the edge with the stone, pull away, let it spin up, repeat. Light, overlapping strokes beat continuous heavy pressure.

- Follow the factory bevel. The stone’s profile nudges you to the right angle, but don’t fight the blade’s original geometry.

- Refresh, don’t reprofile. For seasonal maintenance and mid-season touch-ups, it shines. For rebuilding a wrecked edge, use a coarser tool first.

- Balance the blade after sharpening. Hang the blade on a nail or balancer; if one side dips, take a couple of quick passes on the heavier side. Balanced blades cut cleaner and reduce vibration.

I also found corded power better for maintaining consistent RPM on longer sessions. My 5.0Ah cordless handled one or two blades fine; more than that and it slowed just enough to affect cut rate.

Durability and wear

Corundum is a reasonable choice here: it’s hard, holds up decently at drill speeds, and doesn’t shed too quickly with proper technique. After sharpening two push mower blades and touching up one tractor blade, my first stone showed normal wear with plenty of life left. The edge of the stone remained crisp enough to hold angle guidance. I did not experience cracking or center slippage, but I can see how excessive side pressure or continuous, high-speed use could heat-soak the hub and accelerate wear.

If you treat it like a small grinding wheel instead of a brute-force solution—light pressure, intermittent contact—it lasts longer and cuts better. The upside of the five-pack is you don’t feel compelled to wring every last millimeter out of a single stone; swap when the face gets glazed or the profile loses its bite.

Safety and ergonomics

It’s easy to forget that a drill and a small stone can still make a mess of things. Eye protection is a must, gloves are smart, and hearing protection isn’t a bad idea. Unplug the mower or pull the spark plug wire and remove the blade; don’t try to sharpen under the deck. Clamp your work firmly.

Ergonomically, the form factor is friendly: one hand on the drill, the other resting the blade or the vise jaw for stability. There’s no heavy wheel to wheel around and no sparks showering your bench.

How it compares to other methods

- Bench grinder: Faster material removal and long-term durability, but it takes a steadier hand to maintain a straight, consistent bevel, and it can chew through metal quickly if you’re heavy-handed. For major repairs, the grinder wins. For routine touch-ups, the drill-mounted stone is less hassle.

- File or stone: Great control, low heat, and inexpensive, but slower—especially on hard steel or larger blades. The cenoz sharpener is appreciably faster.

- Angle grinder with flap disc: Very fast and versatile, but easy to overdo and tricky to hold a consistent angle unless you’re practiced. Also more aggressive than you need for routine maintenance.

The cenoz sits in the “maintenance touch-up” lane and does well there.

Value

The five-pack is the clincher. One stone gets you through multiple sharpening sessions with proper technique. Having spares on the shelf means you can swap out if you glaze a face or ding a corner. Compared to the cost of a bench grinder and the space it occupies, or the learning curve of an angle grinder, this is a low-commitment way to keep blades in working order.

Limitations to consider

- Not ideal for heavy damage or regrinding a new bevel angle.

- Dependent on drill quality and speed stability.

- Like any small stone, it can glaze with too much heat or pressure; technique matters.

- The guided profile helps with angle, but it’s not a rigid jig—user control still counts.

None of these are deal-breakers for the target use case, but they’re worth knowing.

The bottom line

I came away impressed by how consistently the cenoz sharpener refreshed mower blades with minimal setup and very little fuss. It’s not a miracle cure for battered edges, and it won’t replace a grinder if you regularly rehab neglected blades. But for routine maintenance—the kind that keeps your mower cutting cleanly and reduces strain on the engine—it’s quick, predictable, and friendly to use.

Recommendation: I recommend this sharpener to homeowners and DIYers who want an easy, drill-powered way to maintain mower blades through the season. It’s a fair value as a five-pack, installation is fast, and with a bit of patience and light pressure, it delivers a clean, consistent edge. If you routinely deal with heavily damaged blades or run a high-volume sharpening routine, you’ll want a bench grinder or belt sander in the mix and keep this as a convenient touch-up tool.

Project Ideas

Business

Mobile Mower Blade Sharpening Service

Offer quick on-site blade sharpening using the drill-mounted sharpeners. Operate a van or trailer that visits neighborhoods, parks or HOAs with a per-blade or flat-rate price. Promote seasonal tune-ups, quick turnaround (10–15 minutes per mower), and bundle with blade balancing and visual inspections.

Landscaper Add-On Service

Partner with local lawn care and landscaping companies to provide an in-house sharpening option. Train crews to use the tool for efficiency; offer contract pricing for regular maintenance of client mowers and fleet equipment to improve cut quality and reduce fuel/time costs.

Retail Sharpening Kits + Workshops

Package the 5-pack sharpeners with safety gear (goggles, gloves), a simple jig, and a printed/QR-code video guide. Sell kits online or through garden centers. Run weekend workshops teaching safe sharpening techniques, blade care, and minor repairs to generate retail sales and recurring customers.

Subscription Fleet Maintenance Program

Target property managers, rental equipment companies and small municipalities with a scheduled sharpening/subscription plan. Provide regular visits, blade replacement forecasting, and maintenance reporting. Predictable recurring revenue and reduced downtime for clients make this attractive for B2B sales.

Content & Affiliate Sales Channel

Create short, shareable videos demonstrating dramatic before/after blade sharpening, quick tips, and tool setups. Monetize via ads, affiliate links to drills and sharpeners, sponsored posts, and driving viewers to paid how-to workshops or local service bookings. Use time-lapse and clear call-to-actions to grow followership.

Creative

Refurbish Vintage Garden Tools

Collect old hoes, sickles, scythes and hand cultivators at flea markets or yard sales. Use the corundum drill-mounted sharpener to restore clean, consistent bevels quickly, then sand and oil wooden handles, add new leather wraps or paint for a vintage look. Result: functional, display-quality garden tools you can keep or sell at craft fairs.

Upcycled Blade Yard Sculptures

Turn retired mower blades and metal scraps into industrial garden art. Use the sharpener to refine edges and remove burrs before bending, welding or bolting pieces together. Finish with rust converters, powder coat, or clear sealer for dramatic weatherproof sculptures, wind spinners or fence accents.

Custom Mower-Blade Utility Knives & Tools

Transform decommissioned mower blades into heavy-duty utility blades, bottle openers, or multi-tools. The sharpener gives a quick, even edge for functional prototypes; add custom handles from hardwood or recycled materials and seal them. Great for maker markets and gifts for outdoor enthusiasts.

Garden Tool Gift Sets

Make polished mini-tool sets for gardeners: sharpened hand trowel edges, small shears and pruners, paired with personalized plant markers and a care card. Use the drill sharpener to keep each metal piece razor-ready. Package in rustic boxes for farmers’ markets or subscription box add-ons.

Edge-Ready Metal Stencils & Plant Markers

Cut metal blanks into shapes for plant markers and decorative garden labels, then use the sharpener to deburr and create razor-sharp stamped edges for crisp impressions. Paint and weatherproof them; offer personalized stamping or hand-lettering for boutique garden shops.