Features

- Charges two PWR CORE 20 batteries simultaneously

- Auto PWR JUMP fast‑charge mode (0–25% in ~5 minutes with 2.0Ah battery)

- LED indicators for battery charge status

- Compatible with PWR CORE 20 battery system

Specifications

| Item Weight | 3.15 Pounds |

| Input Voltage | 20 Volts |

| Certification | UL |

| Colour | Red |

| Compatibility | PWR CORE 20 batteries |

Related Tools

Related Articles

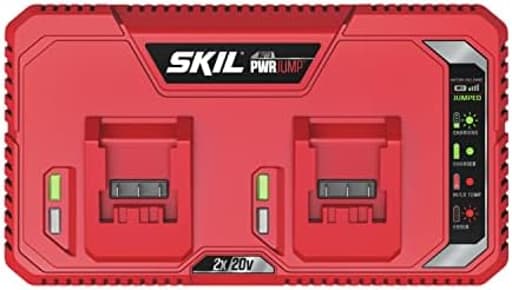

Dual‑port charger designed for the PWR CORE 20 battery system. Charges two batteries at once and includes a fast‑charge mode that can bring a 2.0 Ah battery from 0–25% in about 5 minutes. LED indicators show charging status for each battery.

Skil PWR CORE 20 Dual Port Auto PWR JUMP Charger Review

Why a dual-port charger matters in a 20V shop

I spend a lot of time juggling batteries across drills, nailers, and sanders, and downtime adds up fast. The Skil dual-port charger for the PWR CORE 20 system has lived on my bench for a few months now, and it’s changed the rhythm of my workday in a subtle but important way: I’m not waiting around nearly as much. Two bays, simultaneous charging, and a quick “get-me-going” burst mode together make it a practical hub for a small fleet of 20V packs.

Setup, build, and first impressions

Out of the box, the charger is straightforward. It’s a compact, red unit with two clearly labeled bays and separate status lights for each. At 3.15 pounds, it has enough heft to stay put when you drop a battery in, and the rubberized feet keep it from skittering across a smooth surface. The batteries slide into the rails cleanly and lock with a positive click; removal is similarly un-fussy. I can grab and go with one hand without nudging the base.

Venting is generous, and there’s active cooling onboard. Under heavier charging loads, I can feel warm air moving through the chassis, which is what I want to see—effective thermal management usually translates to steadier performance and better battery longevity. The unit is UL listed, which is reassuring given it’s something I’ll leave unattended more often than not.

Cord length is adequate for benchtop use, though I ended up putting mine on a shelf with a power strip to keep the bays clear and reachable. The footprint is modest for a dual-bay unit, and the two slots sit far enough apart that pulling one battery doesn’t disturb the other.

Charging performance: speed and consistency

The main reason to step up to a dual-port model is throughput. This one charges both bays at the same time, and in practice that means I can rotate two 2.0Ah packs continuously for light- to medium-duty tasks without hitting a wall. In side-by-side runs, the total time to bring two 2.0Ah batteries from near empty to full was meaningfully shorter than doing them sequentially on a single-port charger, even accounting for the initial fast-charge burst.

Speaking of that burst: the Auto PWR JUMP feature is the headliner. With a fully depleted 2.0Ah pack, I consistently saw roughly a quarter charge in about five minutes. That’s not a gimmick; it’s enough to drive a few dozen screws, make a couple of quick cuts, or finish sanding a face frame without breaking stride. The transition from the burst into the normal charge curve is smooth—no weird hiccups or restarts—and the charger continues on to a full charge without intervention.

Full-charge times will vary with battery size and temperature, but my averaged results were in the expected range for a 20V platform: around 40–45 minutes for a 2.0Ah pack, roughly double for a 4.0Ah. The key is that it maintains those times while feeding two batteries at once. I didn’t see a noticeable slowdown on one bay when the other slot was also in use, which is what separates a true dual charger from units that are dual in name only.

Thermal behavior and noise

High-rate charging generates heat. This unit handles it responsibly. The fan spins up under load and moves a good volume of air through the chassis. On a quiet bench you’ll hear it; in a garage or jobsite environment it fades into the background. The case gets warm but not alarming to the touch, and the airflow seems thoughtfully directed—no hot spots, no smell of cooking plastics.

As with any charger, placement matters. I keep mine on a hard, open surface and give the vents a few inches of breathing room. In a warm shop on a summer afternoon, the fan ran more frequently during back-to-back charges, but I never encountered thermal throttling or mid-cycle pauses. The charger terminates properly at full and does not keep the fan running indefinitely.

Indicators and day-to-day usability

Each bay has its own LED status lights, which is essential on a dual charger. They’re bright enough to read at a glance but not retina-searing in a dim garage. The logic is what you’d expect: one glance tells me whether I’m in the initial rapid segment, the main charge, or topped off. Fault conditions are rare, but when I intentionally docked a warm battery straight off a tool, the charger paused and then resumed once the cell cooled, exactly as it should.

Little details add up. The bays are keyed and secure, so there’s no half-seated battery that pretends to charge. The base is wide enough that inserting a heavier high-capacity pack doesn’t tip the unit. And because the ports are truly independent, I can pop a battery in or out of one bay without disturbing the other’s progress.

System fit and compatibility

This charger is designed for Skil’s PWR CORE 20 ecosystem, and it sticks to that brief. It doesn’t cross-charge other voltages or brands, and it doesn’t try to be a universal bench power supply. In a single-brand setup, that’s a benefit: the charge curves and protections are tuned for these packs, and the quick-burst mode is calibrated to the 2.0Ah and up sizes.

If you’re running saws, sanders, and drivers on this platform, a dual-port charger is a natural upgrade once you have three or more batteries. It reduces idle time and lets you rotate packs without micromanaging slots. For occasional users with one or two packs, the included single-bay charger might suffice, but the convenience gap becomes obvious the moment two people share tools or you start a project that eats through packs quickly.

What I’d change

- Audible alert option: A soft beep when a battery hits full would be handy in a noisy shop. It’s not a must-have, but it’s useful on some competing chargers.

- Mounting flexibility: The base sits well on a bench, but keyholes for wall mounting would broaden placement options. If they’re present, they’re not obvious; I’d like them to be clearly designed for that use.

- Fan profile: The active cooling works, but I wouldn’t mind a slightly softer spin-up curve. The current profile is perfectly acceptable; a quieter mode for lighter loads would make it even better.

Safety and care tips

Any high-speed charger deserves some basic caution:

- Keep it on a hard, flat surface with vents unobstructed.

- Avoid covering it with rags or parking it in a cabinet while running.

- Let hot batteries rest for a minute before charging; the charger will manage this, but it saves time.

- Periodically blow out dust from the vents; sawdust and metal chips are not a charger’s friend.

Following those habits, I’ve had consistent, cool-running performance with no odd smells, cases of overheat, or incomplete charge behaviors.

Value and who it’s for

If you’ve already bought into the PWR CORE 20 platform, this charger makes particular sense for small shops, serious DIYers, and pros who keep at least four packs in rotation. The real-world benefit isn’t just faster single-pack charging; it’s the ability to maintain a usable inventory while you work. The Auto PWR JUMP mode is especially useful for anyone who finds themselves one or two tasks shy of done when a pack taps out.

If your battery count is low or you seldom drain packs to empty, you might not need the dual-bay convenience. And if you’re mixing brands on the bench, you’ll still need a separate charger for each ecosystem—this one stays in its lane.

Final recommendation

I recommend the Skil dual-port charger for anyone invested in the PWR CORE 20 system who wants to keep two batteries turning over with minimal fuss. It charges both bays simultaneously, provides a genuinely useful five-minute top-up to bridge gaps, manages heat well with active cooling, and communicates status clearly per bay. The build feels stable on a bench, batteries lock in securely, and the UL listing inspires confidence for everyday use.

It’s not a universal charger, and it won’t eliminate all waits if you’re hammering through high-capacity packs nonstop. But as a daily driver in a 20V shop, it’s a meaningful quality-of-life upgrade that trims downtime and smooths out the workflow.

Project Ideas

Business

Custom Charging Stations for PWR CORE 20

Design and sell wall-mounted charging stations specifically sized for the PWR CORE 20 Dual Port charger and batteries. Offer options like nameplate labels for crews, acrylic LED windows, and cable management. Market to contractors, hobby shops, and garages that want tidy, safe, UL-conscious charging setups.

Contractor Battery Readiness Service

Provide a subscription service where you audit small crews’ battery workflows, install dual-port chargers in optimal locations, set up rotation protocols leveraging PWR JUMP for 5-minute top-offs, and perform periodic checks. Sell increased uptime and fewer work stoppages due to dead packs.

Same-Day Turnaround for Tool Rental

If you run or partner with a rental shop carrying PWR CORE 20 tools, use dual-port chargers in intake areas so every returned battery immediately begins charging. The fast-charge mode gets 2.0Ah packs to ~25% quickly for test runs and immediate re-rental, while the second port completes full cycles, boosting fleet utilization.

Event/Makerspace Charging Bar

Set up a portable ‘charging bar’ for workshops, makerspaces, or community build days that use PWR CORE 20 tools. Offer quick top-offs with PWR JUMP and manage battery queues so participants aren’t waiting on power. Monetize with event fees, sponsorships, or rentals of the station itself.

On-Site Shop Fit-Outs

Package and install complete charging solutions for home garages and small businesses that rely on PWR CORE 20 tools: dual-port chargers, labeled battery bins, ventilated lockers, and signage explaining LED states and rotation best practices. Charge for design, installation, and training, then upsell maintenance visits.

Creative

Wall-Mounted Dual-Port Charging Dock

Build a French-cleat wall panel with a cradle shelf sized for the PWR CORE 20 Dual Port Auto PWR JUMP Charger plus labeled cubbies for “charged” and “empty” batteries. Add cable clips for tidy cord routing and a small acrylic window or open front so the LED indicators remain visible. The setup keeps two packs charging at once, and the UL-certified charger sits securely while still ventilated.

Mobile Charge Caddy

Create a compact, padded carry caddy that fits the dual-port charger, an extension cord, and 4–6 PWR CORE 20 batteries. Include airflow cutouts and a strap so you can roll into any room and plug in. The LED indicators face up for quick checks, and the fast-charge PWR JUMP mode lets you top a 2.0Ah pack to ~25% in about 5 minutes while you swap tools.

Ventilated Charging Locker with LED Sight Window

Build a small cabinet with louvered sides for ventilation and a clear front panel aligned to the charger’s LED indicators. Inside, add two shelves for extra batteries and a rear grommet for the power cord. The locker keeps dust off the charger, lets you see each bay’s status at a glance, and organizes a whole PWR CORE 20 charging zone.

Battery Rotation Station + Timer

Set up a benchtop station with the dual-port charger, a simple 5-minute sand timer, and labeled magnets or tags for each battery. When a pack hits empty, start the timer and drop it on the PWR JUMP bay; by the time the sand runs out, that 2.0Ah pack is roughly 25% and ready for light tasks while another charges on the second port. This turns the charger into a workflow tool to keep tools moving.

Jobsite Power Pit-Stop

Build a rugged plywood ‘pit-stop’ box with a hinged lid that holds the charger at an angle for easy LED viewing, plus compartments for bits, blades, and two spare PWR CORE 20 packs. Park it near your cutting station so you can continuously cycle two batteries—one fast-topping on PWR JUMP, one charging normally—minimizing downtime between cuts.