Features

- Time Saver: Solderless,crimpless, all you need is just a heat gun to finish the joint, much faster and easier than the old way

- Fit for Confined and Narrow Spaces: Can be bent after connection and no need to crimp or solder in the confined area, just control the temperature via a heat gun

- Waterproof and Seal Performance: There is two hot melt waterproof adhesive rings in each butt connector, which help it hold up better to moisture

- High Temperature Proof in A Short Time: Use exclusive material in the butt connectors to avoid shrink tubing melting before solder ring

- IATF16949:2016 Listed: The Kuject solder seal connectors meet the newest standard of International Automotive Task Force, which is the most standardized way for you to repair or modify your car

Specifications

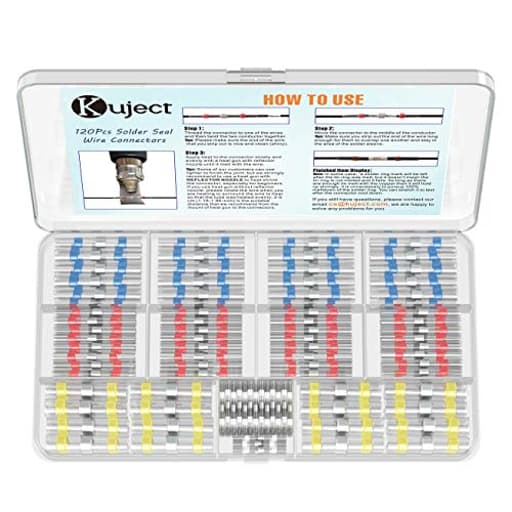

| Color | RED BLUE YELLOW WHITE |

| Size | 120PCS |

| Unit Count | 120 |

Related Tools

Heat-shrink solder-seal butt connectors for joining electrical wires without manual soldering or crimping; a heat gun is used to activate the internal solder ring and shrink the tubing. Each connector includes dual hot-melt adhesive rings for moisture sealing, is made from heat-resistant material to prevent premature shrinkage, and meets IATF16949:2016 automotive quality standards.

Kuject Heat Shrink Solder Seal Wire Connectors Kit 120PCS, Waterproof Butt Connector Heat Shrink Electrical Terminals, Insulated Solderless Wiring Splice Connectors for Marine Automotive Boat Truck Review

A field-tested, heat-and-go solution for clean, sealed splices

I put the Kuject connectors to work across a few everyday tasks: repairing a headlight pigtail on a truck, renewing a couple of corroded trailer light runs, and wiring a bilge pump on an older skiff. In each case, the goal was the same—make a reliable, weather-resistant butt splice without dragging out a soldering iron and crimpers. These heat-shrink solder-seal connectors did exactly that: slide, heat, inspect, done.

What you get and how they’re built

The kit is a 120-piece assortment spanning the common color-coded sizes (white, red, blue, yellow) for typical automotive and marine wire gauges. Each connector has:

- A low-temp solder ring centered inside the tube

- Dual hot-melt adhesive rings at both ends for sealing

- Heat-shrink tubing that’s transparent enough to see the joint as it forms

The tubing itself holds up to concentrated heat without collapsing prematurely, which matters. On cheaper connectors, the tube shrinks too soon and you never get a proper solder flow—the Kuject set resisted that tendency and gave me a wider heat window to get the solder ring to wet out.

The manufacturer touts IATF16949:2016 alignment, and while that’s a quality management standard rather than a performance spec, it does suggest a baseline of process control that shows up in consistent sizing, clean solder rings, and uniform shrink.

Using them: method and small but important details

The process is straightforward, but technique matters if you want repeatable results.

- Strip and prep: Match the connector size to your wire gauge. Strip each wire just enough to allow the copper to overlap beneath the solder ring. If the copper looks oxidized, give it a quick scrape or a dip in contact cleaner.

- Fit: Slide the connector over one wire, twist the conductors together with a modest overlap, then center the solder ring over the joint.

- Heat: I got the most consistent results with a small heat gun using a medium setting. Start at the center. Keep the nozzle moving and rotate the connector so the solder ring softens evenly. Once you see the solder turn glossy and wick into the strands (you’ll see it pull down into the copper), move the heat to the adhesive rings to finish the seal.

- Avoid blowouts: Don’t shrink the ends first; that traps air and can force the solder out of the sides. Start in the middle, then work toward the ends.

- Optional flux: If you’re working with slightly oxidized wire, a tiny dab of no-clean flux on the conductors speeds wetting and reduces the chance of a cold joint.

A lighter will work in a pinch, but it’s easy to scorch the tube or burn the adhesive. A heat gun gives you control and cleaner results.

Performance in real jobs

- Truck headlight pigtail: This is a classic “awkward reach” repair near other plastics you don’t want to melt. I appreciated not having to crimp in a tight space or balance a soldering iron near the fascia. The joint set quickly, the adhesive flowed out to the jacket edges, and the final splice was slim enough to fit the factory loom. No intermittent flicker after repeated on/off and a few days of driving.

- Trailer lights: The existing splices had greened up from road spray. After trimming back to bright copper, the connectors created a secure, watertight seal. I dunked the repaired section briefly and checked continuity after—still solid, and no visible moisture intrusion past the adhesive rings.

- Bilge pump wiring: Marine splices live in humidity and occasional splashes. Here the dual adhesive rings shine. After a week of on-water use, the joint remained clear, tight, and free of any milky haze that sometimes shows up when moisture creeps in.

Pull strength felt comparable to a good crimp: I could tug firmly without the joint slipping, and when I overdid it on a sacrificial test piece, the wire strands failed before the splice did. Electrically, I didn’t see any practical voltage drop across the joint on 12V systems beyond the tolerance of a handheld meter.

Where the kit shines

- Fast, tidy repairs: No separate crimp sleeves, no iron, no solder cleanup. The translucency lets you confirm the solder has actually wicked into both wire ends.

- Confined spaces: It’s simpler to heat from the outside than to angle a tool to crimp or solder at awkward angles.

- Weather resistance: Those dual adhesive rings do their job. For applications exposed to splash and road grime—trailers, motorcycles, engine bays away from exhaust—these are a real upgrade over plain crimps with heat shrink.

- Consistency: Across the handful I used from each size, the solder melted and adhesive flowed predictably. That’s not always a given with budget kits.

What could be better

- Solder flow on marginal wire: On older, slightly oxidized copper, the solder can be reluctant to wet. A touch of flux fixes it, but it’s another step to remember.

- Bulk of the finished joint: While slim for what they are, these are still thicker than a bare solder-and-standard-shrink splice. In very tight harness bundles, the extra diameter can add up.

- Vibration and strain: Like any butt splice, if you don’t provide strain relief, flex right at the joint can be a failure point over time. In high-vibration zones (handlebars, near engine mounts), I add a second length of adhesive-lined heat shrink overlapping the splice and anchor the wire to a loom or bracket.

- Rework: Once set, they’re not forgiving. If you mis-cut strip lengths or misroute a wire, you’ll be cutting the splice out and starting over.

Tips for reliable results

- Wire prep is half the battle. Bright copper and proper overlap make the solder wick quickly and fully.

- Size matters. Don’t try to stuff a large-gauge pair into a smaller tube; if you’re between sizes, step up, not down.

- Control the heat. Center first for solder flow, then ends to seal. Rotate the joint to heat evenly.

- Strain relief. Add an extra sleeve of heat shrink over the finished joint or secure the wire to a nearby harness to minimize flex right at the splice.

- Keep a few spares in your field kit. They’re ideal for roadside or dockside fixes where an iron isn’t practical.

Durability and environments

These connectors hold up well in damp, dirty conditions. I wouldn’t run them inches from exhaust manifolds or other sustained high-heat zones; the tubing is heat-resistant during installation but it’s not designed for constant high-temperature exposure. For submerged, long-term underwater runs, I still prefer a gel-filled or potting approach. For anything above the waterline or exposed to spray, these have been excellent.

Value

As an all-in-one solution, the Kuject kit hits a friendly price-per-splice and removes the need for separate crimpers, solder, and sleeves in many situations. The mixed sizes cover most light- to medium-gauge wiring I encounter on vehicles, trailers, and small boats. The kit format is also convenient: grab the right color, get it done, move on.

The bottom line

The Kuject connectors have earned a spot in my electrical kit because they reduce setup, simplify awkward repairs, and produce tidy, sealed splices that stand up to weather and vibration when properly strain-relieved. They’re not a silver bullet for every environment or wire condition, and—like any connector—they reward good prep and correct technique. But for most automotive, marine, and general DIY electrical jobs, they strike a very practical balance between speed and reliability.

Recommendation: I recommend this kit for anyone who needs fast, consistent, and weather-resistant butt splices without hauling around a full soldering setup. Use a heat gun, prep your wires, add strain relief where it makes sense, and these will deliver clean, dependable connections across a wide range of everyday wiring tasks.

Project Ideas

Business

Mobile Marine/Auto Waterproof Wiring Repair Service

Offer an on-site repair service for boats, trucks, and cars that specializes in quick, reliable waterproof splices using solder-seal connectors. Emphasize speed (no soldering/crimping), durability (heat-activated adhesive), and compliance (IATF16949-level quality). Market to marinas, truck fleets, and roadside assistance networks.

Prebuilt Sealed Wiring Harness Kits for DIYers

Create and sell plug-and-play wiring harness kits for popular upgrades—LED light bars, trailer wiring, off-grid solar, and EV bike conversions—using the solder-seal connectors for all splices. Include color-coded connectors, labeled leads, and assembly instructions. Sell through Etsy, Amazon, or specialty auto/marine stores as premium, weatherproof kits.

Hands-on Workshops & Certification Classes

Run short courses teaching safe, efficient solderless splicing, waterproofing techniques, and best practices for confined-space wiring. Use the connector kit as the course material. Offer a paid certification for marine and RV enthusiasts, electricians upgrading to sealed splices, or maker-space memberships—good recurring revenue and product sales.

Retrofit Package for Classic Car Owners

Offer a retrofitting service targeting classic/vintage car owners to replace brittle cloth or corroded original wiring with sealed, modern splices. Package includes inspection, harness replacement using IATF16949-grade connectors, and a service warranty. Market through classic car clubs, restoration shops, and online forums.

Subscription Repair Kit for Fleet Maintenance

Sell subscription boxes to fleet operators (marine fleets, delivery trucks, e-bikes) containing a curated selection of color-coded solder-seal connectors, a compact heat gun, wire prep tools, and quick-reference repair guides. Add volume discounts and optional remote troubleshooting support to reduce downtime and build long-term B2B relationships.

Creative

Waterproof LED Necklace/Bracelet

Build wearable LED jewelry using tiny LED strips or prewired LED modules and the heat-shrink solder-seal connectors to join wires. The waterproof adhesive rings protect the joints from sweat and rain, and the color-coded tubing becomes a decorative element. Use a low-temp heat gun to activate the solder ring and shrink the tubing for clean, flexible, and durable wearable circuits.

Driftwood or Bottle Lamp with Sealed LED Strips

Create a rustic lamp using driftwood or a glass bottle illuminated by LED strips. Use the solder-seal butt connectors to join strip leads and make right-angle connections inside tight cavities where crimping or soldering would be difficult. The waterproof seals protect the electronics from humidity, and the connectors' neat finish simplifies assembly for gifts or craft-fair pieces.

Upcycled Bicycle Taillight or Vintage Headlight Rewiring

Rewire old bicycle or vintage motorcycle lights with modern LEDs using the heat-shrink connectors to splice into existing harnesses. The IATF16949-grade connectors give a professional, reliable result without needing a soldering iron, and the heat-activated adhesive makes the joints vibration-resistant—perfect for moving craft projects and demonstrations.

Cable-Jewelry and Industrial Beads

Turn the colored butt connectors into industrial-style beads for bracelets, keychains, or mixed-media art. Join small segments of stranded wire inside the connectors, seal with a heat gun, and use the finished joins as decorative spacers that also hide concealed wiring for illuminated jewelry or pendant projects.

Scale Model/Electronics Diorama Wiring

When adding lighting to scale models, dioramas, or RC builds, use these solder-seal connectors to make compact, waterproof splices in confined model cavities. The small footprint and ability to bend after connection make routing wires easy; the sealed joints mean models can be handled or displayed in humid conditions without failing.