Features

- Specially designed for attaching composite and cellular PVC materials

- White color provides an ideal finish

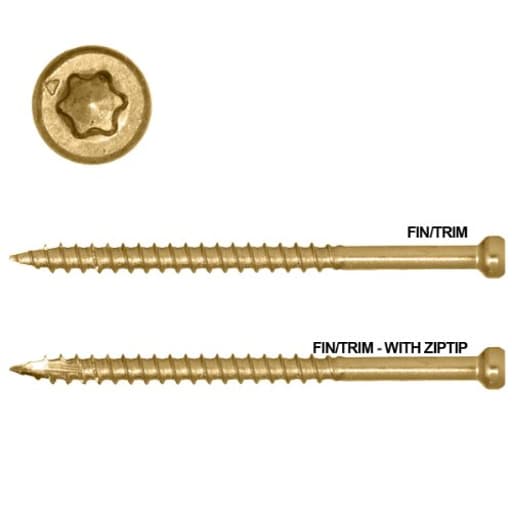

- Underhead reverse thread reduces or eliminates mushrooming

- For interior/exterior use

Specifications

| Color | White |

| Size | No Size |

| Unit Count | 505 |

#8 x 2-1/2-inch exterior trim screws in white, sold in a 505-count pack, designed for attaching composite and cellular PVC trim. They feature an underhead reverse thread to reduce or eliminate mushrooming, are suitable for interior and exterior use, and provide a white finish for a clean appearance.

GRK 16630#8 x 2-1/2" RT Composite Exterior Trim Screws - White 505 Count Review

I reached for these GRK trim screws on a recent exterior project where I was fastening cellular PVC and composite trim around windows and fascia. I wanted a clean, fastener-light look without the headaches that typically come with screwing into plastic-based materials. These fit the bill: a #8 x 2-1/2 size that grabs firmly, a white head that blends into most trim stock, and a design specifically meant to tame the “mushrooming” effect that plagues PVC and composite installs.

Design that addresses composite and PVC quirks

The standout feature is the reverse thread under the head. Traditional screws tend to compress PVC as the head seats, pushing up a halo of material around the drive recess. That means extra sanding, more filler, and longer finish work. The underhead reverse thread here actively pulls material down as the screw seats, reducing that raised ring. In practice, that translated into noticeably cleaner holes with far less bulging than I see with standard trim or deck screws.

The small, white head is another practical win. On white trim, many of my fasteners essentially disappeared once set flush, and the ones that did need filling required very little filler. If you’re used to bigger heads leaving large divots to patch, this is a welcome change. It’s also a durable finish: after installation and rain cycles, I had no flaking or discoloration.

Driving performance and holding power

I drove these into everything from 3/4-inch PVC trim to composite fascia backed by framing. The screws bite quickly and advance predictably, and I didn’t struggle with wobble or cam-out using an appropriate driver bit and steady pressure. Threads engage like you’d expect from a quality construction screw—no screechy, chattering drive and no tendency to spin out in PVC once the threads catch.

At 2-1/2 inches long, they’re a versatile “one-box-for-many-tasks” option for trim. That length is ideal for fastening typical 3/4-inch trim into framing or solid substrate, and it gives you enough thread engagement to pull warped pieces flat without overdriving. I had reliable clamping force even on slightly bowed PVC boards, which helped keep reveals tight.

Finish quality: better than typical, with one caveat

The underhead reverse thread reduces mushrooming a lot, but it doesn’t eliminate one specific nuisance: the occasional “pigtail” or thin sliver that forms as the head cuts in—particularly in cellular PVC. It’s the size of a small fingernail clipping and tends to stay attached at one end. In wood and wood composites, it usually sands off in a swipe or two. In PVC, I get the cleanest result by snipping it with a sharp utility knife rather than pulling it, which can tear the surrounding surface.

That small caveat aside, the overall finish is excellent. Most screws sat flush with a crisp perimeter; holes were consistently small; and with a quick swipe of exterior-grade filler where needed, I could prime almost immediately. If you’re chasing a high-end painted finish on trim, these help you get there faster.

Exterior-ready and appropriate for most conditions

These screws are rated for interior and exterior use, and in my testing they’ve held up well to weather. On a project with direct exposure to rain and sun, I haven’t seen rust streaking or head corrosion. For typical residential exteriors, that’s what I’d expect. If you work in highly corrosive environments—coastal salt air or constantly wet assemblies—stainless fasteners are still my go-to. But for most trim installs, these strike the right balance of durability and cost.

Pack size and jobsite value

The 505-count box is a practical quantity. It’s enough to handle a whole-house trim package without juggling multiple boxes or rationing screws across stages. The uniformity was excellent; I didn’t hit malformed threads or inconsistent heads in the batch I used, and every screw took a driver cleanly. That quality control matters—one out-of-spec head can slow down a workflow more than you’d think.

Tips for the cleanest results

Based on how these perform, a few practices maximize the finish quality, especially in PVC:

- Pre-chamfer when it matters. A quick pass with a countersink or a light chamfer on the surface prevents the pigtail and gives the head a crisp, flush landing. It’s an extra step, but for highly visible areas it makes the finish nearly flawless.

- Drive with a steady, controlled finish. Run the screw in fast, then slow down for the last turn. The final quarter-turn is where pigtails form; easing into the seat reduces them.

- Stop at flush. These heads are small; there’s no need to bury them deep. Overdriving creates more cleanup than it’s worth.

- Consider pilot holes in cold weather. PVC gets more brittle in the cold and can behave unpredictably with any screw. A small pilot keeps the surface pristine.

- Trim, don’t pull, the pigtail. In PVC, a clean knife cut is faster and safer than trying to tug it off.

Where they shine—and where they’re less ideal

These are purpose-built for composite and cellular PVC trim, and that’s where they beat generic deck or construction screws. The underhead reverse thread actually does what it claims—reduces mushrooming—and the white finish saves time on finish work. They’re equally at home indoors (think white-painted interior trim where you still want screw holding power) and outdoors, especially on porch wraps, frieze boards, and window trims that need a fastener you can confidently paint over.

A couple of limitations are worth noting:

- Color is fixed. If your trim isn’t white, you’ll either be filling and painting, or you’ll want a different head color for exposed fasteners.

- For extreme corrosion environments, choose stainless. These are robust for general exterior use, but stainless remains the safer bet near salt, pools with aggressive chemistry, or constantly damp assemblies.

Bottom line

As a fastener specifically tuned for composite and PVC trim, these GRK trim screws deliver. The underhead reverse thread meaningfully cuts down on mushrooming, the #8 x 2-1/2 format covers the majority of trim fastening scenarios, and the white head helps your work disappear once it’s painted. I appreciate how little fuss they create: they drive predictably, hold tight, and leave behind small, tidy holes that are quick to finish.

They aren’t magic; you’ll still occasionally see a thin pigtail in PVC as the head seats. But with a few simple techniques—pre-chamfering, easing into the final turns, trimming any sliver rather than pulling it—you can get near-perfect results.

Recommendation: I recommend these for anyone installing composite or cellular PVC trim who prioritizes a clean, efficient finish. They’re purpose-built for the material, reduce post-install cleanup, and come in a generous 505-count pack that’s well-suited to real jobsite demands. If you need color options beyond white or you work in highly corrosive environments, look at other variants or stainless alternatives. For most exterior trim work, though, these have become the screws I reach for first.

Project Ideas

Business

DIY Project Kit Seller

Assemble and sell pre-cut composite trim project kits (planter boxes, shelves, lattice panels) that include the correct quantity of white trim screws, instructions, and finishing tips. The 505-count pack lets you kit multiple projects per box—market to homeowners who want durable, low-maintenance outdoor upgrades on Etsy or Shopify.

Specialized Trim Installation Service

Offer a niche contracting service replacing rotted wood with composite/ cellular PVC trim. Position your service around using the right fasteners (white, exterior-rated, reverse-thread underhead) so customers get clean-looking, long-lasting installs. Charge premium rates for detail work on soffits, fascia, and porch shiplap.

Hands-on Workshops & Pop-up Classes

Run local workshops teaching simple composite projects (planters, small screening panels, shelves). Provide attendees with a small packet of the white composite screws and hands-on guidance about avoiding mushrooming and proper fastening techniques. Use workshops to upsell project kits and build an email list.

Seasonal Maintenance Subscription

Sell a yearly ‘exterior trim maintenance’ subscription that sends customers a small supply of white composite screws, touch-up supplies, and a simple inspection/checklist each season. Target homeowners with composite trim who prefer preventive maintenance over costly repairs—packaging can include guidance on when to replace fasteners and how to avoid surface defects.

Contractor Bulk Bundles & Co-branding

Create tailored bulk bundles for local contractors—pre-counted packs sized for typical jobs with specification notes on why underhead reverse-thread screws are preferred for composite/PVC. Offer co-branding (stickers, cards) and volume pricing to get into contractor trucks and trade-stores as the go-to composite trim fastener.

Creative

Weatherproof Planter Boxes

Build raised planter boxes from composite or cellular PVC boards that won't rot. The white screws blend with lighter finishes for a clean look; the underhead reverse thread prevents mushrooming on thin board edges so the lid and trim stay flush. With a 505-count pack you can make several medium-sized boxes for porch and patio.

Porch Shiplap Accent

Cover a porch ceiling or an exterior accent wall with composite shiplap to get a polished, low-maintenance finish. Use the white trim screws for an unobtrusive fastener line; the reverse thread reduces surface defects on the trim pieces so painting or caulking is easier. Ideal for interior/exterior transitions like breezeways.

Privacy Lattice Screen

Construct freestanding decorative privacy screens or trellis panels from composite slats. The screws are designed for composite/PVC attachments, giving a strong, weatherproof hold for outdoor use. The high unit count lets you create several panels or a multi-section screen system for balconies and patios.

Outdoor Shower / Spa Wall

Clad an outdoor shower or small spa enclosure with cellular PVC for a waterproof, easy-to-clean surface. The exterior-rated white screws maintain a tidy appearance and the underhead reverse thread minimizes mushrooming on the thin trim pieces used around niches and joints—great where aesthetics meet moisture resistance.

Floating Bathroom Shelves

Make moisture-resistant floating shelves using composite boards for bathrooms or pool houses. White screws keep the visible fasteners discreet against light-colored boards; because these screws are made specifically for composite materials, they reduce splitting and give secure anchorage in hidden brackets or face-mounted cleats.