Features

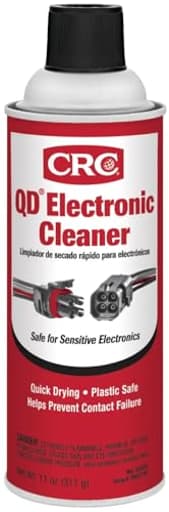

- QD ELECTRONICS CLEANER: A precise cleaner made from petroleum distillate and alcohol that is fast evaporating and leaves no residue.

- FORMULA: With quick-drying, plastic safe, residue-free features, this cleaner is ideal for even the most sensitive electronics and will help to prevent contact failure.

- APPLICATIONS: QD Electronic Cleaner is ideal for use on computer components, circuit breakers, circuits, coin mechanisms, contacts, flux removal, sockets, lighting, plastics, nylon, plugs, relay switches, PVC, and more!

- PRODUCT SPECIFICATIONS: QD Electronic Cleaner is available in a 11 wt. oz. aerosol can.

- CRC INDUSTRIES: A market leader that offers impeccably designed chemical solutions to maintain, protect and repair different marine, heavy-duty motor vehicles, industrial-grade engines, household tools, and electrical equipment.

Specifications

| Color | Red |

| Size | 11 Ounce (Pack of 1) |

| Unit Count | 1 |

Related Tools

An 11 oz aerosol electronic cleaner formulated from petroleum distillate and alcohol for fast evaporation and residue-free cleaning. It is quick-drying and plastic-safe for use on sensitive electronics such as circuit boards, connectors, relays, coin mechanisms, sockets, and for flux removal to help reduce contact failure.

CRC 05103 QD Electronic Cleaner -11 Wt Oz Review

Why I Keep This Cleaner Within Arm’s Reach

I keep a can of CRC’s QD Electronic Cleaner on my bench because it solves a common problem quickly: removing grime, oxidation, and leftover flux from sensitive electronics without leaving a residue. It’s an 11 oz aerosol, formulated with petroleum distillates and alcohol, and it’s become my default choice for fast, plastic-safe cleaning where I don’t want lubricants or films left behind.

Over the past few months I’ve used it on a scratchy volume pot in an older stereo receiver, a set of oxidized motorcycle handlebar switches, a sticky relay on a control board, and the aftermath of a small soldering session (flux removal on a PCB). In each case, the cleaner did what I needed—cut through contaminants and evaporate quickly—without introducing new issues.

Performance and Cleaning Speed

The “quick-dry” claim isn’t marketing fluff. The spray flashes off very quickly, which is exactly what I want when cleaning energized assemblies I’ve powered down only briefly, or when I need to reassemble something and test it without waiting around. That speed, combined with a genuinely residue-free finish, means I can clean a contact, give it a short burst of compressed air, and be back to troubleshooting in minutes.

On lightly oxidized contacts, the cleaner alone often restores performance. The stereo pot stopped crackling after two short applications while I rotated the shaft through its travel between bursts. For heavier oxidation or stubborn deposits, I’ve had better results pairing the cleaner with a fiberglass pen or very fine abrasive, then flushing thoroughly to carry away loosened debris. This isn’t a magic eraser for badly pitted contacts, but as a flushing solvent for electronics, it’s very effective.

Flux removal is another strong suit. It dissolves and lifts common rosin residues easily and leaves boards looking pristine without the haze some slower solvents leave behind. Because it evaporates fast, you don’t get pooling under components as long as you’re sensible with the amount you apply.

Control and Precision

The straw makes a difference. Being able to direct a narrow stream right into slider tracks, relay housings, or between closely spaced components keeps overspray to a minimum and reduces waste. I find short, controlled bursts at a slight angle help carry dissolved grime out rather than forcing it deeper in. After spraying, I usually chase with compressed air to blow contaminants off the workpiece and out of crevices.

One minor gripe: with one of my cans, the straw/nozzle interface felt a little loose, and I noticed some fluid collecting at the top of the can during long sprays. Keeping the can upright and using shorter trigger pulls largely eliminated it, but it’s worth watching so you don’t waste product. Wiping the nozzle periodically also helps maintain a clean jet.

Materials Compatibility

The cleaner is advertised as plastic-safe, and in my use it has been gentle on the usual suspects—nylon, PVC, and common connector housings—without whitening or stress-cracking. I still recommend a quick spot test on unknown plastics or older brittle parts, especially clear polycarbonate windows or lenses that can be more sensitive to solvents.

Importantly, this cleaner leaves no protective film. That’s a positive for most electronics work, but if you’re cleaning a potentiometer or fader that relies on a lubricated track, plan to follow up with a product designed to re-lubricate controls. My workflow is: flush with this cleaner, exercise the control, let it dry, then apply a purpose-made fader lube sparingly.

Where It Shines (and Where It Doesn’t)

Shines:

- Contact cleaning in switches, relays, and connectors where you want zero residue

- Pots and sliders on vintage audio gear to remove contamination quickly

- PCB cleanup after soldering, including spot flux removal

- Degreasing small electrical components before diagnostics or repair

- Cleaning adhesive smears or tape residue from housings without leaving a film

Less ideal:

- Heavy, baked-on corrosion where mechanical work is unavoidable

- Situations requiring a protective or lubricating film (use a companion product afterward)

- Cleaning tasks near ignition sources—like most solvents, this is flammable, so power down and ventilate

Technique Tips for Best Results

- Power down and unplug. Even with a “dry” cleaner, I don’t spray energized electronics. It’s safer, and you’ll do a better job when you can manipulate parts freely.

- Use short bursts and let gravity help. Angle your spray so contaminants flow out and away from the component.

- Combine with mechanical action for oxidation. A fiberglass brush, contact burnisher, or even a wooden toothpick can dislodge oxides the solvent loosens.

- Follow with air. A quick blast of compressed air removes residue and speeds drying in tight spaces.

- Relube when appropriate. After cleaning pots or sliders, apply a suitable lubricant if the component design calls for it.

- Spot test plastics. It’s plastic-safe in my experience, but a quick test on an inconspicuous area is smart on unknown materials.

Build, Can Size, and Value

The 11 oz can is a practical size for a bench—large enough that you don’t feel stingy, small enough to maneuver in tight spots. The actuator has a positive feel, and the included straw provides good reach. The solvent blend has the familiar “shop” smell of petroleum distillates with alcohol; adequate ventilation keeps it from lingering.

From a value standpoint, I like that I can use it liberally during a diagnostic session without worrying about residue cleanup afterward. Because it doesn’t leave a film, there’s less rework. I’ve also found that cleaning first often saves parts that would otherwise be replaced—oxidized connectors and switch gear are frequent culprits—so the can pays for itself quickly.

How It Stacks Up Against Alternatives

Compared with contact cleaners that include additives or conditioners, this product’s strength is its neutrality: fast-evaporating and residue-free. That makes it better for general electronics cleaning and flux removal, and for components where you do not want any post-cleaning film.

If you need both cleaning and lubrication in one step—for example, treating noisy faders in a mixer—there are specialty products that combine solvents with conditioners. I prefer the two-step approach: clean thoroughly with a residue-free solvent, then apply the right lube in a controlled amount. It’s more precise and avoids accumulating films where you don’t want them.

There are also heavier-duty degreasers with slower evaporation for mechanical parts; those can be overkill on sensitive electronics and may not be plastic-safe. This cleaner hits the “electronics-safe and fast” sweet spot.

Safety Notes

- Use in a well-ventilated area and keep away from open flames or hot surfaces. The solvent base is flammable.

- Wear eye protection; debris can eject as you flush components.

- Avoid prolonged skin contact, and wash up after use.

- Dispose of used swabs and wipes in accordance with local regulations; they’ll be solvent-laden.

The Bottom Line

CRC’s QD Electronic Cleaner has earned a permanent spot in my kit for one simple reason: it cleans sensitive electronics quickly and leaves nothing behind. It’s plastic-safe, it evaporates fast, and it’s versatile enough to handle everything from vintage audio maintenance to PCB flux cleanup and connector rehab.

I recommend it. If you need a reliable, residue-free cleaner for electronics work—especially for diagnosing intermittent faults caused by contamination—this is a solid, cost-effective choice. Pair it with the right mechanical tools and, when needed, a follow-up lubricant, and you’ll restore more components than you replace.

Project Ideas

Business

Vending & Arcade Maintenance Service

Offer scheduled cleaning and preventative maintenance for vending machines, coin-op arcades and laundromats—key customers who suffer revenue loss from dirty coin mechanisms and sticky switches. Use the QD cleaner to rapidly restore coin acceptors, button stacks and connector contacts onsite, bundled with simple diagnostics and a small parts replacement service. Position as a subscription service (monthly/quarterly) to create recurring revenue.

Refurb & Resell Electronics

Start a micro-business buying non-working vintage radios, mixers, synths or game consoles, using the cleaner to remove corrosion and flux as part of a refurbishment workflow. Cleaned, tested and cosmetically refreshed units can command higher resale prices on marketplaces like eBay or Reverb. Document the restoration process with before/after photos and offer limited warranties to increase buyer trust.

Preventive Maintenance Contracts for Small Industry

Sell preventive maintenance packages to small manufacturers, labs, and server rooms focused on reducing contact failure and downtime. Use the cleaner for scheduled PCB, relay, connector and breaker upkeep, combined with inspection reporting and replacement recommendations. Offer tiered contracts (basic cleaning, advanced diagnostics, emergency response) to capture different client budgets.

Kits + Video Tutorials (DIY Electronics Care)

Create and sell starter kits that pair the QD electronic cleaner with anti-static mats, ESD-safe brushes, nozzle adapters and short how-to videos for hobbyists and technicians. Position kits on Etsy or Shopify and upsell digital courses on electronics maintenance and safe chemical handling. Videos increase trust and reduce customer support time.

On-site Audio Gear Service for Musicians/Venues

Offer a mobile service for bands and venues to clean and service pots, jacks, faders and patchbays, reducing noise and dropouts before shows. The cleaner is ideal for quick turnarounds between gigs because it dries fast and leaves no residue. Market to rehearsal spaces, small venues and local musicians with flexible scheduling and rapid-response packages.

Creative

Vintage Radio / Amp Restoration

Use the QD electronic cleaner to remove dust, grime and oxidized contacts from switches, tube sockets, and PCB traces as part of a full cosmetic and functional restoration. Combine cleaning with cap replacements, knob refurbishment and a fresh chassis polish to create a display-quality piece. Work in a well-ventilated area and mask delicate labels or painted surfaces; the cleaner’s fast-evaporating, residue-free formula speeds reassembly and testing.

Arcade / Pinball Refurb Project

Refurbish old coin mechanisms, push buttons, microswitches and connector pins on an arcade or pinball cabinet to bring responsiveness back to life. The aerosol spray reaches tight switch housings and connector cavities to displace contaminants and old flux, making it ideal before lubing mechanical parts or replacing plastics. Use it as part of a weekend makeover with new art, LEDs and playfield touch-ups.

Steampunk / Circuit Jewelry

Create wearable art from salvaged circuit boards and connector pieces that are cleaned to a safe, presentable finish with the QD cleaner. The residue-free formula lets you safely remove flux and grime before sealing or mounting pieces on chains, cufflinks or brooches. Pair with clear epoxy or glass cabochons for a polished, gallery-ready look.

RC & Model Precision Maintenance

Keep radios, ESCs, servos and motor commutators performing by using the cleaner to remove dust, oil and salt spray without leaving residue that could impair electronics. It’s great for season-start tune-ups on model airplanes, drones, cars and trains—spray connectors, bearings and gearboxes (then dry and re-lubricate appropriate mechanical parts). Always power down and remove batteries before cleaning.

Soldering / Maker Workshop Kit

Assemble a small workshop kit for electronics hobby nights that includes the QD cleaner for flux removal and contact prep. Demonstrate pre- and post-solder cleaning to students so boards look professional and have reliable connections. The quick-dry, plastic-safe properties make it suitable for classroom use when paired with gloves, eye protection and ventilation.

![Electronic Wipes Screen Cleaner Streak-Free [2 Pack x40] Computer Screen Wipes, TV Screen Cleaner Wipes, Monitor Wipes for Smart TV, Laptop, iPhone, ipad and more - [Microfiber Cloth + 80 Wipes]](https://images.toolstash.com/variants/hn76cf1qozvtks1da54ozbnmatmw/thumb.webp)