Features

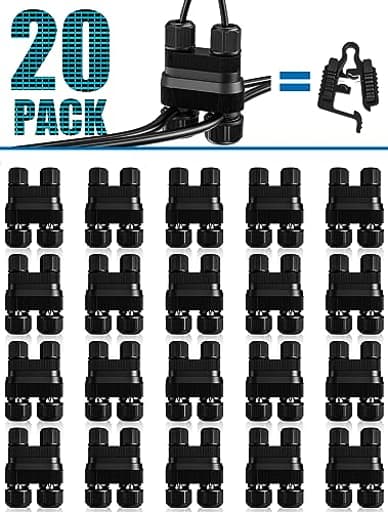

- 【Upgraded, Covering20 Lights】Upgraded SUNVIE fastlock2 low voltage landscape lighting connector. Only 1 connector is required per connection. 20 connectors cover 20 lights, making connection easier. PATENT NO. : US D935,409 S

- 【Easy to Install】No crimping, No cutting, No splicing. Our fastlock2 low voltage wire connector with three-piece screwing design, easily connect your all kinds of landscape lights to the low voltage cable in few minutes.

- 【Ultra Strong Material】SUNVIE fastlock2 landscape lighting connectors are made of extremely sturdy nylon plastic + fiberglass mixture and CNC machined nickel- plated brass pin to ensure corrosion resistance and electrical conductivity for outdoor use.

- 【Wide Application】Perfectly match 12/14/16/18 AWG low voltage landscape lighting wire. Fit for landscape lights, path lights, in-gound lights, deck ligths, etc. with 16/18/20/22 gauge wire. Widely used in garden, pathway, driveway, yard, patio, lawn, walls, trees, flags etc.

- 【Lifetime Warranty】60-day money-back guarantee, 5-year replacement warranty and lifetime after-sales support guarantee. Feel free to contact our customer service team if you encounter any issue.

Specifications

| Energy Efficiency Class | efficient |

| Color | Brass |

| Unit Count | 20 |

Related Tools

Waterproof low-voltage wire connectors for outdoor landscape lighting that join fixture leads to 12–18 AWG supply cables. The three-piece screw-down design enables connections without crimping, cutting, or splicing; housings are molded nylon/fiberglass with nickel‑plated brass pins for corrosion resistance and conductivity. Pack of 20 connectors (one per light).

SUNVIE Fastlock2 Low Voltage Wire Connector Landscape Lighting Connectors Waterproof 12-18 Gauge Wire Connectors for Low Voltage Landscape Lights Outdoor Landscape Path Lights, 20 Pack Review

Why I switched to these connectors for low‑voltage lighting

After years of living with pierce-style “vampire” taps and gel-filled wire nuts on my landscape lighting, I finally tried the SUNVIE Fastlock2 connectors. The promise is simple: one connector per light, no cutting or splicing the main cable, and a waterproof, reusable connection. I installed them across a garden path and around a patio on a 14 AWG trunk with a mix of path and uplights. The short version: they made the job faster, cleaner, and so far more reliable than my usual methods—with a few important caveats worth understanding before you commit.

What they are

Fastlock2 connectors use a three-piece screw-down design to join a fixture’s two leads to a low-voltage supply cable (12–18 AWG). The housings are a rigid nylon/fiberglass blend, and the contact pins are nickel‑plated brass. Each connection uses a single compact unit rather than two separate splices, so one pack of 20 truly covers 20 fixtures. They’re intended for outdoor use in typical landscape lighting runs: path lights, spots, deck lights, and in‑ground fixtures.

Setup and installation

The workflow is straightforward once you’ve done a couple:

- Split the main supply cable’s two conductors enough to straddle the connector’s channels.

- Seat the trunk wire firmly into the body so the supply conductors sit flat in their respective tracks.

- Insert each fixture lead into its smaller side ports.

- Thread on the two large caps (for the trunk) and the small cap (for the fixture leads), then tighten by hand until you feel solid resistance.

A few practical tips from my install:

- Press the trunk wire fully into place before tightening. If it isn’t seated, the cap can misthread or “ride” the start of the threads.

- Go snug, not gorilla-tight. The housing is tough, but overtightening can damage the caps, especially with stiffer 12–14 AWG runs.

- For pre-tinned fixture leads, lightly twist to keep strands together and insert straight. These connectors like loose, stranded copper; tinned ends fit, but they need a bit more attention.

Compared to wire nuts or pierce-style taps, the time savings were real. I didn’t have to cut the trunk, pull insulation, or deal with separate weather boots. Each connection took me a couple of minutes once I got a rhythm.

Build quality and weather resistance

The body feels robust and the nickel‑plated pins are a smart choice for outdoor corrosion resistance. The trunk side, once tightened, forms a secure, water-resistant clamp around the insulation and conductors. The fixture-lead side is more exposed by design so it can accommodate a range of lead gauges (16–22 AWG); it’s splashproof, but if you expect standing water, saturated mulch, or submersion, you’ll want to add protection.

What worked well for me:

- A small dab of dielectric grease in the lead ports before tightening.

- Self-fusing silicone tape over the fixture-lead end in damp zones or where snow piles up.

- Mounting connections off the soil line—under a fence rail or clipped to a stake—whenever possible.

Used this way, I’m comfortable calling the assembly weather-ready for typical landscape conditions. If you need submersible or direct burial splices with full encapsulation, you’re better off with gel-filled heat-shrink connectors.

Electrical performance

Performance has been solid. Continuity is reliable, and voltage at the last fixtures in my run stayed consistent with what I expect on a 14 AWG loop at 12–15 volts. The nickel-plated contacts bite cleanly into copper without shredding strands. I didn’t observe flicker or intermittent behavior after the first week of temperature swings and irrigation cycles.

One underappreciated benefit: because you don’t cut the trunk, you avoid creating extra joints and potential drop points. If you’ve ever had to hunt through a line of buried splices to find a dimming issue, you’ll appreciate how these simplify fault isolation.

Compatibility and use cases

- Trunk cable: 12, 14, 16, or 18 AWG landscape cable fits. With 12 and 14 AWG, alignment matters—take your time threading the caps straight.

- Fixture leads: 16 to 22 AWG. Stranded copper is ideal; tinned leads work but require a firmer hand to seat fully.

- Fixture types: path lights, small spots, deck lights, in‑ground lights (for in‑ground, seal the lead side as noted).

They’re a nice match for mixed systems where different fixtures have different lead sizes, or for upgrades where you don’t want to rebuild the trunk.

How they compare

- Versus pierce-style “vampire” taps: Faster and generally more reliable. Those taps can loosen with seasonal expansion/contraction and are notorious for intermittent contact and corrosion. Fastlock2 grips more like a compression block.

- Versus gel-filled wire nuts/heat-shrink splices: Those are more watertight but require cutting the trunk and making two splices per light. Fastlock2 uses one connector and keeps the main cable intact, which saves time and reduces points of failure. If your environment is very wet or connections must be buried, gel-filled splices remain the gold standard.

Pain points and tradeoffs

- Threading on stiff runs: With 14 AWG trunk cable, the first quarter-turn is the danger zone. If the cap isn’t square, it can cross-thread. Starting gently and keeping axial pressure on the cap as you turn helps.

- Not truly sealed on the lead side: These are weather-resistant, not submersible. Add grease and tape if your connections sit in water-prone spots.

- Hand fatigue: Tightening twenty caps in a session left my fingers a bit sore. A rubber jar opener or light-grip pliers can help snug the last turn—just don’t overtighten.

- Bulk: Each connector adds some size to the line. It’s tidy compared with a pair of splices, but you’ll still notice it if your run is exposed on a deck.

None of these are deal-breakers; they’re more about learning the connector’s feel and planning for your environment.

Longevity and serviceability

One of the practical advantages is reusability. If you misplace a light or need to reroute, you can back the caps off, reposition the connector, and retighten without sacrificing hardware. That’s not true of heat-shrink or gel nuts. The materials choices suggest a long service life, and the nickel plating should stave off the usual outdoor corrosion that ruins cheap connectors. The warranty—a money-back window, multi-year replacement, and ongoing support—adds confidence if you’re equipping an entire property.

Best practices for a trouble-free install

- Pre-plan fixture spacing so you’re not wrestling connectors in tight shrub beds.

- Make clean, square cuts on fixture leads and keep copper strands bundled.

- Seat the trunk fully before tightening; apply steady axial pressure to the caps.

- Use dielectric grease in the lead ports; wrap with self-fusing tape in wet zones.

- Keep connections off the soil line where possible.

- After assembly, tug-test both fixture leads and the trunk. If anything moves, retighten.

- Label or map your connections—future you will thank you.

The bottom line

The Fastlock2 connectors earned a place in my lighting kit. They strike a smart balance between speed, reliability, and field serviceability. I can connect a fixture in minutes, keep the trunk intact, and have a neat, low-resistance joint without special tools. They’re not a cure-all—if your connections will live underwater, you need a fully sealed splice—but for most landscape lighting tasks around paths, beds, and decks, they make the job easier and cleaner than the old standbys.

Recommendation: I recommend these for homeowners and pros who want faster, cleaner low-voltage lighting installs without cutting the main cable. They’re especially worthwhile on long runs with many fixtures, where saving time per connection adds up and reusability matters. Just be mindful with 12–14 AWG trunks (start threads carefully, don’t overtighten), add dielectric grease on the lead side, and keep connections out of standing water. With those practices, the Fastlock2 strikes a very good balance of speed, durability, and performance.

Project Ideas

Business

Turnkey Backyard Lighting Installations

Offer a local installation service specializing in low‑voltage landscape lighting that emphasizes fast, clean connections using Fastlock2 connectors. Market the no‑crimp/no‑splice advantage for faster installs and easier future service calls; bundle a 20‑connector pack per job and offer extended maintenance plans backed by the connectors' warranty.

DIY Landscape Lighting Kits

Create retail kits for homeowners that include pre‑cut 12–18 AWG cable, fixtures, a 20‑pack of Fastlock2 connectors, step‑by‑step instructions and a how‑to video. Position kits by use case (path lights, deck lights, accent fixtures) so buyers get everything they need to install without special tools like crimpers or soldering irons.

Hands‑On Workshops and Online Courses

Run paid workshops or a subscription video series teaching landscape lighting design and installation. Use the Fastlock2 connectors in demos to show quick, tool‑light techniques. Sell connector packs and starter kits as class materials and offer affiliate links or bundle discounts for attendees.

Custom Illuminated Garden Art Studio

Design and sell custom garden art and signage with integrated low‑voltage lighting. Use Fastlock2 connectors to make pieces plug‑and‑play for customers—easy to install and service. Offer add‑ons like seasonal lighting swaps or modular expansion panels that connect on site with the same connectors.

Subscription Maintenance & Replacement Service

Provide a recurring service that inspects, cleans, and replaces worn landscape lighting components. Include connector checks and swap damaged Fastlock2 units as part of the plan; advertise the time saved by using screw‑down, no‑crimp connectors for quick field repairs. Offer different tiers (annual check, seasonal swap, emergency repair) and sell connector packs to DIY subscribers.

Creative

Modular Light Mosaic Panels

Build interlocking outdoor art panels made from small boards or acrylic sheets with embedded low‑voltage LED strips. Use the Fastlock2 connectors at each panel edge so panels can be snapped together or rearranged without soldering or splicing. Waterproof connectors and nickel‑plated pins make the mosaics safe for gardens and patios; a 20‑pack covers many panel junctions.

Floating Pond Lanterns

Create floating lanterns from sealed jars, recycled buoys, or 3D‑printed shells with low‑voltage LED modules. The Fastlock2 connectors let you make easily replaceable light modules (no crimping required) that plug into a single low‑voltage feed along the pond edge. Waterproof housings and corrosion‑resistant pins protect the connections near water.

Illuminated Trellis and Plant Support

Incorporate low‑voltage mini spotlights or string lights into a garden trellis or pergola to highlight climbing plants. Use the Fastlock2 connectors to attach fixture leads to the main feed cable quickly during assembly or seasonal reconfiguration. The screw‑down design and wide gauge compatibility (12–18 AWG) make adjustments fast and reliable outdoors.

Upcycled Bottle Path Lights

Turn glass bottles, old lantern housings or small planters into path lights using low‑voltage LED modules. Fastlock2 connectors let you connect each fixture to the supply cable without cutting or splicing, keeping the build reversible and maintenance‑friendly. The waterproof nylon/fiberglass housings are ideal for yard use.

Holiday & Event Light Sculptures

Construct seasonal wireframe sculptures (reindeer, stars, arches) wired with low‑voltage LEDs. Use the Fastlock2 connectors at modular joints so sculptures can be disassembled, stored, and reassembled quickly. The corrosion‑resistant brass pins and outdoor‑rated housings ensure last‑season‑to‑season durability.