Features

- Targeted Anti-Condensation Protection – Spray-on pipe insulation designed to stop sweating and dripping at the source. Ideal for use on hard-to-reach areas, fittings, valves, strainers, and flanged assemblies where traditional wrap insulation struggles. Prevents water damage, corrosion, and unsightly moisture stains in plumbing, HVAC, and refrigeration systems

- Durable, Water-Resistant & Paintable Finish – Dries to a tough, flexible coating that prevents cracking, peeling, and moisture over time. Overspray cleans up easily as a dry powder. Great for touch-ups or for sealing gaps around foam sleeves, wraps, and other insulation materials

- Multi-Surface Adhesion for Versatile Applications – Bonds tightly to copper, stainless steel, galvanized steel, PVC, brass, and even porcelain. Works on cold water pipes, refrigeration lines, condensers, toilet tanks, water heaters, and complex pipe geometries like joints and connection points

- High Coverage Efficiency – Less Waste, More Value – One can covers up to three coats on 4 feet of 2-inch pipe or 16 feet of ½-inch pipe (actual coverage varies with surface shape and texture). Enjoy professional-grade insulation performance without the hassle and bulk of traditional wrap products

- Safety & Compliance You Can Trust – Non-flammable when dry and safety-evaluated for non-food contact surfaces. Suitable for use in food processing plants, hospitals, institutional facilities, and mechanical rooms where both performance and safety standards matter

Specifications

| Color | White |

| Unit Count | 1 |

Spray-on pipe insulation for hard-to-reach areas, fittings, valves, and complex pipe geometries that stops condensation and dripping on plumbing, HVAC, and refrigeration lines. It bonds to copper, stainless steel, galvanized steel, PVC, brass and porcelain, dries to a flexible, water-resistant, paintable finish, and one can covers up to three coats on 4 ft of 2-inch pipe or 16 ft of ½-inch pipe; non-flammable when dry and evaluated for non-food-contact surfaces.

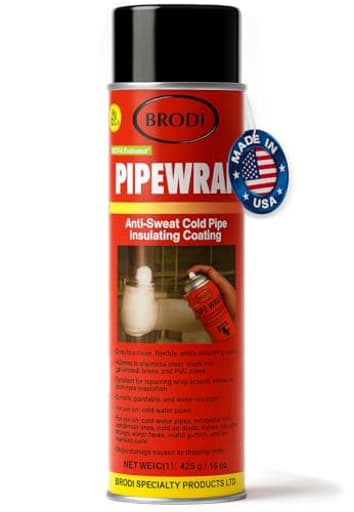

Brodi PipeWrap Pipe Insulation Spray Foam for Hard-to-Reach Areas, Fittings & Valves, Anti-Sweat Pipe Coating Spray, Stops Condensation Buildup & Prevents Dripping in Plumbing, HVAC & Refrigeration Review

Why I reached for a spray instead of another wrap

If you’ve ever tried to stop condensation on tight fittings, valves, or oddball bends, you know traditional foam sleeves or tape wraps can be a fight you rarely win neatly. I started testing the PipeWrap spray because I needed something that would actually get into those congested spots—service valves on an AC suction line, a cluster of 1/2-inch copper tees above a water heater, and a perpetually sweating cold line under a bathroom sink. I wasn’t expecting miracles; I just wanted dry floors and no more slow drips. That’s exactly the type of problem this spray is built to solve.

What it is (and what it isn’t)

PipeWrap spray is a spray-on, flexible insulating coating intended to stop sweating and dripping on cold plumbing, HVAC, and refrigeration lines. It adheres to copper, stainless, galvanized, PVC, brass, and even porcelain. It dries to a slightly textured, matte white finish that’s water-resistant and paintable. It’s excellent for targeted anti-condensation control on fittings, valves, strainers, and other shapes where wraps are bulky or leave gaps. It’s not a replacement for full-length pipe insulation where you need meaningful R-value for energy efficiency; think of it as a surgical tool for the trouble spots that cause the mess.

Where it shines

- Hard-to-reach geometry: The spray finds its way around stems, flanges, and couplings where sleeves can’t seat. I used it to bridge the seams where split foam sleeves meet elbows—no more exposed cold metal at the joints.

- Mixed materials: I tested it on copper and PVC, plus a porcelain toilet tank that had a recurring condensation ring in humid weather. Adhesion was solid across all three, provided the surfaces were cleaned and dry.

- Quick touch-ups: If you’ve ever had to carve and tape around a valve, this feels refreshing. Three light coats gave me a continuous skin without lumps or tape edges.

Application: prep and technique matter

Prep is the difference between a great result and one you’ll be scraping off. Here’s what worked consistently for me:

- Stop the sweating before you spray. If the pipe is already wet or clammy, the coating won’t bond well. I shut off the fixture or HVAC circuit temporarily, wiped everything dry, and, in muggy conditions, warmed the metal slightly with a hair dryer for a minute or two.

- Clean aggressively. Degrease with a mild cleaner or isopropyl alcohol, then dry. Dust and fingerprints reduce adhesion.

- Mask more than you think. The spray has a fluffy, dusty overspray that settles. I used painter’s tape, paper, and a cardboard shield behind the work to control it.

- Build in thin coats. I shook the can thoroughly, sprayed from about 8–12 inches, and used light passes. My rhythm was three coats, roughly 15–20 minutes apart, aiming for a uniform, 1–2 mm shell. Heavy coats tend to sag and don’t cure as evenly.

- Allow a full day before exposure to moisture. Touch-dry happens quickly, but for real moisture resistance, I had best results when I waited about 24 hours.

On a 1/2-inch copper run with tees and a shutoff valve, the third coat was the tipping point—after that, no dew formed even on humid days. On a frigid AC suction line, I needed a bit more thickness around the service valve body; an extra pass just on that area did the trick.

Coverage and build

The can’s stated coverage—up to three coats on 4 feet of 2-inch pipe or 16 feet of 1/2-inch—tracked pretty closely with my use. One can got me three coats over roughly 10–12 feet of 1/2-inch with a handful of fittings and a couple of heavier applications at valves. Coverage drops on complex shapes; plan accordingly. I’d rather lay down three lighter coats than two heavy ones for better control and fewer sags.

The finish: paintable, flexible, forgiving

Once cured, the coating forms a flexible, slightly spongy skin. It doesn’t crack when pipes flex a bit during thermal cycles, and it resists casual scuffs. I painted a section to match a wall with a standard latex topcoat—no primer needed for light colors. On a porcelain tank, the white finish looked intentional enough that I left it unpainted.

If you overspray onto nearby surfaces, it dries into a fine powder that wipes off or vacuums easily. That feature saved me a couple of nervous moments when I overreached near a condenser shroud.

Durability and adhesion

Over several weeks of humid weather, all treated points stayed dry and intact. Adhesion was best on clean, dry metal; the only time I saw flaking was when I tried to cheat the prep on a slightly damp copper elbow. I stripped it back with a nylon brush, cleaned properly, and re-applied—no issues after that.

On PVC and porcelain, I was expecting compromises, but the bond held up well after proper degreasing. I checked edges around a high-traffic utility sink line and didn’t see peeling.

Mess factor and control

This is where you need to respect the product. The spray pattern is wide and airy, which is great for coverage but will dust the surroundings. Wear gloves, eye protection, and mask off generously. I also recommend:

- Using a cardboard spray shield to cut down on airborne float.

- Clearing the area—don’t keep tools on a nearby shelf.

- Laying a drop cloth on the floor.

Cleanup was painless when I followed these steps. If you treat it like a precise adhesive spray, you’ll be frustrated; treat it like texture coat and you’ll be fine.

Safety notes

The coating is non-flammable when dry and is safety-evaluated for use on non-food-contact surfaces, which makes sense for mechanical rooms, hospitals, and institutional facilities where compliance matters. I still worked with standard ventilation and PPE because the atomized particles behave like a light dust. Check the can’s instructions for any local requirements and disposal guidance.

Where it falls short

- Not a substitute for full insulation: On long exposed runs, this won’t give you the thermal performance of proper foam or fiberglass insulation. Use it as a complement, not a wholesale replacement.

- Sensitive to poor prep: If the pipe is sweating, dirty, or oily, adhesion suffers. This is not a “spray and walk away” fix in active condensation.

- Messy if you rush: The product isn’t hard to use, but it rewards patience and masking. In tight mechanical closets, plan your sequence before you spray.

Practical use cases I’d reach for again

- Sealing the seams and fittings after installing split foam sleeves, especially around elbows and tees.

- Coating service valves and strainers on refrigeration lines where sweat collects and drips.

- Treating a toilet tank’s cold zone or a short, exposed cold-water stub under a sink that weeps in humid weather.

- Touching up gaps left by bulky wraps around hangers and clamps.

Who will appreciate this most

- HVAC and maintenance techs who deal with persistent sweating at valves and fittings.

- Homeowners tired of mopping up under a bathroom sink or AC air handler.

- Facility teams in hospitals and schools who need a cleanable, paintable finish around sensitive equipment.

Final thoughts and recommendation

PipeWrap spray won me over as a targeted, practical way to stop condensation where wraps and sleeves struggle. It bonds well to a range of materials, builds into a flexible, paintable shell, and, most importantly, keeps fittings and valves dry once cured. It demands decent surface prep and thoughtful masking, and it won’t replace proper insulation on long runs—but used as intended, it’s effective and efficient. I recommend it for anyone who needs reliable anti-condensation control on complex geometries, wants a finish that can be painted to match surroundings, and values a tool that complements (rather than replaces) traditional insulation.

Project Ideas

Business

Targeted Anti-Sweat Retrofit Service

Offer a specialty service to landlords, property managers and condos: identify vulnerable fittings/valves and apply targeted spray-on insulation to stop pipe sweating and dripping. Faster and neater than traditional wrap, this service reduces water damage claims and tenant complaints—sell as a one-off retrofit or part of preventive maintenance packages.

Restaurant & Commercial Kitchen Maintenance Niche

Market a condensation-control contract to restaurants, cafeterias and food-service facilities for non-food-contact areas (mechanical rooms, refrigeration lines, drain fittings). Emphasize quick application, non-flammable when dry, and approval for non-food-contact environments to minimize downtime and compliance worries.

Pre-Coated Fittings for HVAC/Plumbing Contractors

Partner with local HVAC and plumbing contractors to supply or pre-spray common valves, elbows and threaded fittings so installations are faster and protected from day one. Offer bulk pre-coating, labeled parts, and on-site touch-up services—position as a time-saver that reduces callbacks for condensation issues.

DIY Kits + Online Tutorial Series

Create branded DIY kits (small cans, gloves, respirator guidance, templates) and sell them through an ecommerce shop or local hardware stores, bundled with step-by-step video tutorials for homeowners and makers. Offer upsells like color packs, texture guides, and virtual consultation for tricky applications.

Historic Building & Retrofit Consultancy

Specialize in discreet condensation solutions for historic and commercial properties where visible bulk insulation is unsuitable. Use the spray to insulate tight fittings and joints with minimal visual impact and provide documentation showing compatibility with common substrates and safety for mechanical areas—charge premium consulting and project management fees.

Creative

Steampunk Pipe Lamp & Light Fixtures

Use the spray to build textured, paintable coatings on copper/steel pipe lamp bodies and fittings. The foam bonds to metal and PVC, so you can create layered, ribbed or riveted-looking surfaces, sand or carve details after drying, then paint metallics and patinas for true steampunk/industrial lighting.

Weatherproof Garden Sculptures

Coat metal, PVC or ceramic garden pieces to make them water-resistant and durable outdoors. The flexible, paintable finish prevents corrosion and can be colored to mimic stone, rust or enamel—great for transforming salvaged plumbing parts into long-lasting yard art.

Custom Insulating Handles & Grips

Form ergonomic tool handles, mug sleeves or bicycle grips by spraying over shaped cores (wood dowels, foam, or PVC forms). The material dries to a comfortable, flexible insulating layer that bonds to common substrates and can be trimmed, textured and painted for custom finishes.

Faux-Stone Columns and Architectural Accents

Build column wraps, corbels or pipe-clad architectural details by layering the spray over a light framework (cardboard, foam or thin PVC). Sculpt or texture the surface while curing, then paint with masonry faux finishes to create durable, lightweight decorative columns and trims.

Concealed Condensation-Free Planter Liners

Spray the interior of metal or ceramic planters to create a water-resistant liner that prevents root-chilling condensation and metal corrosion. Because it bonds to porcelain and metals and dries flexible, it’s ideal for repurposed containers and can be painted on the exterior for seamless aesthetics.