Features

- MULTIPLE APPLICATIONS: MC Cable used for branch, feeder and service for distribution in commercial, industrial and multi-residential construction

- ALUMINUM JACKET: Aluminum armored for protection

- THHN AMPERE RATING: Rated for 55 Amps

- STANDARDS: Meets UL 83, 1569, 1581 and 2256

- STRANDED COPPER: Conductors are made of soft annealed copper

Specifications

| Color | Aluminum |

| Size | 50Ft Cut |

| Unit Count | 1 |

Related Tools

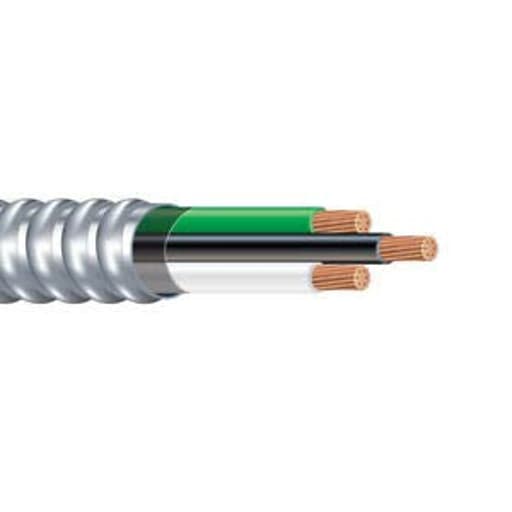

8/2 metal-clad (MC) cable with ground, 50 ft length, contains stranded soft-annealed copper conductors with an aluminum armored jacket for mechanical protection. It is rated for 55 A (THHN ampacity) for use in branch, feeder, and service distribution in commercial, industrial, and multi-residential construction, and meets UL 83, 1569, 1581, and 2256.

Stock Wire 8/2 Metal Clad (MC) Cable with Ground, Aluminum Armored, Stranded Copper Conductors Review

Why I chose this cable

I picked up this 8/2 MC cable for a 240V, 40A branch circuit to a garage EV charger and a couple of heavy-duty shop receptacles. I wanted something code-compliant for exposed runs in a finished basement and garage without the hassle of bending EMT or pulling conductors through flex. This aluminum-armored, stranded-copper MC hit that sweet spot: tough enough to protect the conductors, light and flexible enough for a one-person install, and properly listed for commercial/industrial environments if I need to re-use it later on another project.

What you get

- Construction: Two 8 AWG stranded, soft-annealed copper conductors plus an equipment grounding conductor, inside interlocked aluminum armor.

- Ratings: THHN ampacity listing of 55A (as always, final ampacity and overcurrent protection depend on the temperature rating of terminations and the application).

- Listings/standards: UL 83, 1569, 1581, and 2256.

- Length: 50 feet, factory cut.

- Color/finish: Natural aluminum armor.

In practical terms, this is a robust 8/2 with ground that’s meant to be stapled/strapped and terminated with MC connectors, offering protection similar to a raceway without having to bend pipe or fish.

Build quality and handling

The armor is interlocked aluminum, which keeps weight down and won’t rust. It’s still firm enough to protect the conductors against casual impacts during install. I’ve used steel-jacket MC plenty of times, and for many indoor applications this aluminum version is simply easier to work with. It holds shape when you dress it along a wall, but you can still coax it around gentle bends without fighting it.

The stranded copper conductors are the right call at 8 AWG—they land more easily in breaker and disconnect lugs than solid wire and reduce stress at termination points. The insulation arrived clean, with crisp gauge/markings.

I cut the jacket using a Roto-Split style MC cutter, which gave me clean rings without nicking the insulation. You can use a hacksaw in a pinch, but I’d strongly recommend a proper cutter to avoid jagged edges and time-consuming prep. After cutting, I slid on anti-short bushings at terminations (some inspectors will insist, and they’re good practice anyway).

Coil memory was manageable. The 50-foot cut came coiled tight but not kinked. Once I unrolled it and reverse-wrapped a couple of loops, it laid flat enough to strap to joists and along a garage wall.

Installation notes

- Connectors and boxes: Use 1/2-inch MC connectors sized for 8 AWG MC. The cable’s outside diameter is bigger than 12/2 MC, so grab fittings specifically rated for 8 AWG MC to keep it snug and code-compliant. Terminate into standard metal boxes or panel knockouts; bond per the fitting’s instructions.

- Support spacing: Follow your local code, but MC generally needs support at intervals not exceeding 6 feet, with support within 12 inches of each box. I used standard one-hole straps for clean runs.

- Bend radius: Keep bends broad and smooth. It’s fairly pliable for 8 AWG, but don’t force tight 90s against studs. Pre-shape it by hand before strapping.

- Cutting/prep: Score with an MC cutter, snap a link, remove the ring, deburr if necessary, and insert anti-short bushings. The aluminum jacket cuts easily; just don’t over-tighten the cutter and risk nicking insulation.

- Terminations: The stranded conductors seated well in modern breaker lugs. Always verify lug torque and compatibility with stranded copper at 8 AWG.

In my install, I ran about 35 feet from panel to a garage disconnect, then to a wall-mounted EVSE. Strapping was quick, the armor protected the cable nicely along exposed portions, and the connectors seated solidly with no play.

Electrical performance and suitability

With THHN-rated conductors and a listed ampacity of 55A for 8 AWG copper, this cable is well-suited for:

- 240V, 40A continuous loads (EVSE at 40A on a 50A breaker, subject to 125% continuous load rule and termination temperature ratings).

- 240V, up to 50A non-continuous loads where 8 AWG is appropriate.

- Heavy-duty 240V appliances without a neutral (e.g., many water heaters, air compressors, some welders).

Note the limitation in the “8/2” designation: you get two insulated conductors plus a ground. If your load requires a neutral, you need 8/3 MC instead. That’s a common point of confusion—this cable is perfect for straight 240V two-wire circuits, but it won’t serve ranges or EVSEs that require a neutral conductor.

Voltage drop at this gauge is favorable for short runs. At 40A over 50 feet, you’re in excellent shape. If you push beyond 100–150 feet, calculate voltage drop and consider upsizing.

Indoor, outdoor, and wet locations

The armor is aluminum, which resists rust, and the conductors are typically THHN/THWN-2 in most modern MC. The product’s literature highlights THHN ampacity; check the jacket printing on your reel for the exact wet-location rating of the conductors you receive. If the conductors are marked THWN or THWN-2, and your local code allows, you can use it in wet locations and outdoors when properly supported and terminated. If the printing only shows THHN, keep it to dry/damp locations. Either way, this is not direct-burial cable.

For general indoor exposed runs (basements, garages, workshops) and commercial ceilings or corridors where MC is permitted, it’s right at home.

Standards and code confidence

The listings—UL 83 (thermoplastic insulated wires), UL 1569 (metal-clad cable), UL 1581 (electrical wire testing), and UL 2256—give confidence that you’re working with a properly evaluated cable. As always, coordinate conductor ampacity with the temperature rating of terminations (commonly 75°C), size your breaker accordingly, and follow NEC and local amendments for support and fittings. If you’re installing in healthcare, plenum, or other special occupancies, verify whether you need a specialty MC variant (HCF, plenum-rated, fire-resistive).

How it compares to alternatives

- Versus NM-B (Romex): NM-B is cheaper and fine for many residential interiors but must be protected where exposed and isn’t allowed in many commercial/industrial spaces. This MC cable is more rugged, can be run exposed in many settings, and looks cleaner on the wall.

- Versus EMT/flex with pulled conductors: Conduit systems are flexible in layout and conductor count, and are great for future changes. But for a straight, single run, MC is faster—no pipe bending, no wire pulling. For one-off circuits like a garage EVSE feed, MC usually wins on labor.

- Versus steel-jacket MC: Steel armor is tougher but heavier. For indoor general use, the aluminum armor is easier on the installer without giving up meaningful protection.

Durability over time

Armor seams are uniform, and the aluminum won’t corrode like ferrous metals in normal indoor environments. I don’t expect jacket creep or kinking under normal strap spacing. The stranded copper gives you a bit of flex at terminations, reducing stress compared to solid. Provided it’s supported correctly and fittings are snug, it should remain serviceable for decades.

Minor drawbacks

- Not a “universal” feed: Without a neutral, it’s limited to two-wire 240V loads. Plan accordingly.

- Fitting selection matters: You’ll want connectors sized for 8 AWG MC; don’t try to force 3/8-inch “small” MC fittings intended for 12/2 or 14/2. Stock the right 1/2-inch trade-size MC connectors before you start.

- Wet-location clarity: The marketing mentions THHN ampacity. Most MC of this type I encounter is THHN/THWN-2, but confirm the jacket markings on your actual coil before using it in wet or outdoor locations.

Who it’s for

- Electricians and experienced DIYers adding a 240V, 40–50A circuit for EV charging, a condenser disconnect, a water heater, or shop equipment—especially where the run will be exposed.

- Small commercial jobs where MC is standard and labor savings over conduit are attractive.

- Retrofits where bending conduit would be awkward or time-consuming.

If you need a neutral or foresee adding one later, choose 8/3 MC instead. If you’re running through corrosive or specialty environments, verify you have the appropriate MC variant for that occupancy.

Bottom line and recommendation

This 8/2 MC cable with aluminum armor and stranded copper conductors is a practical, installer-friendly choice for robust 240V circuits up to 55A conductor ampacity, subject to code and termination ratings. It’s light, easy to shape, and fast to terminate compared to conduit, with the durability to run exposed in many residential garages and commercial settings. My install went quickly, terminations were clean, and the finished run looks professional.

I recommend this cable. It strikes the right balance of protection, flexibility, and performance, and it’s well-suited to the kinds of mid-ampacity 240V circuits many of us are adding today. Just confirm your conductor markings for wet locations, pick the correct MC fittings, and ensure your load doesn’t need a neutral. For the intended use—straightforward, two-wire 240V feeds—it’s an efficient, code-friendly solution that saves time without compromising quality.

Project Ideas

Business

Custom Industrial Lighting Brand

Create a line of bespoke pendant and wall fixtures that use MC cable as the signature material. Offer standard models plus custom-length options and finishes. Sales channels: Etsy, Shopify, Instagram, local interior designers. Monetization: set product tiers (basic, premium with dimmable LED drivers, custom finishes) and offer installation add-ons or code-compliant options through local electricians.

Upcycled Hardware & Furniture Collection

Design a small product line—shelves, coat racks, table edge trims, and handles—centered on armored-cable accents. Target loft/industrial interiors and boutique retailers. Sell direct-to-consumer and wholesale to local shops or staging companies. Add value by offering matching kits (brackets, screws, end caps) and curated finishes.

Contractor/Designer Supply Kits

Assemble pre-cut, finished MC-cable kits for architects, contractors, and designers who want the exposed conduit look without on-site fabrication. Kits can include pre-terminated ends, mounting hardware, and finish options. Market the kits through trade shows, online ads targeted to pros, and partnerships with electrical supply stores—position as time-savers that retain a handcrafted look.

Workshops & DIY Experience Kits

Run paid workshops or virtual classes teaching makers how to transform MC cable into lights, racks, or furniture accents. Sell takeaway kits (50 ft cable plus connectors, sockets, mounting hardware) so attendees can finish projects at home. Revenue streams: ticket sales, kit sales, repeat classes, and corporate team-building events.

Creative

Industrial Pendant Lights

Cut the 8/2 MC into pendant-length runs and use the aluminum armored jacket as the visible conduit housing for vintage-style sockets or LED retrofit bulbs. The stranded copper conductors can carry the fixture feed (or be removed and replaced with low-voltage drivers if preferred). Finish options: leave raw aluminum for a patina, brushed polish, or paint for a colored industrial look. Tip: mount with matching metal canopies and strain reliefs for a cohesive aesthetic.

Braided Metal Rope & Handles

Strip back the armor or split it lengthwise and braid the stranded copper (or use the armored jacket itself) into flexible, heavy-duty rope for drawer pulls, cabinet handles, railings, or sculptural elements. The result is a strong, tactile industrial strap that reads like reclaimed hardware but is uniform and durable.

Exposed-Edge Shelving and Brackets

Use short sections of the aluminum armored cable as external shelf edges, trim, or bracket arms. Secure them to wood or metal shelves so the armor becomes a continuous accent that conceals fasteners and gives a workshop-to-loft vibe. The armor’s profile also protects shelf edges and hides wiring if you choose to add integrated lighting later.

Integrated Coat Rack with Lighting/USB

Build a wall-mounted coat rail from lengths of MC cable, incorporating interior conductors to power low-voltage LED strips above the rail and a small USB/charging module at one end. The armoring acts as the structural rail, and the concealed conductors feed the lighting module. This creates a functional statement piece: hang coats while charging phones and adding ambient light.