When setting up workshop lighting, the goal is to create a safe, productive, and comfortable workspace. Poor lighting can lead to accidents, errors, and fatigue, while a well-lit workshop improves visibility, reduces mistakes, and enhances focus. Here's what you need to know:

- Brightness (Lumens): Aim for 70–100 lumens per square foot based on your workshop size and tasks. For example, a 192 sq. ft. space needs at least 13,440 lumens.

- Color Temperature: Use cooler light (4,000K–5,000K) for general tasks and brighter tones (5,000K–6,500K) for precision work.

- CRI (Color Rendering Index): Choose lights with a CRI of 80+ for accurate color representation, crucial for detailed tasks like painting or wiring.

- Fixture Types: LEDs are the most efficient and durable choice, outperforming fluorescent and incandescent options in energy use, lifespan, and heat output.

- Layered Lighting: Combine ambient (general), task (focused), and accent (highlighting) lighting to cover all needs.

- Placement: Position fixtures to minimize shadows and glare. Use diffusers or indirect lighting for even coverage.

- Power Planning: Ensure your electrical system can handle the load, keeping circuits under 80% capacity.

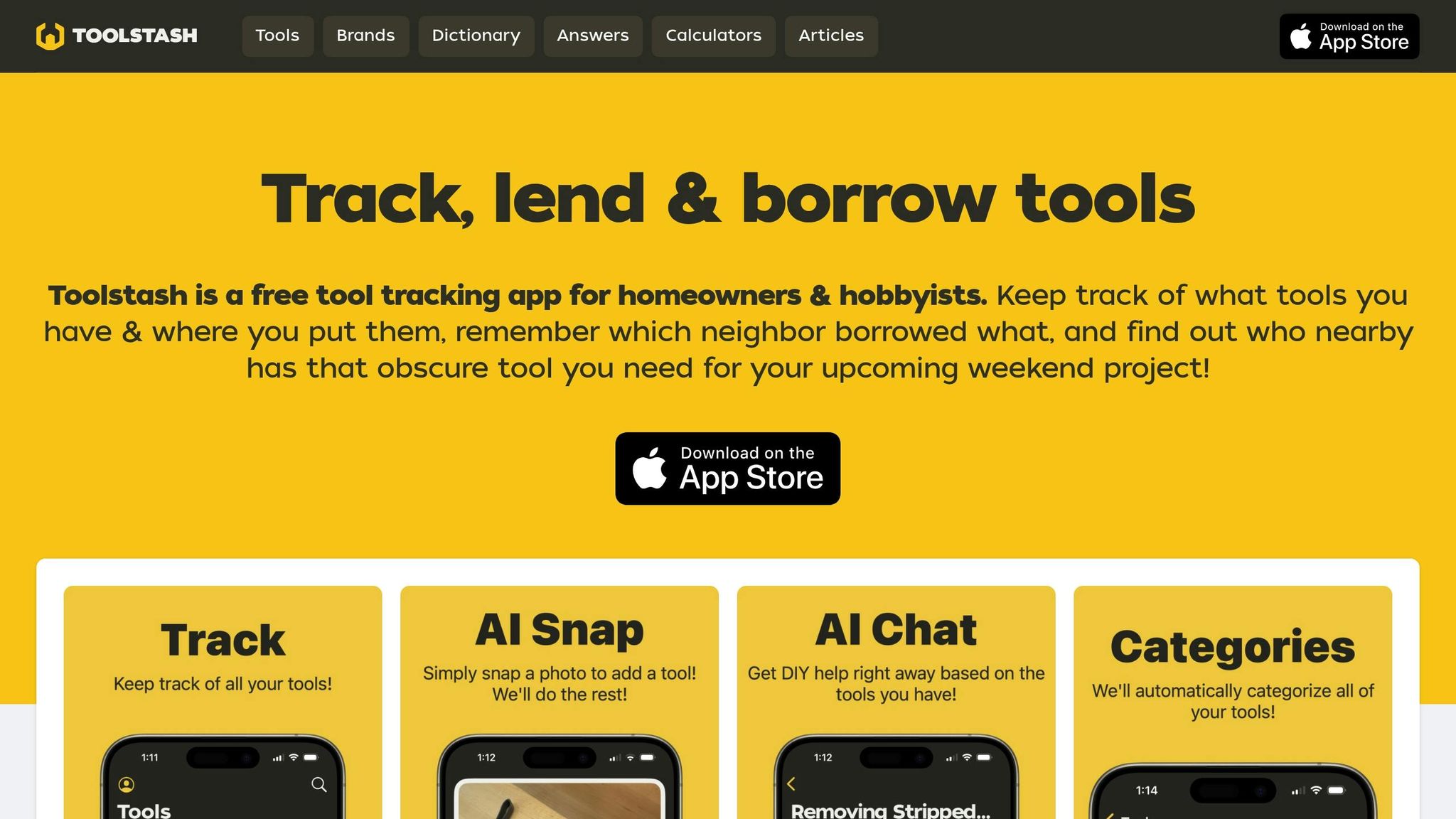

For tough environments, choose fixtures rated for dust and moisture (IP65+). Tools like Toolstash can simplify tracking, maintaining, and upgrading your lighting setup.

Pro Tip: Start by calculating your lumen needs, then layer lighting types for optimal results. LEDs save energy and last longer, making them the best choice for most workshops.

How to Design a LED Garage / Shop Lighting Layout - Part 1 Lumen Design

Workshop Lighting Basics

When it comes to workshop lighting, two key factors are crucial: ensuring there’s enough brightness for safety and productivity, and creating a comfortable, balanced environment for extended use[3].

Lumens and Light Levels Explained

Lumens measure how much visible light a fixture produces - the higher the lumens, the brighter the space[1]. For workshops, the general guideline is 70–100 lumens per square foot for ceilings around 8 feet high. This range ensures sufficient light for most tasks while maintaining safety standards. To calculate the total lumens needed, multiply your workshop’s square footage by the recommended lumens per square foot. For instance, a 200-square-foot workshop requiring 80 lumens per square foot would need 16,000 lumens in total. If you’re using LED fixtures that produce 4,000 lumens each, you’d need four fixtures to achieve this[1].

Different tasks demand varying light intensities. General areas can stick to the baseline recommendation, but workstations for detailed tasks - like woodworking or electronics - often require additional, focused task lighting. This helps improve visibility for intricate work and reduces eye strain[2]. Once you’ve addressed brightness, the next step is refining the quality of light through color temperature and CRI.

Color Temperature and CRI for Workshops

Color temperature, measured in Kelvins (K), determines the tone of the light, ranging from warm yellow to cool blue-white hues. Workshops typically benefit from cooler light in the 4,000K–5,000K range, which offers bright white illumination ideal for visibility and precision[4]. For areas where focus and detail are critical, like task-heavy stations, lighting in the 5,000K–6,500K range creates an alert and efficient workspace[5].

Another important factor is the Color Rendering Index (CRI), which gauges how accurately a light source displays colors compared to natural sunlight. A CRI of 80 or higher ensures that colors appear true to life, making it easier to distinguish details - especially important for tasks like painting, wiring, or fine woodworking[4]. With these elements in place, it’s essential to address shadows and glare for a fully optimized lighting setup.

How to Reduce Shadows and Glare

To minimize shadows and glare, combine different types of lighting and layer ambient lighting with task lighting[2]. Position multiple fixtures at various angles and use diffusers or indirect lighting to soften harsh shadows. Avoid placing lights directly above or behind work areas, as this can create disruptive shadows. Instead, aim for even illumination across your workspace.

Indirect lighting - such as bouncing light off walls or ceilings - can also make the environment more comfortable. For workshops with reflective surfaces, like metal workbenches or shiny tool cabinets, carefully position ambient lights and consider adjustable fixtures to manage reflections. Additionally, the beam angle of your lights matters: wide beam angles work well for general illumination, while narrow beams are better for focused tasks. By combining these approaches, you can create a balanced lighting layout that reduces glare and shadows, complementing the brightness and quality standards discussed earlier[5]. This ensures every part of your workshop is well-lit and functional for its specific purpose.

Types of Workshop Lighting Fixtures

Choosing the right lighting for your workshop can make a big difference in functionality and comfort. Different fixtures cater to specific needs, and understanding their benefits can help you create an efficient and safe workspace.

LED vs. Fluorescent vs. Incandescent Lighting

The type of lighting technology you choose lays the groundwork for your workshop's overall efficiency. Here’s how the three main options compare:

LED fixtures have become the go-to choice for workshops. They consume up to 75% less energy than incandescent bulbs and 30–50% less than fluorescent lights. Plus, their lifespan ranges from 25,000 to 50,000 hours, far surpassing the 7,000–15,000 hours of fluorescents and the mere 1,000 hours of incandescents[4]. This longevity means fewer replacements and lower maintenance costs. LEDs also produce very little heat, making them safer around flammable materials and more comfortable for extended use. They reach full brightness instantly, offer excellent dimming capabilities (when paired with compatible controls), and often feature linkable designs for easier installation[1].

Fluorescent fixtures were once a popular choice due to their brightness and lower upfront cost - typically $15–$40 per fixture compared to the $20–$80 for LEDs. However, they contain mercury, requiring careful disposal, and don’t perform well in cold environments, which can limit their usefulness in certain workshop settings[4].

Incandescent lighting is now largely phased out in workshops. Its low energy efficiency, high heat output, and short lifespan of about 1,000 hours make it impractical for spaces requiring reliable and consistent lighting[4].

| Feature | LED | Fluorescent | Incandescent |

|---|---|---|---|

| Energy Efficiency | High | Moderate | Low |

| Lifespan (hours) | 25,000–50,000 | 7,000–15,000 | 1,000 |

| Heat Output | Low | Moderate | High |

| Upfront Cost | $20–$80 | $15–$40 | Low |

| Maintenance | Minimal | Moderate | High |

While general lighting is essential, specialized fixtures can help fine-tune your workspace for specific tasks.

Task Lights and Specialty Workshop Fixtures

Task lighting is perfect for focusing on specific work areas. Adjustable desk lamps with articulating arms let you direct light exactly where it’s needed. Under-cabinet LED strips are great for eliminating shadows from overhead lights, and magnetic base lights provide portability, making them ideal for temporary setups or moving between projects[2]. Position task lights carefully near work surfaces to reduce shadows and improve visibility for detailed tasks.

Specialty fixtures like hexagonal and square LED panels offer uniform, shadow-free lighting while adding a sleek, modern touch to your workshop. These panels can be arranged in customizable patterns and often feature linkable designs for easy expansion.

For added flexibility, battery-powered LED units are a great option, especially for hard-to-reach areas or outdoor projects. Look for models with adjustable stands, magnetic bases, or hanging hooks to maximize their versatility. Smart lighting options can also enhance your workspace by allowing remote control, scheduling, and dimming. Pairing these with platforms like Toolstash can streamline your lighting setup even further[2].

Fixtures for Dusty and Damp Conditions

If your workshop is exposed to dust, metal shavings, or moisture, durability becomes a top priority. Fixtures designed for tough conditions, like those with an IP65 rating or higher, are dust-tight and protected against water jets, ensuring safe operation in challenging environments[4].

Vapor-tight fixtures are particularly useful, featuring sealed housings that keep out dust and moisture. These fixtures typically cost between $50 and $150, depending on size and features, but their durability and low maintenance needs make them a worthwhile investment[4]. Look for labels like "weatherproof" or "wet location rated" to ensure the fixture is suitable for your workspace.

LEDs are especially well-suited for harsh environments. Their solid-state design resists vibration and impact better than traditional bulbs, making them less prone to breakage - an important feature when working near power tools. Additionally, smooth-surfaced fixtures are easier to clean and resist dust buildup, which helps maintain optimal light output with minimal effort[2].

For spaces like woodworking shops, metalworking facilities, or garages where both dust and moisture are common, investing in properly rated fixtures ensures consistent lighting performance and reduces the need for frequent replacements.

Where to Place Your Lights

Getting the placement of your lights right is just as important as figuring out how many lumens you need. Proper positioning ensures your workspace is evenly lit, reduces shadows, and makes it easier to tackle projects efficiently.

How to Calculate Fixtures and Lumens Needed

Once you've calculated how many lumens your workshop needs, the next step is determining how many fixtures to install. Start by measuring the dimensions of your workshop to determine its square footage. Multiply that number by the recommended lumens per square foot. For example, a 12′ × 16′ workshop (192 sq ft) with a 70-lumen-per-square-foot guideline requires about 13,440 lumens. If you’re using 3,500-lumen fixtures, you’ll need four of them (13,440 ÷ 3,500 ≈ 3.84) [1].

If your workshop has higher ceilings, you might need fixtures with greater output or to position them closer to work areas. Lower ceilings, on the other hand, may allow you to use fewer fixtures while maintaining effective lighting.

Setting Up Task, Ambient, and Accent Lighting Zones

A well-lit workshop combines different types of lighting - ambient, task, and accent - to create a functional and comfortable environment [2].

- Ambient lighting: This is your primary light source, designed to illuminate the entire space evenly. Overhead LED panels or shop lights are great options, and they should be spaced evenly across the ceiling to eliminate dark spots.

- Task lighting: For detailed work, task lighting provides focused, shadow-free illumination. Adjustable desk lamps, under-cabinet LED strips, or magnetic base lights are excellent choices for workbenches or areas where precision is key.

- Accent lighting: Use this to highlight specific areas, like tool displays or finished projects. It adds depth and a touch of personality to your workshop.

If your workshop has windows, take advantage of natural light during the day and balance it with your artificial lighting. Once you’ve identified your lighting zones, you can choose the best installation method to suit your setup.

Installation Methods: Hardwired vs. Plug-in

Your choice of installation method depends on how permanent you want your lighting to be, your workshop’s electrical setup, and your comfort level with DIY projects.

- Hardwired fixtures offer a polished, permanent look and can handle higher electrical loads. However, they require running wiring through the ceiling and connecting to the electrical panel, which often means hiring a licensed electrician.

- Plug-in fixtures are simpler and more flexible. They’re ideal for smaller workshops or temporary setups and can be positioned where outlets are available. Linkable plug-in fixtures are particularly handy for larger workshops, as they can be daisy-chained to minimize wiring hassles [1].

| Installation Method | Best For | Considerations |

|---|---|---|

| Hardwired | Permanent setups, high-power needs | Requires an electrician, less flexible |

| Plug-in (Individual) | Small or temporary setups | Limited by outlet locations |

| Plug-in (Linkable) | Larger workshops, DIY-friendly | Easy to expand, needs one outlet |

Daisy-chaining lets you connect multiple plug-in fixtures in a series so a single outlet can power an entire row of lights [1]. When planning placement, avoid putting fixtures directly above where you stand to minimize shadows. Instead, offset them or use multiple fixtures at different angles for even coverage [2].

For added flexibility, consider adjustable fixtures or smart lighting systems. These let you control brightness, set schedules, and even manage lighting zones remotely. If you’re working with a larger space, tools like Toolstash can help you track fixture placement, plan upgrades, and stay on top of maintenance.

Power Management and Using Toolstash

Managing power effectively is crucial for ensuring safety, keeping your fixtures running smoothly, and controlling costs. Building on earlier discussions about fixture placement and lumen calculations, proper electrical planning is key to keeping your lighting system both safe and efficient.

Planning Your Electrical Power Needs

Before installing any lighting, it's important to calculate the total electrical load for your workshop. In the U.S., household circuits typically provide 15 or 20 amps at 120 volts, which translates to 1,800 or 2,400 watts. However, the National Electrical Code (NEC) recommends using only 80% of a circuit's capacity - 1,440 watts for a 15-amp circuit and 1,920 watts for a 20-amp circuit.

For instance, a 20'×30' (600 sq. ft.) workshop needing 80 lumens per square foot would require 48,000 lumens in total. If you use 5,000-lumen, 50-watt LED shop lights, ten fixtures would consume 500 watts - well within the limits of a 15-amp circuit, even with a bit of extra load.

LEDs are a great choice for this kind of setup because they are far more energy-efficient. For example, a 9-watt LED can replace a 60-watt incandescent bulb while delivering similar brightness, significantly cutting down on power consumption.

To avoid overloading circuits, be sure to account for all tools and equipment in your calculations. Leave some extra capacity for future needs, and if you're unsure about your current wiring or need additional circuits installed, it's smart to consult a licensed electrician. Investing in professional help ensures safety and compliance with electrical codes.

For workshops in damp or dusty environments, make sure to use GFCI (Ground Fault Circuit Interrupter) outlets and fixtures rated for those conditions. Regularly inspect your wiring and lighting fixtures to keep them in good working order.

Once you've mapped out your power needs, it's time to focus on tracking and maintaining your lighting setup, and that's where Toolstash comes in.

Managing Lighting with Toolstash

After ensuring your electrical load is properly managed, Toolstash can help you organize and monitor your lighting system. This platform simplifies the process of keeping track of fixtures and components with a range of helpful features.

Toolstash allows you to inventory every part of your lighting system - fixtures, bulbs, switches, and other components. Its AI Snap feature makes cataloging easy: just take a photo of a new purchase, and the system automatically logs the model number and specifications. You can group items into categories like "Overhead Lighting" or "Task Lighting" for better organization.

Details like lumens, color temperature, CRI, purchase dates, and warranties can also be recorded. This makes upgrades and troubleshooting a breeze - you'll always know when you bought that flickering LED panel and whether it’s still under warranty.

The platform also helps you track where spare bulbs, task lights, or electrical components are stored. No more wasting time rummaging through drawers for a replacement bulb or circuit tester.

Toolstash’s AI chat assistance is another standout feature. It offers DIY help tailored to your inventory. For example, if you need installation instructions for a fixture you added months ago, the system can pull up specific guides and troubleshooting tips based on your items - not generic advice.

If your workshop uses smart lighting controls like motion sensors, dimmers, or schedulers, Toolstash can track these devices too. It logs connectivity details (e.g., Wi-Fi or Zigbee), reminds you to update firmware or replace batteries, and even analyzes usage patterns to spot energy-saving opportunities. It can also help integrate smart lighting with other connected devices in your workshop.

Planning for future upgrades becomes much simpler when all your current setup details are documented. Toolstash can notify you about new LED advancements, track the lifespan of your fixtures, and help you budget for replacements. When expansion or upgrades are needed, you'll have access to wiring diagrams, fixture locations, and electrical load calculations.

If you lend or borrow tools like circuit testers or temporary work lights, Toolstash keeps track of who has what and when it's due back.

Finally, Toolstash provides detailed reports on key metrics like total lumens, energy consumption (kWh), fixture lifespan, and maintenance history. This data helps you optimize performance, reduce energy costs, and stay compliant with safety standards. Plus, it ensures you can demonstrate proper maintenance when needed, supporting the comprehensive lighting strategy outlined in this guide.

Conclusion

Designing workshop lighting isn’t just about installing fixtures - it’s about creating an environment that enhances productivity, safety, and comfort. As highlighted in this guide, thoughtful lighting can directly impact the quality of your work and how much you enjoy doing it.

For instance, studies show that well-planned lighting can reduce workplace accidents by up to 60% and improve task performance by 10–50% [2][6]. Achieving this starts with understanding your space’s needs. Calculating lumen requirements (usually 70–100 lumens per square foot) is a great first step. From there, layering ambient, task, and accent lighting ensures comprehensive coverage, while energy-efficient LED fixtures help keep costs down [1][2].

Don’t overlook the importance of proper maintenance. LEDs not only cut energy consumption by up to 75%, but they also last 25 times longer than traditional incandescent bulbs [4]. Regular upkeep ensures you continue to reap these benefits while maintaining optimal lighting conditions.

Modern tools like Toolstash can simplify the process. They help you track your lighting setup, schedule maintenance, and even provide AI-driven suggestions for improving your system. These tools make it easier to stay on top of your lighting strategy.

To get started, assess your current setup. Identify areas with poor visibility or shadows, calculate your total lumen needs, and plan fixture placement to reduce glare and eliminate dark spots. Make sure your electrical system can handle the load, and you’ll be well on your way to transforming your workshop’s lighting.

Good lighting isn’t just about seeing better - it’s about working smarter, staying safer, and feeling more comfortable in your space. Investing in a well-designed lighting system pays off with better work quality, reduced fatigue, and a workspace that truly supports your craft.

FAQs

How do I figure out the number of light fixtures my workshop needs based on its size and brightness requirements?

To figure out how many light fixtures your workshop needs, start by determining the total lumens required for the space. A good rule of thumb for workshops is 50 to 100 lumens per square foot, depending on the type of work you’ll be doing. Multiply your workshop's square footage by the desired lumens per square foot to calculate the total lumens needed. Then, check the lumen output of the light fixtures you're considering. Divide the total lumens by the output per fixture to estimate how many you’ll need.

Here’s an example: If your workshop is 200 square feet and you want 75 lumens per square foot, you’ll need a total of 15,000 lumens. If each light fixture produces 3,000 lumens, you’d need five fixtures to achieve the required brightness.

Don’t forget to account for factors like ceiling height, fixture placement, and the type of lighting (e.g., task lighting or general ambient lighting) to ensure the space is evenly and effectively lit.

What are the benefits of layered lighting in a workshop, and how can I set it up effectively?

Layered lighting not only improves visibility but also reduces eye strain and makes your workspace more practical and inviting. By blending ambient, task, and accent lighting, you can customize your setup to match different activities and boost overall productivity.

Start with ambient lighting - this serves as the base layer. Overhead fixtures or LED panels work well to provide consistent, general illumination across the space. Next, incorporate task lighting in areas where detail work happens, like workbenches or tool stations. Adjustable lamps or under-cabinet lights are great options for focused lighting in these spots. Finally, use accent lighting to draw attention to specific tools or areas, while also giving your workshop a bit of character. When setting up your lighting, think about the layout and how you use the space to ensure everything is well-placed and functional.

Why is the Color Rendering Index (CRI) important for workshop lighting, and how does it impact the quality of tasks performed?

The Color Rendering Index (CRI) is a metric that shows how well a light source reveals the true colors of objects compared to natural daylight. In workshops, where precision is key, lighting with a high CRI (typically 80 or higher) plays an important role. It ensures better visibility and accurate color perception, which is critical for tasks like painting, woodworking, or making precise repairs.

Lighting with a low CRI can distort colors, making it harder to distinguish between materials and potentially causing mistakes or slowing down progress. Opting for high-CRI lighting helps create a workspace that promotes accuracy, efficiency, and comfort, allowing you to focus on delivering quality results.